Human civilizations housing key infrastructure below the surface is certainly not a new thing, with archeologists finding evidence of clay sewer pipes near modern-day India and Pakistan dating back as far as 4000 BC. Even subterranean infrastructure as we think about it today dates back over a century, with some city’s still using at least the bones of projects completed during the Industrial Revolution in the 1800s. And as far back as the 19th century, we can find examples of this infrastructure causing problems and those in the construction industry needing information regarding the layout of what is happening below the ground.

Now well over a century later, we are still experiencing a lot of the same issues. As the construction industry continues to boom, with some projections estimating the space will be worth more than $15 trillion by 2030, bearing in mind what is happening under the surface is as important as ever. This reality can cause a lot of headaches, but the good news is that this era of explosive technological development means it doesn’t need to be.

GIS technology such as digital twins and ground-penetrating radar (GPR) scanning is being more and more widely accepted in the industry, and those working on projects – both private and public entities – that require work to be done underground must take advantage to reap the benefits in terms of safety, efficiency, finances, and setting up for the future.

As Mitchell Lidell put it in a recent talk at the Subsurface Utility Mapping Strategy Forum, “Very few major projects move forward without an environmental investigation and a geotechnical investigation, so it's not clear why there's resistance to doing a subsurface utility investigation when the immediate risk to the project and the public is considerably higher.”

Digital Twins and Scanning for Worker Safety

In any construction project, and especially those that involve often-dangerous subterranean work, safety is going to be the top priority. And in the case of this underground work, that involves the safety of both team members working on the project and the surrounding community. Given that it is, in many ways, inherently dangerous work, it’s a big ask to completely eliminate safety issues in this area, but with the scanning technology available today a lot of the issues can be mitigated, or in some cases completely eliminated.

The biggest issue on this front is around unintentional strikes of existing infrastructure. Between 2012 and 2017 in the United Kingdom, there were 318 reported injuries or fatalities resulting from strikes of electrical cable strikes. Whether it be those cables, a water main, or a gas pipe, it is of the utmost importance that construction companies and municipalities have the most current and precise information possible. For most of our history, companies relied on records from asset managers to know precise details about subterranean infrastructure, but those are often imprecise, or just simply incorrect. Often, asset managers will submit as-planned maps rather than as-built despite the frequency at which plans change. Even the slightest alteration to where a pipe is laid, or how deep it is buried, can have massive consequences when another company is ready to start a dig.

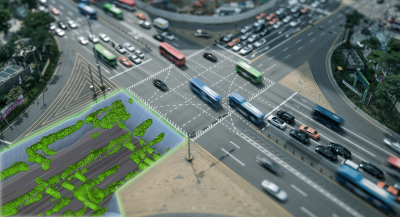

Many governments around the world are working on fixes to this issue, including the UK where they have created the National Underground Asset Register (NUAR). This is a collaborative effort between the government and asset managers of all kinds, from telecoms, utility companies, and government agencies. The goal for the program, which has run successful pilots in areas of the UK, is to create an accurate and live digital twin of all underground infrastructure in the nation that can be accessed by anyone needing to do a dig project in a given area. Combining information they receive from traditional digital maps that include data from asset managers and data gleaned from processes like Ground Penetrating Radar (GPR) and Electromagnetic Location (EML), best used in concert, precise data will be accessible to relevant parties who can then take the information into account to avoid potentially dangerous strikes.

The GPR and EML technology can also take away hazardous situations when it comes to the actual process of surveying. This technology, whether utilized manually, attached to a ground vehicle, or a UAV, continues to improve both in terms of its reach and weight. To the latter point, as an example, some companies, like DGT Associates, are now attaching this technology to the back of vehicles to scan what is happening under a street, the data from which can then be digitized and visualized with companies like SubTerra. That in turn takes away the need for workers to walk down an active street, or forcing work to happen in the dark at night. With safety top of mind for everyone in the construction industry, those working on subterranean projects can look to modern GIS technology to reduce that risk.

Streamlining Construction Production with Reality Capture

We all know about the infamous McKinsey report indicating that large construction projects, regardless of asset class, typically take 20 percent longer to finish than scheduled. Construction regarding underground work certainly suffers from this issue as well. To put it simply, this lack of efficiency in the industry is untenable in a world that is rapidly progressing in the other direction in most every other sector.

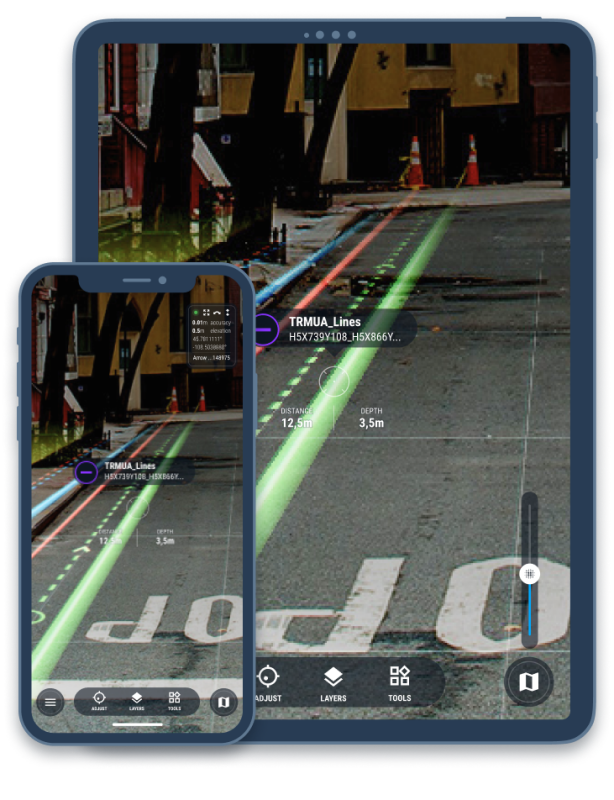

Again going back to the digital twins and maps discussed above such as the NUAR, these kinds of issues can be addressed with GIS technology. A big part of the reason any large construction project falls behind schedule is because of unknown assets being discovered underground and plans needing to shift on the fly, which often does not exactly happen at a speed which can be described as flying. However, if relevant agencies and companies contribute to a comprehensive digital twin, a contractor will be able to have a full view – sometimes with AR technology via companies like vGIS – of any infrastructure they could encounter under the surface, coming up with an efficient plan of action to which they will be able to stick.

And just as newer and improved surveying technology like GPR and EMU can be used to enhance safety, they can also streamline the surveying process substantially, especially as equipment becomes lightweight enough to be attached to vehicles, both manned and unmanned. Whereas trying to scan a particular road could take an entire day, or more, due to traffic and the realities of footspeed, being able to complete a scan using a vehicle can reduce that time to as little as an hour. Similarly, trying to locate something underwater could be a substantial effort manually, but can be streamlined significantly using a drone, which is being done by companies like Skipper NDT.

This technology also doesn’t just help as construction is taking place, but can also be utilized throughout the life of the asset and ensure maximum efficiency in keeping up with maintenance. With the advent of AI in these digital twin models, companies will be able to pinpoint the right points to perform routine maintenance. Some places, like Tokyo, have also connected these GIS systems to Twitter in order to get realtime updates and have the ability to quickly be altered to and fix leaks or other issues.

Having these exact locations can minimize damage from links as well. For example, Mumbai’s lack of accurate and up-to-date mapping has resulted in frequently-damaged pipelines, with an estimated 700 million liters of water being lost to leakage and theft. The city’s utility manager, the Brihanmumbai Municipal Corporation, launched a project in 2016 to digitally map and geo-reference all of the city’s pipelines, which is expected to reduce that water loss.

There’s no black box that will address everything leading to the extreme delays experienced in construction projects highlighted in that McKinsey report, but this technology can certainly be used to take a massive step in the right direction when it comes to delays caused by underground strikes and discoveries.

Saving Money with GIS

The other part of that aforementioned McKinsey report aside from the efficiency aspect came down to the financial side of things, with the report indicating that the average large construction project would finish up to 80 percent over budget. As with the topics above, the new methods of digital mapping and surveying can be utilized to financial ends as well.

And again, unintentional strikes play a large part in this. Although the safety ramifications of these events should and are the number one concern, there are massive financial consequences to a strike of any sort of public utility. When a pipe is mistakenly struck, one or both of the private contractor and the public municipality will have to pay the cost of the repair. In the UK, where the NUAR is working to prevent these incidents, it is estimated that these strikes have cost $1.67 billion to the national economy.

It’s not just the cost to the local economy either. Construction companies have a whole lot to lose with these strikes as well, even beyond the immediate cost of repairing a strike. That repair takes time, requiring extra man hours and extra equipment, all of which costs money. And then when you throw in the long-term damage that results from the reputational hit suffered when news of one of these strikes occurs, especially one with extreme affects to the surrounding community, companies have millions of reasons to adopt this technology.

And even if a strike doesn’t occur, these financial hits can add up even upon the discovery of an unknown asset under the surface. One of the prime examples we can point to in order to illustrate this reality is with the Sydney Light Rail project. The main line of the project was initially quoted with a price tag of $1.6 billion, but ultimately cost nearly double that with a final bill of $2.9 billion. Projects like the Big Dig in Boston and others around the world have suffered similar delays and financial spikes, largely due to substandard surveying and knowledge of assets under the surface.

Preparing for AEC’s Digital Future

There is plenty happening in the here and now to occupy our mind in the world of construction that it can be unfathomable to look to the future, but the best companies have that long-term vision to maximize their viability both now and looking forward. And in the world of underground surveying and digging, being on top of the technology discussed here is only going to help in an ever-changing world.

Part of this simply goes to trends around workers in the industry. Whereas in the past many on-the-ground workers spent entire careers working in one spot and for one company, we are seeing more and more people shift out of the industry earlier in their work lives, and projects being subcontracted out to result in new, unfamiliar faces working in specific areas. Those imprecise traditional maps from asset owners may not be as catastrophic in the hands of an experienced worker familiar with the area and the local utility companies, but in the hands of a newer worker they could lead to costly and dangerous results. This is only going to become a bigger problem in the coming years, with estimates indicating nearly half of the construction workforce will retire in the next decade.

The way localities manage their infrastructure figures to change moving forward as well, with a greater focus on underground space meaning more precise knowledge of assets and infrastructure under the surface being necessary. In places like Hong Kong and Singapore, both areas with large population density needing to take advantage of as much on-land space for its residents as possible, they are moving more of their critical infrastructure below the surface. Population centers are becoming denser all around the world, and land space is top of mind in many of these places, so a similar transition can likely be expected in other locations as well over the coming years and decades.

The companies who are most comfortable with the cutting edge surveying equipment that can both map out existing infrastructure as well as identify areas with potential geologic risk such as faults and shear zones intersecting with caverns will be able to have an advantage when this planning becomes a reality in more areas around the world, while also being able to more easily onboard new workers joining the sector in the coming years.

Since that McKinsey report was released back in 2016, the construction industry has quickly come to the realization that it is imperative to join the digital age and utilize the immense amount of cutting edge GIS technology to increase efficiency and financial viability. This is especially true for underground construction, where unintentional strikes and discoveries of assets can result in massive delays, dangerous situations, and costly damages. The solutions to mitigate all of these issues are out there and continue to improve, and the companies who take advantage will have a leg up now and in the ever-changing landscape of the world.