AVEVA launches a powerful new application for governing asset information using a standards-based methodology

Cambridge, UK– 30 July 2014 Today AVEVA announced the launch of AVEVA Information Standards Manager (AVEVA ISM), a software product that enables both EPC contractors and asset Owner Operators to achieve greater control over critical engineering information across their projects and enterprises. It does this by rationalising existing class libraries and imposing consistent and compliant standards that improve information quality and reduce both project and operational risk.

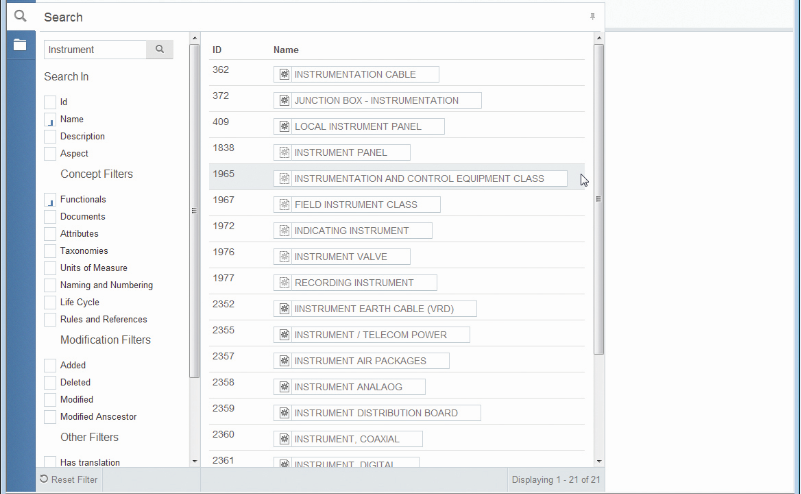

AVEVA ISM can be rapidly deployed and is fully compatible with software systems from other vendors. With today’s massively increasing quantities and variety of asset life cycle information, this powerful enterprise-level application offers increased value to both project and operations management processes without the need to replace existing authoring products. The quick deployment and open design of AVEVA ISM delivers rapid ROI to EPCs and Owner Operators.

‘AVEVA ISM is able to establish and govern all asset information standards, across any number of projects, and is easier to implement and maintain than any competitive solution,’ explained Derek Middlemas, COO and Head of Enterprise Solutions, AVEVA. ‘This launch strengthens AVEVA’s Digital Information Hub capabilities, and like all AVEVA’s solutions, has been built around the principle of creating and maintaining an accurate Digital Asset.’

Using AVEVA ISM, Owner Operators benefit by being able to fully and accurately communicate their information standards requirements to their contractors, who are thus able to execute projects more quickly and to the necessary contractual standards. Contractors who work with multiple clients, each with their unique information standards requirements, can more easily manage concurrent projects to different standards. This enables valuable efficiency benefits, saves cost and time, and reduces opportunities for costly errors and rework.