VisualLive, makers of the HoloLive and MobiLive mixed reality applications for AEC, have announced a breakthrough cloud-backed feature that accelerates the anchoring process and eliminates drift. This anchoring technology could be game-changing for collaborative environments, where multiple workers need to have the same, accurate view of a particular model in a shared AR environment.

The Microsoft HoloLens (and its second generation HoloLens 2) has been the darling augmented/mixed reality product focused on enterprise – most often applied in manufacturing and industry, but also branching out into partnerships in the architecture, engineering and construction space. VisualLive, a mixed reality solutions platform that uses the HoloLens within the global construction industry, was launched in with the aim of improving construction workflows. If augmented reality could be used to break down the barriers between the office and the construction site, there was the potential for enormous ROI.

In 2017, VisualLive became the first to develop and market a mixed reality solution for the AEC industry, when they released HoloLive for augmented reality devices such as the Hololens, becoming a Microsoft Partner. Since then, their technology has been adapted to work on additional devices (including mobile Android and iOS devices) and have been integrated with BIM360 and Procore’s cloud-based solutions. Today, VisualLive reports over 1500 customers are utilizing their solutions (either via the Hololens 2 or through mobile devices).

In their latest update, VisualLive has introduced what is calling an “anchor-lock” feature that uses Microsoft Azure Spatial Anchors to save alignment points created in the field.

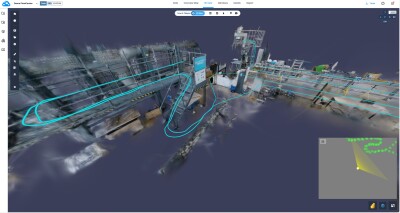

VisualLive’s anchor-lock technology prevents drifting and misalignment. Anchor-locks eliminate the need to have multi-markers by memorizing position, rotation, XYZ and all data necessary to place a model. The user is provided with the option to place an unlimited number of anchors, which can further secure a model. Once an anchor has been created, it is saved onto the loaded model for later use and anchors can be viewed online through a web portal.

When re-entering the job site, VisualLive can automatically detect position based on the surrounding area, and places the mode in accordance to its anchor position. Devices use automatic space detection with the anchor-locks to create comprehensive visuals which are “memorized” cross-platform and can be activated for multiple users. As soon as a user walks near a lock, it will activate and snap a placed model into alignment.

The more of these virtual anchors are deployed in the field, the more accurate the model position will be. Because the anchors are stored on the cloud, it is straightforward to share them with others on a project, making re-alignment and re-anchoring unnecessary from person to person.

The innovation of the anchor-locks has brought precision to models across devices, which has led to saving field users time and increasing team collaboration.

In a Microsoft Customer Story (read the entire case study here) featuring VisualLive and NOX Innovations, Brian Pemberton, Director of VDC at NOX Innovations says that that using the HoloLens and VisualLive has had an immediate ROI for his work.

“The ROI on using HoloLens and VisualLive becomes apparent very quickly. We’ve seen a 21% increase in productivity goals; an 84% increase in change order approvals; a 14 percent reduction in fabrication errors making it to the field; and a 16% reduction in safety incidents because HoloLens lets the team see more of the installment area.”