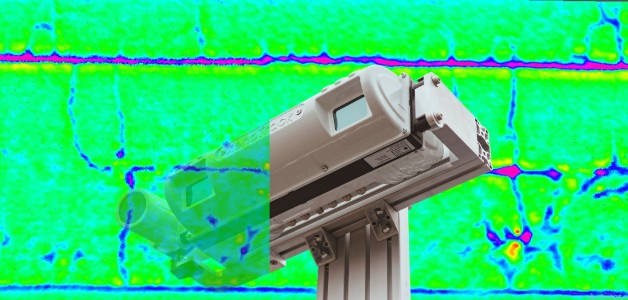

The new XT Profiler is a Class 1 longitudinal profiler designed to make advanced road inspection more affordable without compromising on accuracy or certification. The XT Profiler’s core component is a true solid state lidar that is in charge of collecting individual point clouds of the pavement surface, which are stitched to a full 3D geometry and intensity model (road markings) in the post-processing process. The XT Profiler automatically extracts longitudinal profiles at multiple transversal positions over the width of the lane.

The term “Class 1” refers to the accuracy and repeatability (submillimeter) of the measurement as defined by international standards. The XT Profiler has the same accuracy and repeatability as XenomatiX’ full 6D Road Scanning system with the 3D model being 0,45mm accurate. The main differentiator for the XT Profiler is the lane-wide 3D model it delivers, compared to a line laser or multiple single laser on a longitudinal or transversal beam (traditional profilers).

XT Profiler customers can expand the system to include lateral profiles, creating a single solution for both longitudinal and lateral profiling. Additional capabilities include IRI measurement, rutting and pothole detection, cross-slope analysis, and identification of cracks, manholes, and patches. Finally, the full 6D Road Scanning system reports all output, including the comprehensive quality index, known as the Pavement Condition Index (PCI).

Output and use cases

The XT Profiler generates a lane-wide 3D model of the pavement surface. The intuitive visualization of the 3D model gives the user detailed insight in the pavement, allowing with some experience to detect the cause and definitely the pavement repair required. Additionally, the XT Profiler automatically extracts the longitudinal profiles that the user can use to calculate the prime quality indicator IRI, using his own software or ProVAL. ProVAL also allows to study the Power Densities and other data to define the quality or pavement deterioration. Besides ProVAL, also other software packages need such profiles as input to calculate interesting condition parameters.

The goal is to obtain an objective and repeatable basic quality indicator for the road: communities, cities, counties, states and countries use such indicators to follow-up comfort and safety condition on the roads, and to budget and plan pavement repairs to safeguard these.

The XT Profiler was developed in response to growing demand from municipalities, contractors, and engineering firms seeking reliable road profiling without the complexity or investment required for full-scale systems.

The XT Profiler is easy to install on any vehicle, and provides easy and automatic data processing. The software is programmed to guide the user through the start-up process and during data collection, it controls all functionality and warns when an operational quality condition is not reached. On top, it is easy to transfer the system from one vehicle to another, and can be carried by plane from one state to another. Whereas a full-scale system comprises a turnkey vehicle setup equipped with the XT profiler and other sensors providing comprehensive pavement analysis, the XT Profiler delivers a basic surface profile to get users started, with the option for upgrades.

Compliance with international industry standards

Built on the proven 6D technology that combines 3D geometry with intensity map insights, the XT Profiler delivers professional-grade road inspection in a compact, accessible package. At its core, it uses true solid-state lidar, no point-laser or line-scan systems. This enables consistent, high-quality measurements including true zero-speed and stop-and-go profiling. The system is ICART and NCAT certified, ensuring compliance with international industry standards—an essential requirement for official road condition assessments.

iCART and NCAT are certification bodies that verify the accuracy and repeatability of a complete system output (road quality indicator), including the vehicle, the sensors and the operator. From data collection to the required IRI output is to be delivered in a time span of max 24h. Reference data, or ground truth data, are compared with the output results of the system, both on a road with known high IRI (bad and bumpy, uncomfortable and unsafe road) and known low IRI (good and flat, comfortable and safe road).

Working internationally, XenomatiX learned that there are global standards for pavement. It is important for XenomatiX to adhere to these international standards in order to deliver a high-quality product. The ICART and NCART are among the most recognized frameworks used to ensure consistency and accuracy in pavement condition measurement and reporting.

A flexible solution that enables for upgrades over time

Designed with growth in mind, the XT Profiler offers a future-proof approach to road inspection. Users can start with essential functionality and unlock additional features through upgrades as their needs evolve, no hardware replacement required. This flexibility makes the XT Profiler an ideal starting point for organizations taking their first step into automated road inspection.

Users who purchase the XT Profiler will immediately receive a highly accurate digital map of road conditions, showing which sections need repair and prioritizing them objectively, without any manual intervention. If further analysis is required, such as crack detection or calculating the Pavement Condition Index (PCI), a system upgrade will enable them to do so.