Sponsored by Cintoo

For today’s renovation or new construction projects, working with digital twins – or at least an accurate 3D model – is becoming more and more common. Scanning technology is becoming both more powerful and easier to work with, and more importantly, the software used to process scan data and create and interact with those models has rapidly improved over the last few years. Now we’re at a point where working with these models is a requirement for projects, a development that has gone a long way towards improving efficiencies, avoiding rework, and ultimately staying closer to budget.

One of the issues that can arise with these kinds of workflows, however, is jumping too far ahead too early, centering the project around the model. Instead, the most successful projects are going to plan out the entire process before starting in a method that Cintoo refers to as a “scan-first” approach, something they say will ultimately lead to a higher ROI as opposed to immediately trying to build a model-based twin.

In their words: “In a model-first approach, teams labor over drawings and idealized CAD, only to discover major discrepancies and inconsistencies with the real-world environment later. In contrast, scan-first immediately captures as-built reality, creating an accurate baseline.”

In order to really succeed with this kind of approach, there are a couple of key steps to take before even starting to work within the software to build and interact with your digital twin. The first step, which seems very simple but is skipped or rushed through quite often, is really thinking about the purpose of a project. Cintoo recommends a few key questions to ask before even getting started with a scan workflow.

It starts with defining the purpose of the project and outlining how exactly the data will be used. Which stakeholders on the project are going to be using the data? What is the ultimate goal for this project? Starting with that question lets one plan out the rest of the project with the end in mind, rather than hoping your data eventually fits your needs. From there, it’s about planning a lot of the actual scanning processes. Which areas of a project site need to be scanned, and are there any constraints to reaching said areas? Do any control systems need to be set up to reach the accuracy required for the project? Who will need the data later, how will it be shared, and how can we structure our data to minimize friction when sharing this data?

All of these questions should seem fairly basic for this kind of project, but it’s important to really think about and plan your scanning around these questions rather than just assuming you’ll be able to answer the questions as these steps come up. It may be true that the project can be shifted to meet needs as they come up, but that’s only going to add time and money to the project that could’ve been saved with better planning on the front end.

After answering those initial questions, project managers should start to have a better idea of how to approach the scanning portion of the project as efficiently and effectively as possible. In figuring out exactly how to scan a space, it’s important to physically visit the site to have a good idea of the best equipment to use and how to set up controls, if necessary. By this point, the required accuracy for the use of this model should already be understood, meaning there should be some idea if SLAM-based scanners or drones will suffice, or if terrestrial scanners will be required. Visiting the site will add further context to the plan for scanning, getting a good understanding of where to set up scans if a tripod-based scanner is necessary, or where to set any controls to maximize efficiency and quality for the data. All of this should be happening before any scanning takes place, and will ensure the data collection process goes as smoothly as possible, and the data is ultimately maximized by all of the parties involved.

After all of that data is collected, the model comes into play, and software like Cintoo’s is utilized. There are a couple of key advantages that Cintoo can offer for these model- and digital twin-based projects, including the fact that it is hardware-agnostic. Because many of these projects are so complex, there are often different types of scanners used for a single site. With Cintoo, there’s one less worry involved with this process because the software will work well with the data from any scanner.

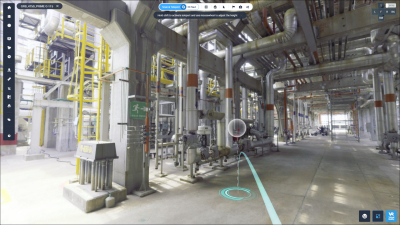

Additionally, Cintoo is a cloud-based platform, something that has made a major difference for these types of projects. For one thing, firms are not required to have the data storing capabilities to store massive amounts of data on-prem, instead saving everything into the cloud. Along with advantages for storing data, this kind of cloud-native platform enables significantly better collaboration processes. Rather than needing to mail hard drives around the country – or the world – stakeholders can all access an updated, visual source of truth at any time of the day.

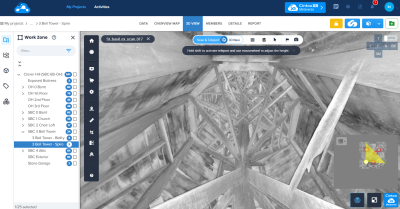

Finally, Cintoo can integrate with BIM and GIS in real time, a major capability for many of today’s projects. The company shares one example of a customer taking advantage of these integrations, sharing how General Motors used Cintoo to build a cloud-based digital twin of its global facilities. These include over 40 million square feet of plant space that can be accessed by team members around the world, virtually, to run measurements or clash checks. Their reality-capture lead, John Brown, said this ability to stream scans at the same resolution as the source scanning, giving team members “an immersive experience akin to Google Street View.”

One of the best examples of this workflows is one of Cintoo’s customers, iSCANO. Working on a project St. Basil’s Church in downtown Toronto, the organization partnered with Cintoo to deliver high-quality scan data to their client. This was a challenge both because the for original as-built documentation was either missing or incomplete, with historical changes to the structure undocumented. What was available was scattered across various paper archives, and the structure itself was complex with concealed spaces that had not been documented. All of this meant that planning scans were vital amid questions around scope, budgeting, and decision-making.

To deliver the results through all of these potential issues, the team utilized the scan-first approach, with a modular scanning strategy. Over the course of less than a week, they completed over 500 high-quality terrestrial scans, including hard-to-reach areas and spaces that had not previously been documented, and filled in some areas with SLAM scans, with the entire dataset coming in at 3.5-4 mm resolution. Ultimately, they were able to maintain full control of the scan data using Cintoo, and rather than converting everything to BIM all at once they did so modularly based on project need.

"I think a lot of times when surveyors or reality capture specialists are looking at this, looking at this; we're trying to just do our service and walk away and not seek a little bit more of a value behind the scanning,” said Sebastian Graterol, Founder & Director of iSCANO. “A lot of times people are just looking for the as-built drawings. For St. Basil's, we weren't just looking at the scan-to-BIM process as the only hand-off, and then that's it. The moment we were able to use an ecosystem or platform; it allowed us to do a little bit more with tools that went beyond the scan deliverable."

Taken all together, Cintoo’s recommended scan-first approach and cloud-based platform offer a more efficient entry point into the world of digital twins. Rather than starting with an idealized version of a space and adjusting when reality intrudes, this approach allows teams to make smarter decisions from the outset. As digital twins become less of a novelty and more of an expectation in AEC and manufacturing workflows, success will hinge not just on having the right tools but on knowing how and when to use them.

Learn more with a demo hosted by the Cintoo Success team.