Since GeoSLAM released the world’s first handheld SLAM scanner eight years ago, 3D laser scanning has gone from strength to strength. As scanning instruments have become more lightweight, robust, versatile, and affordable, the appetite for mobile laser scanning has greatly increased. Though traditionally used by surveying companies, we now see scanners being used across a vast array of industries such as construction, mining, forestry and many more. With a large increase in both the volume of data and frequency of capture alongside the technological advancements, GeoSLAM recognised that there was a need to speed up the time needed to process datasets, especially by those customers using fleets of ZEB scanners daily as part of their core business activities.

3D Process Automation

Though laser scanning has now reached a point where hardware is accessible and easy to use with limited training, the speed and effort required to process the collected data can still be a challenge. Breaking down large amounts of 3D point cloud data to generate something actionable can often be a sticking point, with many processes being manual and slow. Hardware has advanced in leaps and bounds in recent years, but software is often playing catch-up.

GeoSLAM understands that users want to generate clear and useful data quickly, and introducing automation is a leap in being able to get to the information beyond a point cloud, faster. The easier and more intuitive the whole process is for the end user, the more likely they are to use it. Over the past year, software engineers at GeoSLAM have been working to take the idea of 3D process automation and make it a reality, thus GeoSLAM Connect was born.

GeoSLAM Connect

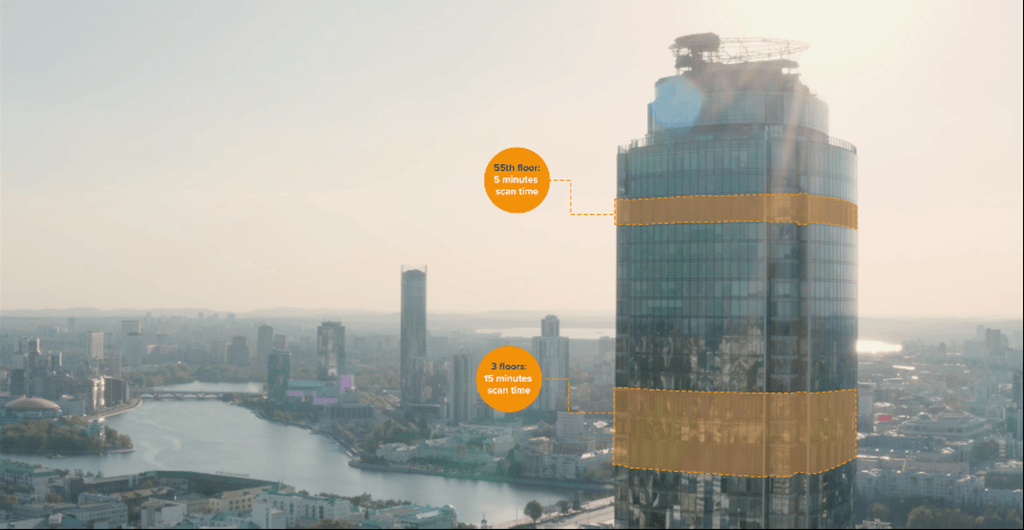

GeoSLAM Connect is a software platform for automated post scan processing. It has been developed on LiDAR OS, GeoSLAM’s new software operating system and uses script-based workflows to process your data how you want it. A simple solution to handling large numbers of scans with the versatility to resolve industry specific problems, with a range of add-on modules.

Compatible with the ZEB family of SLAM hardware, once the data is synced with Connect, a fully automated workflow will run to produce a 3D point cloud and apply any additional processing steps such as decimation, filtering and colourisation to the data. In addition, photos and notes captured using the new GeoSLAM phone app will also be positioned inside the point cloud to provide additional data to help interpret the point cloud and provide additional context and information for those using or viewing the data.

SLAM

GeoSLAM Connect provides full automation of SLAM data processing from all ZEB scanners. Commonly used data export options are stored as default workflows to simplify creating point clouds from .geoslam files. The user can also import multiple .geoslam files that are processed sequentially. Learn more about what makes GeoSLAMs SLAM algorithm unique (and why thousands of businesses have integrated it into their companies) here.

3D Viewer

The Connect 3D viewer enables the user to create and manage projects, select the default processing workflow, create reports, and visualise data. SLAM results generated from automated workflows are viewable in the 3D viewer for easy visualisation and interpretation.

Watcher Folder

In addition to the 3D viewer, GeoSLAM Connect workflows can be configured to automatically run when new data arrives in a watcher folder. The watcher folder and workflow can be defined by the user. The workflow will run on any new data arriving in the watcher folder without any user interaction with the GeoSLAM Connect software.

Solving industry-specific problems

Connect is a flexible software platform to automatically process your GeoSLAM data available with add-on modules designed to make industry specific problems, easier to solve with SLAM.

GeoSLAM Construction Progress | Smart Progress Tracking

Construction Progress allows construction companies to scan their sites and automatically compare to a BIM model or previous scan, providing stakeholders with a percentage of completion figure for their project. Construction Progress will also show clear visualisations of the changes made since the previous scan.

With construction companies tied to deadlines and with delays costing huge sums of money, a way to smartly track progress is hugely beneficial. With the simplicity of both GeoSLAMs hardware and software, scans can be conducted on site, any time and by any staff member – the data is quickly produced and completely owned by the company conducting the scan.

GeoSLAM Floorplans | Understanding Buildings

Each year billions of dollars are lost to the undervaluation of real estate globally. Quickly and easily capture up to date information on buildings whatever the size or access with handheld SLAM, and the ease of repeatability means you can keep up to date digital records.

Floorplans makes it easy to understand building layouts and sizing with the automatic creation of 2D floorplan images. By scanning a building and using Connect, you can automatically have precise 2D floor plans in a matter of minutes.

A GeoSLAM customer trialling Floorplans said that they discovered 240,000 additional square foot in a 12 million square foot portfolio, using GeoSLAM, unlocking millions of dollars of unrealized revenue.

Looking forward

The flexibility of Connect as a platform means whilst construction progress and automatic floor plan creation are first releases, there are many future solutions in active development, all based around utilising SLAM to solve real world challenges – watch this space.

About the Author: Neil Slatcher is the Chief Product Officer at GeoSLAM. He solves real world problems with SLAM and leads GeoSLAMs product team, having spent many years inventing with LiDAR technology.