Sponsored by Bentley Systems

Protecting Critical Rail Infrastructure

A commercial and residential district known for its street fairs and annual Christmas Market, Toronto’s historic Distillery District is emerging as one of the city’s most successful and unique revitalizations. Contributing to this urban renewal is the 31 Parliament Street luxury condominium development, which is being constructed alongside the Union Station Rail Corridor (USRC). The new 41-story, mixed-use, energy-efficient building is strategically located next to public transit and within walking and biking distance to the waterfront, trendy lifestyle amenities, specialty shops, and lush green open spaces and parks—the epitome of convenience and sustainable living.

During construction of the building, Monir Precision Monitoring was contracted to monitor the shoring of the excavation site and the USRC railway, protecting the critical railway from displacement and service disruption. Featuring more than 6.4 kilometers of track, 14 rails, and associated switches and platforms, the USRC moves 300,000 people daily to and from the city of Toronto. Keeping the vital commuter corridor open throughout the development of 31 Parliament Street was crucial. “An instrumentation plan was developed to closely monitor displacement of the rail using a myriad of prisms being read by an automated total station, as well as monitor the excavation site,” said Samantha Ford, president at Monir.

Pushing the Boundaries of IoT Sensor Data

The building site is situated on reclaimed land. Centuries ago, the shoreline had been modified and waste dumped into the area, creating challenging conditions during excavation works. The moist soil stratigraphy, combined with the proximity of the structure to the USRC, necessitated stringent requirements and multilevel approvals to ensure structural integrity of the building foundation while avoiding impact to the railway.

“The monitoring requirements were stringent and the slopes from the track to the top of the excavation made for tricky sight lines with the automated monitoring system,” said Ford.

Previous digital monitoring solutions were not streamlined or comprehensive enough to meet these requirements or add value to the project.

“[These software applications] were also more challenging to integrate sensors with, not graphically well-represented, and did not include customizable reporting,” said Ford.

Seeking to push the boundaries of their Internet of Things (IoT) sensor data, Monir realized that they needed technology capable of leveraging their instrumentation data within a more holistic digital environment. They wanted to explore a more integrated technology solution where reality modeling, mobile mapping, and sensor data management can be combined to provide virtual context and real-time insights to make proactive decisions. To digitally simulate and visualize the excavation and construction works and their impact of on the railway, Monir needed intelligent infrastructure monitoring software that brings together data from IoT sensors and other connected devices within a single platform.

“ The Bentley software and services deployed on this project gave us

peace of mind in the results, speed of delivery, and reliability of critical

monitoring information for early detection of any issues that may arise.”

– Samantha Ford, President, Monir Precision Monitoring

iTwin IoT Provides Value-Add Opportunity

Having been a sensemetrics client since 2017, Monir initially used Bentley’s sensemetrics® for standard IoT monitoring. Introducing iTwin IoT offered digital twin capabilities for visualization of the site throughout the construction process.

“With Bentley’s new iTwin IoT software, this project presented a unique opportunity for Monir to test the value add of the digital twin module to their existing IoT monitoring processes,” said Ford.

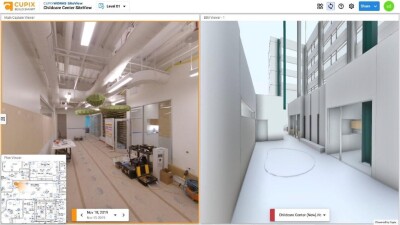

The existing sensemetrics upgrade feature facilitated seamless migration of all project monitoring data to the iTwin IoT platform and unlocked digital twin potential. Working in Bentley’s digital twin environment, Monir was also able to integrate iTwin Capture and OpenGround, which allowed reality modeling and borehole data to be viewed alongside the IoT sensor data.

Adopting the integrated digital twin solution simplified Monir’s data management and enhanced visualization of project status. Utilizing the timelapse of multiple drone flights and iTwin Capture, Monir was able to successfully monitor and digitally view how conditions were changing remotely over time.

“Once the data was processed in iTwin Capture, we associated that data into iTwin IoT,” said Ford.

The integration of the IoT sensor layout within the digital twin module allowed Monir to view their sensor data in a digital twin environment, better understand site conditions, and track alerted areas based on established thresholds they set for their on-site monitoring prisms. By taking advantage of iTwin IoT’s digital twin capacity, Monir was able to visualize their instrumentation data in full context of current and historical site conditions and against geotechnical plans.

Digital Twin Proof-of-Concept Advances IoT Monitoring

Using the iTwin IoT platform for management and visualization of instrumentation data increased Monir’s operational efficiency by upwards of 40%. The digital twin solution reduced the project timeline by six months and minimized the need for on-site excavators, dump trucks, mobile cranes, and diesel fuel, positively impacting the environment.

“The timeline of the project was anticipated to be around 5,000 work hours, and it was completed in just under 2,000 hours thanks in part to Bentley technology, saving over half the time on site, roughly 60%,” explained Ford.

Having rapid access to instrumentation calibration documents and real-time insight into project status and potential issues, Monir was able to make proactive decisions and quickly respond to client needs. Now, the client can excavate and construct faster, resulting in months and millions saved on the construction schedule.

Digital twins are relatively new in the IoT monitoring industry, and Monir showcased the benefits on the 31 Parliament Street project as a proof-of-concept. Working in a digital twin environment provided a holistic project overview, compared to the myopic view offered by the individual sensors alone, protecting the vital USRC transit infrastructure.

“Ensuring safety of the railway during construction was a significant requirement, which we were able [to achieve, and] reduce costs of our scope alone by USD 1 million, proving automated monitoring to be a viable and vital opportunity to reduce costs and provide reliable data to ensure safety of the rail,” said Ford.

Bentley’s digital twin technology allowed Monir to proactively assess their next steps throughout the entire project and ensure the safe passage of trains along the corridor, keeping a vital commuter artery open for business.

“While our usage of iTwin IoT was a proof-of-concept on this particular project, we see great potential for our clients to experience the benefits quickly,” said Ford.

Project Summary

Organization: Monir Precision Monitoring

Solution: Surveying and Monitoring

Location: Toronto, Ontario, Canada

Project Objectives:

- To avoid railway shutdown during construction of a new condominium complex.

- To integrate digital twins within IoT monitoring processes as a proof-of-concept for future projects.

Project Playbook: iTwin Capture, iTwin IoT, MicroStation, OpenGround

Fast Facts

- 31 Parliament Street is a new condominium complex being built in Toronto’s Distillery District located adjacent to the busy Union Station Rail Corridor.

- Monir was contracted to monitor shoring of the excavation and displacement of the rail during construction of the building.

- Leveraging iTwin IoT, Monir piloted digital twins within their existing monitoring workflows to visualize and assess the project site.

ROI

- Using Bentley’s digital twin platform to manage and visualize their sensor data increased operational efficiencies by 40%.

- The software helped save 3,000 hours in on-site assessments and reduced the project timeline by six months.

Want to learn more about how you can use iTwin on your projects? Come to booth 612 at Geo Week!