Varjo, a developer of VR/XR computing devices for the enterprise, is introducing two new features to the XR-1 Developer Edition headset. Real-time chroma keying and marker tracking allow enterprise customers to seamlessly integrate virtual and real worlds, interact with photorealistic virtual content as they would in real life, and achieve pixel perfect accuracy and occlusion inside mixed reality.

Known as ‘green-screening’ and used in broadcasting and film, chroma keying aligns virtual content accurately with the physical world. This allows users to easily define parts of reality, identify them with color and replace them with virtual models or scenery without heavy development costs. With chroma key, real objects and hands are always visible allowing intuitive interactions.

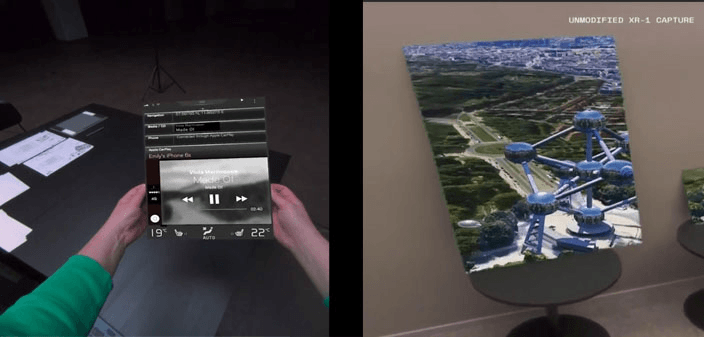

Varjo’s new object tracking with visual markers feature makes it easier to place virtual objects on the surroundings. A simple piece of paper with visual markers can turn into a virtual world, or a virtual screen as demonstrated in the picture below.

Together, the XR-1’s new features open up new possibilities for various applications. For example, pilots can sit in a replica of a plane or helicopter cockpit with real controllers and immerse themselves in a virtual world for realistic training. Designers can collaborate in an immersive mixed reality space, interacting with virtual models and making changes to them in real-time, or virtually ‘dress’ 3D prints to look like material-finished products. Researchers can conduct studies inside life-like mixed reality, simultaneously combining virtual and real-world elements into the research environment. The subjects can hold virtual products or instruments in their hands and interact with them.

“It depends on the use case,” Urho Konttori, Varjo’s Chief Product Officer, told SPAR 3D when asked about chroma keying’s reduction of development costs.

“Think of it this way: it enables pixel accurate mixing of the real-world cockpit and virtual world around it. This means that pilots get to operate the plane exactly as in the real world, learning the muscle memory, because the whole cockpit is real. You use your actual hands. But everything outside is generated as VR signal. This system is small, compact and lets you get rid of a laser projector dome, which is big and expensive. Savings are in the millions. On a single system. More importantly, you can have many more systems in the same space. More training, better training, better pilots. In the automotive space, our customer Volvo can now do things in a day that used to take weeks or longer, so the cost-savings are tremendous.”

Founded in 2016, Varjo is constantly innovating on new things, and hiring more talent. The last couple of years show how busy and focused the company is: in late 2018, the company landed a $31 million series B; in early 2019, introduced the VR-1 with human-eye resolution; and later that year, announced the VR-2 and VR-2 Pro, as well as the XR-1 Developer Edition and Varjo Workspace.

“We went directly to the end game of the resolution and have been focusing on other factors since,” Konttori said.

“It’s not like the whole XR space is a solved problem, plenty of work remains. Since VR-1, we improved the displays and optics tremendously for VR-2 and VR-2 Pro, and added the mixed reality and our dimensional 2D/3D interface Varjo Workspace with XR-1. Now we have been introducing some of the customer requested features like chroma key and marker tracking.”

Varjo’s technology is changing the way different companies operate. The XR-1 enables Volvo Cars to iterate design and UX concepts quickly and to avoid tedious tool and software changes, saving a significant amount of money along the way. FlightSafety International, a professional aviation training company, and Bohemia Interactive Simulations, a developer of simulation training solutions for defense and civilian organizations, are already using the XR-1 to train pilots. At the Loviisa nuclear power plant in Finland, Varjo’s technology is helping to minimize human errors.

Later in 2020, Varjo will share more about new developments of Varjo Workspace, and is especially looking forward to expanding to new regions and industries.

In the future, Konttori expects to see a “reduction of business travel enabled by incredibly powerful XR collaboration. I believe collaborative XR has the potential to make the biggest impact on the way we work, but it needs huge advances in devices, as well as software tools.”