Four in ten major U.S. roads are rated below good condition, and nearly half of the nation’s bridges are classified as only fair or worse. As infrastructure ages under increasing load and environmental stress, inspection shifts from a periodic validation activity to a recurring operational requirement.

Assets must now be inspected more frequently, documented more rigorously, and compared across time. Inspection teams are expected to produce defensible records that support engineering decisions, regulatory review, and long-term asset planning. The result is not just more complex inspections, but more inspections overall, and a rapidly growing volume of data organizations must capture, manage, and stand behind over years, not projects.

This growth in inspection demand is colliding with a fixed constraint: human capacity. The challenge is scaling inspection frequency while maintaining consistency, safety, and data quality across large asset portfolios.

When Digital Capture Becomes the Baseline

Over the past decade, engineering firms, utilities, and transportation agencies have adopted drones to move inspection and mapping away from manual, site-bound methods toward digital, spatially accurate datasets. Photogrammetry-based 3D models, point clouds, and orthomosaics are now standard inputs for inspection, measurement, and documentation.

Drone-based inspection is no longer novel. What remains difficult is scale: producing data repeatedly, safely, consistently, and at the cadence aging assets demand. Today, the core question is no longer whether data can be captured, but whether inspection programs can produce comparable datasets year after year, allowing engineers to distinguish real asset change from variation introduced during data collection.

Data Integrity Starts at Acquisition

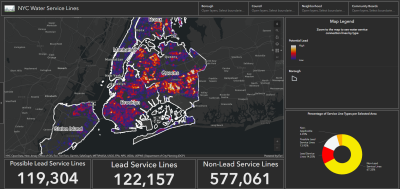

As inspection programs mature, expectations change. Digital outputs support spatial analysis, change detection, and long-term asset planning, which requires data to align consistently across inspection cycles.

That consistency must be established at capture.

Variations in ground sampling distance (GSD), coverage, or overlap can make comparisons unreliable. In many cases, the limiting factor is not operator skill or analysis software capability, but the ability to enforce consistent capture conditions at scale.

This challenge is amplified in real-world infrastructure environments. GPS availability is often limited or unreliable around large structures. Assets are vertical, complex, and spatially constrained. Inspections must be repeated often under tight safety and time constraints. Under these conditions, manually flown inspections place a heavy burden on individual operators to reproduce capture parameters precisely. Over time, variability accumulates.

A Practical Shift: Standardizing Capture for Complex Infrastructure

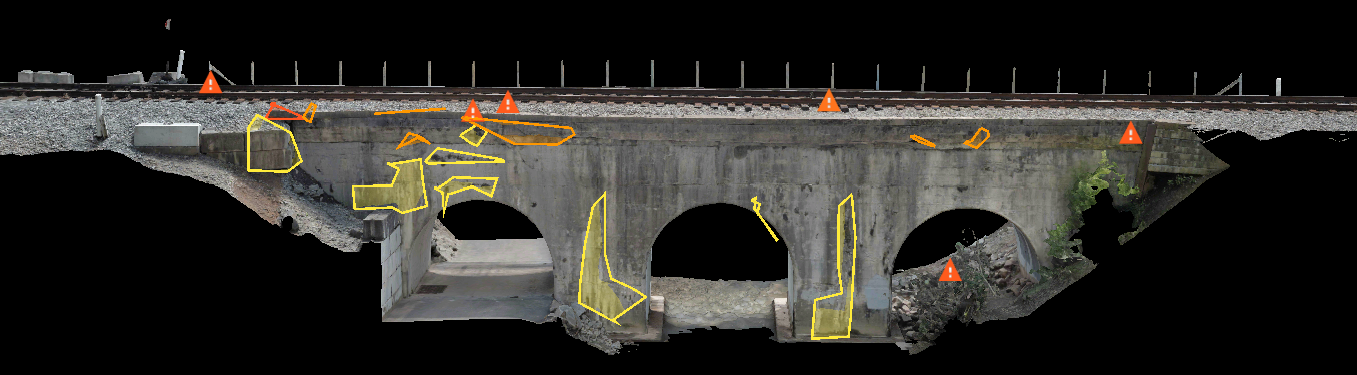

These dynamics were evident in the infrastructure inspection projects led by Stantec with gNext and Skydio on large utility and transportation assets. The goal was to produce repeatable 3D inspection datasets suitable for analysis across inspection cycles.

The workflow evolved from reliable digital capture to standardized, autonomous photogrammetry that locks in requirements like target GSD, overlap, and coverage even in GNSS‑limited areas. Autonomous capture enforced those parameters regardless of site complexity or schedule pressure, enabling consistent 3D models that align over time and support comparison, analytics, and decision‑making.

Autonomy as a Capacity Multiplier

As inspection frequency increases across large asset portfolios, reliance on manual execution, even by highly skilled teams, becomes increasingly difficult to sustain. The problem shifts from performance to capacity.

In this context, autonomous flight is not about convenience; it is about control:

- Repeatability by design: Missions fly to defined requirements (GSD, overlap, coverage, asset extent) rather than ad‑hoc piloting choices.

- Operational focus: Crews concentrate on safety and environment while the system handles flight mechanics.

- Confidence in complex spaces: Robust navigation and obstacle avoidance improve coverage around infrastructure, including areas that are difficult or unsafe to access on foot.

- Better downstream workflows: Predictable inputs make photogrammetry outputs easier to integrate into GIS, digital twins, and asset management systems, making change detection meaningful.

Remote, docked operations further extend capacity by enabling scheduled and on‑demand missions without personnel on site.

From Missions to Institutional Reliability

The next phase of infrastructure inspection will be defined by an organization’s ability to maintain digital data integrity across time, assets, and real‑world constraints. Leading programs are shifting from individual mission success to institutional reliability: comparable, defensible datasets year after year, independent of operator or location.

Autonomous, photogrammetry‑driven acquisition is emerging as a core capability for meeting that challenge, not because it’s novel, but because it matches the reality of aging infrastructure, constrained resources, and the need to scale inspection without scaling risk.

The question is no longer how to capture once, but how to capture reliably, safely, and consistently enough to trust the record over years, not flights.

About the author:

About the author:

Nikoleta Guetcheva is a Product Marketing Director at Skydio, focused on inspection and mapping workflows for infrastructure and construction. She has ten years of experience in geospatial technology and photogrammetry and is based in San Francisco, California.