by Nathan Savory, Leica Geosystems

The King Fahd Sports City Stadium has stood on the outskirts of Riyadh since 1987 and remains one of the region’s most iconic sports venues. With a roof spanning 47,000 square meters, the structure, supported by 24 towering pylons, mimics the shape of a traditional Bedouin tent.

As hosts of the 2034 FIFA World Cup final, Saudi Arabia’s Ministry of Sport were aiming to renovate the stadium to boost its capacity from around 60,000 to 80,000 seats, while also modernising its traditional design. However, the only existing architectural records were hand-drawn plans from the 1980s – insufficient for today’s era of digital construction. To support the transformation, the entire stadium had to be precisely scanned and digitally documented.

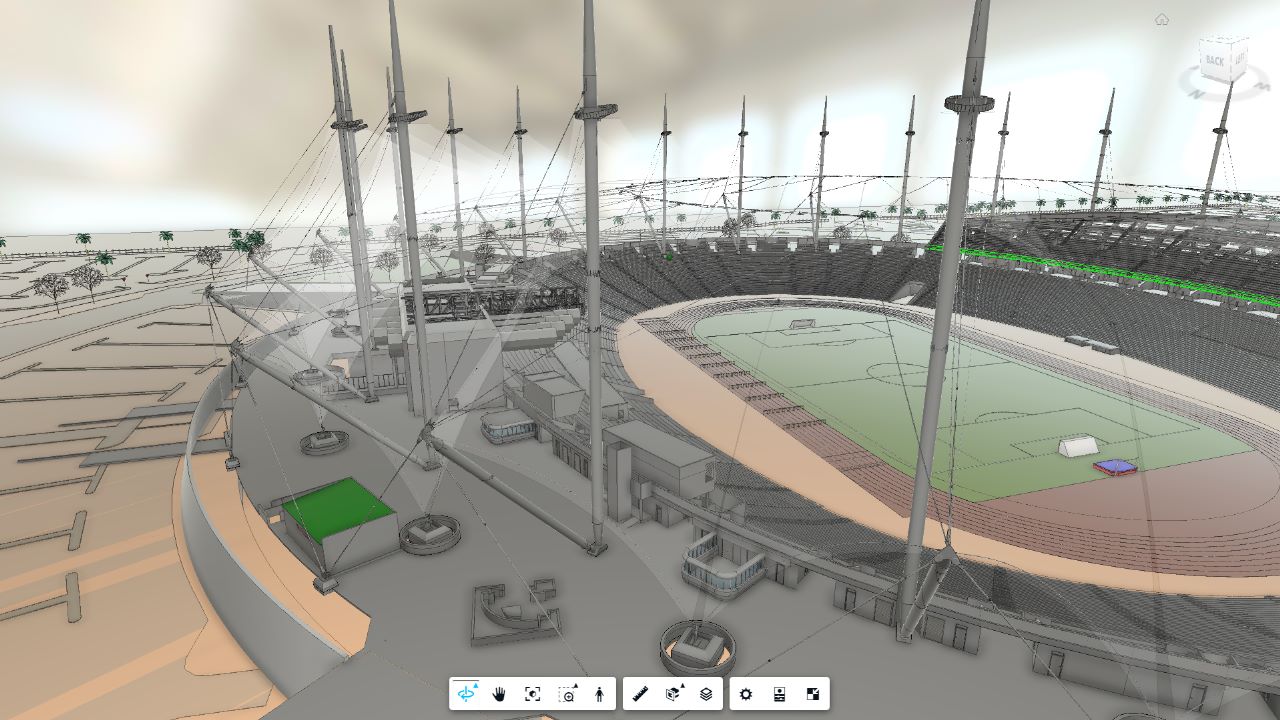

Tasked with bringing the stadium into the digital age, BIM solutions provider Inisys, created a highly accurate 3D model of the stadium. Despite numerous challenges along the way, the final model met the tight specifications set by the engineering and architectural teams, demonstrating the importance of high-quality surveying work and reliable data in complex renovations.

A Stadium-Sized Challenge

Surveying a structure as vast and multifaceted as the King Fahd Stadium presented unique challenges. With outdated drawings as the only official reference, the survey team had to work from a limited understanding of the stadium’s evolving layout, which complicated early planning.

Both the architects and the engineers required extremely tight tolerances for dimensional data from Inisys. To meet these demands, the BIM model had to comply with ISO 19650 standards and deliver exceptional accuracy.

For example, all the anchor points for the canopy had to be precisely geolocated, and many of them from a long distance: the structural joints had to be modeled within a 6 millimeter tolerance, while the architectural elements had to be modeled within a 25 millimeter tolerance. The team couldn’t use a drone due to restrictions from the neighboring air force base. This forced the team to use terrestrial scanners, which had the range and accuracy necessary to complete the job to the required levels of precision.

The stadium’s interior proved to be just as complex, including five levels of offices, with underground VIP suites, densely packed MEP, gymnasiums, and changing rooms. With operations and maintenance staff living in many of the rooms, accessing these spaces was its own challenge.

Besides the complexity of scanning the structure itself, the project had to be planned and managed around events like football matches, which often resulted in site closures for several days. So, besides constant collaboration with architects and engineers, the project also required close coordination with the facility manager.

Scanning Every Corner of the Stadium

To meet the demands of the project, the surveying team carried out 4,700 laser scans over five weeks using a combination of Leica ScanStation P20 and Leica RTC360 3D laser scanners. A total Station was also used to geolocate over 200 control points.

Laser scanners captured various survey points at the edge of the main mast, as well as the pylons supporting the stadium’s tent-like roof.

The Leica P20 was used to acquire high-resolution scans at distances over 50 metres to capture details at the top of the roof from ground level, since the team couldn’t use drones.

Halfway through the project, the scope expanded to include detailed scans of the mechanical, electrical, and plumbing (MEP) systems. So, the team had to capture HVAC ducting, fire hydrants, and cable trays hidden in ceiling spaces. This involved using portable scaffolding to access roof areas, removing ceiling panels, and then placing the RTC360 inside tight spaces.

Once the interior scanning was complete, the team moved to creating a topography scan of the area surrounding the stadium, including parking facilities and vegetation.

“We managed to scan the entire exterior in just five days. The laser scanners meant we could move fast without sacrificing accuracy, which had a big impact on both our timeline and the overall project budget,” said Bill Rice, Managing Director at Inisys International. “Even the surveyors at one of the contractors were amazed by how quickly we were able to scan everything outside and build the model.”

To ensure accuracy and alignment in the point cloud, the team relied on a suite of advanced software. On-site data was captured and registered in the field, with further processing and point cloud registration completed back in the office. The outputs were exported to BIM-ready formats. To then unify the data, point cloud processing software was used to align the survey coordinates with the correct georeferenced coordinates from the surveyors on site, ensuring spatial accuracy from the outset.

“We also utilise the reporting tool within the registration software as a part of our quality management process,” said Rice. “The combination of these tools helped us deliver a BIM model that met the tight tolerances and high standards required.”

A BIM model fit for FIFA

The result was a detailed BIM model that is now actively used by the project’s architectural and engineering team, helping them design and implement the stadium’s upcoming renovation. The model provided a live platform where stakeholders could track progress, review updates, and download deliverables as needed. This enabled transparent and real-time decision-making throughout the entire design process.

Beyond serving the architects, the model proved invaluable to the wider engineering team. “The engineers were honestly shocked we could deliver a BIM model with that level of detail,” said Rice. “They were actually able to run stress calculations directly from the model, saving them days and days of additional work. The impact went well beyond just the design phase. Everyone had access to the model and could compare it against their own inputs from day one, maintaining consistency and quality across the full workflow.”

The BIM model stands as a benchmark for how precise data, shared platforms, and expert execution can come together to transform stadium redevelopment across the region. The success of the project has already led to new opportunities for Inisys, including follow-on work at the Prince Mohammed bin Fahd Stadium in Dammam, Saudi Arabia.

“We had to work around some big challenges: outdated drawings, tight timelines, and the need for really high-resolution detail in certain areas,” Rice pointed out. “We were able to deliver accurate, accessible data that fed into everything – from stress analysis to design coordination. It really shows how quality capture and strong collaboration can simplify everyone’s work downstream."

Nathan Savory is the Regional Segment Manager- Reality Capture (EM, EMEA & Asia) for Leica Geosystems