The mobile mapping sector has become an integral part of the larger engineering and geospatial industries. Hardware improvements have made it possible to fit more sensors on a single unit and to capture data at higher speeds. On the software side, artificial intelligence capabilities have been introduced or improved, making data analysis faster and more accessible. All of this has made the technology crucial for many projects, particularly large-scale horizontal projects such as new highways or rail projects. Today, those are generally the types of areas where these tools are used, with established roadways with regular structure, making it easy to establish ground control and keep the data accurate.

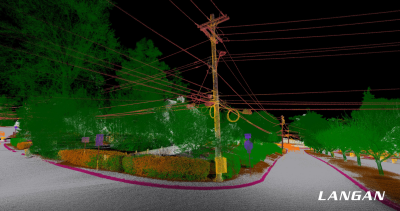

That doesn’t mean mobile mapping usage has to be limited to these kinds of structured areas, though. Recently, Geo Week News spoke with Russel Hall, a senior survey project manager with Langan, about how his team utilizes mobile mapping. Unlike most other organizations, Hall’s team at Langan is using their mobile mapping rig as much as possible, not limiting it to traditional project types, but instead using it for mapping large sites accessible by car, such as abandoned retail areas that may be ready to be renovated or rebuilt.

“We will try to leverage our mobile mapping on any site where it makes sense,” Hall told Geo Week News. “Most of our deployments are not roadways.”

Hall's team's non-traditional usage of mobile mapping comes from an attitude of wanting to take advantage of the technology as much as possible. From their perspective, they’ve purchased the rig, so they should be looking to use it as often as possible and figuring out where that line is. He said that when he gets a new piece of technology, be it hardware or software, he immediately tries to figure out its limitations and then work backwards from there. At Langan, they are looking at how often they are able to use these tools to improve their workflows, and using that information to determine the ROI from the purchase.

Hall told Geo Week News that he “had an edict to use it as much as possible,” and that ultimately, “necessity is the mother of innovation.”

There were a couple of general scenarios in which the mobile mapping rig would be used on projects by Hall’s team, away from the typical roadway projects. One is for a simple Alta survey, say for a franchisee who needs updated maps of their properties. Additionally, they will collect this data for engineers who are working on a renovation or rebuild in an area and need an accurate assessment of the site’s existing conditions.

For both of these, Hall has worked to create an efficient workflow to quickly capture this data using a mobile mapping rig, allowing for the projects to be completed more quickly, the rig being able to move to a new job site, and ultimately completing more projects and creating more revenue for the team. He also added that where mobile mapping isn’t able to capture everything perfectly, they will go out and “infill” the data with SLAM scanners or, where necessary, drone-based lidar.

As one would imagine, perhaps the biggest issue to solve in order to put these workflows into action is to ensure proper control around a site. Since the biggest advantage of using these rigs on this kind of project is efficiency, it would essentially defeat the purpose if the survey crews had to go out and spend a whole day setting up control points all around a job site. What Hall wants is to be able to go in and out with the minimum possible number of points, something he played around with for a year to establish the best practices.

Today, they are generally able to mission-plan ahead of getting to the job site, allowing for the crews to quickly start their scanning. He said there are people on his teams who can go out and set the controls on the fly, but he noted that it’s mostly those who also have worked on the registration side and have seen the process work end-to-end.

“That’s the only way you can get better at scanning,” he explained. “In general, it’s any of them who have gone through the whole process, because they get to see, Oh, if I had spent an extra five minutes in the field doing this one thing, it would have saved me three hours in the office. You don’t get that full picture unless you do all of it.”

For this process of setting up controls, Hall explained that the most important factor to remember is the accuracy clients need for their deliverables. When taking a job, he says that the first two questions he’ll always ask are the intention for the client and the accuracy they need. While the newest scanners on the market today, like the Leica TRK that Langan uses or any of the other models, can produce extremely high accuracies, that’s not always required for the project at hand. If the client doesn’t need quarter-inch accuracy, then there’s no sense in spending the extra time to ensure that extraneous accuracy.

“I think this is where a lot of surveyors go wrong.” Hall said, “Just because they can make it a quarter-inch [accurate], if the person isn’t asking for that, then you’re wasting your time. You’re wasting money. The biggest thing up front is understanding what the deliverable is, the accuracy requirements, and then figuring out how to efficiently work our way back to that.”

The other piece that Hall’s teams need to account for is the site itself. While he has created a guideline process for setting up these control points, it’s still dependent on the project. As noted, part of that is the accuracy required by the client, but also the physical location of the site.

“Every site is different. If they’re all wide open sky, then yes, it would all be standard,” Hall explained. “But a lot of these sites have either urban canyon or tree coverage, so you’ve got to tighten up a little bit and look at where you intersect. So there are variables to it.”

Today, Hall’s teams have worked this system to the point where they can almost use it as an assembly line process – Hall himself compared it to Ford’s systems – where the survey crews can go to a site, complete the scan, and then get right out and on to the next one. He says that while most of the organization had little awareness of what they were doing a few years ago, today, engineers will be asking for scans on a number of their projects.

We asked Hall what advice he would give to other surveyors who want to start expanding their mobile mapping usage to improve their efficiencies, and he said it’s all about finding those sweet spots.

“Get rid of the extraneous,” he said. “And in terms of control, you’ve got to find the sweet spot to get exactly what you need to achieve. If you end up throwing down, say, 16 points, you’re going to have a field crew just locating control all day,” and giving back any of that efficiency you would have gained. So while there is some work on the front-end to establish those procedures, the efficiency gains on the back end, at least for Hall’s team, have proven to be well worth it.