The “metaverse” – in which theoretically geospatial should play a role – is all the buzz in the business world right now, with some of the largest companies in the world cutting across industries making massive investments in the space, with varying results so far. Generally speaking, a large portion of that focus is in the social aspect of what many see as the next phase of the internet. However, where plenty of others see the real value coming, at least early on, is with the so-called industrial metaverse, which depending on your definition may already be here in nascent stages. Largely empowered by digital twins and the increasing amount of data that can be incorporated into them, they will allow large facilities and other enterprise spaces streamline a lot of their workflows. And so while the social aspect may get more buzz, there are plenty of companies looking to make headway on the industrial side.

Hexagon is among those companies that are at least on the periphery of this idea, specifically with their Smart Digital Reality strategy. This centers around how exactly the real world will intersect with the metaverse, “ensuring prosperity, safety, and sustainability for the planet.” The company is looking to advance their movement in this space, and this week announced a new strategic partnership with 3D digital twin firm LocLab, aimed at “empowering industries with Smart Digital Realities in their design, construction, and operation processes,” per the press release for the announcement.

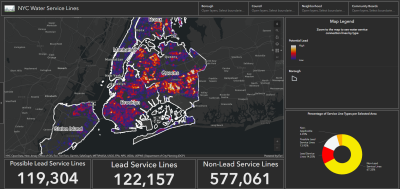

The Smart Digital Reality works on the premise that the line between physical and digital is only going to become more blurry, and ultimately will no longer be viewed as separate realities. This is, of course, also the same basic premise of the metaverse, with the idea of all physical data being available digitally with an ever-growing number of datasets and real-world factors being drawn into digital models. Hexagon has the ability to be on the forefront of this idea given their core competencies, with hardware to both complete the reality capture process necessary to create the base for these models, as well as their sensor-software systems to integrate all of that data. Their website lists five key components to making this reality, with reality capture, positioning, design and simulation, location intelligence, and autonomous technologies building that backbone.

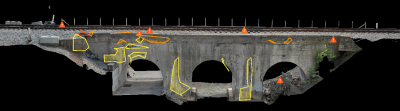

It makes sense, then, to take those core competencies from Hexagon and combine them with LocLab, who specializes in creating and managing the actual digital twins that come from the data. Their digital twins are created and distributed in their “3D Rocket Player,” which they compare to a digital piece of music in a music player, and for which there is no installation or software license needed. The player allows users to interact with their digital twin, navigating freely through the model in various settings. Among the use cases for this technology, LocLab calls out visualization, planning optimization, simulation for process optimization, facility management, training in AR and VR, and data integration.

All of this plays right into what people have conceptualized as the industrial metaverse, giving facility managers or any other stakeholder on a large project a vast amount of information from which they can make their decisions. Hexagon is looking for this partnership to accelerate the growth to that point, and combining the strengths of both companies seems like a good strategy to achieve this goal. With the data collected from Hexagon and the platform provided to house and optimally display that data with LocLab, stakeholders at large facilities will be able to simulate potential changes to their workflow based on massive amounts of data to maximize efficiency without having to rely on more traditional trial-and-error strategies. They’ll be able to train their employees on accurate models of equipment without having to shut down the floor. Potential maintenance issues can be caught by a vast array of sensors much more quickly than they would just relying on humans to find them, saving massive amounts of time and money in the process.

We’re not quite at the point where all of this is the norm in the industry, but these kinds of pushes are what gets us closer to that reality. On the partnership, Hexagon Geosystems division President Thomas Harring said, “The combination of Hexagon’s leading reality capture and software portfolio and LocLab’s automated 3D digital twin creation workflow make Digital Realities more accessible to existing and many new customers.” LocLab CEO Dr. Ilka May added, “The joint digital twin solution can be used for various applications, from public relations consultation and visualization, training applications in virtual spaces and simulation and much more.”