XenomatiX creates advanced vision solutions for autonomous vehicles based on true solid state lidar sensing technology. XenomatiX’ sensors detect and measure people and objects’ position, size and shape, as well as distance and motion ahead of and around a vehicle in any weather and light conditions. XenomatiX’ portfolio of true solid state lidar sensors includes XenoLidar, a high resolution and long-range sensor, ideal for detection applications for L3 to L5 like traffic jams and highway navigation, and XenoTrack, a high precision short-range lidar, perfect for road quality assessment and road surface measurements on-and-off-road.

Validating Siemens’ physics-based lidar simulation model

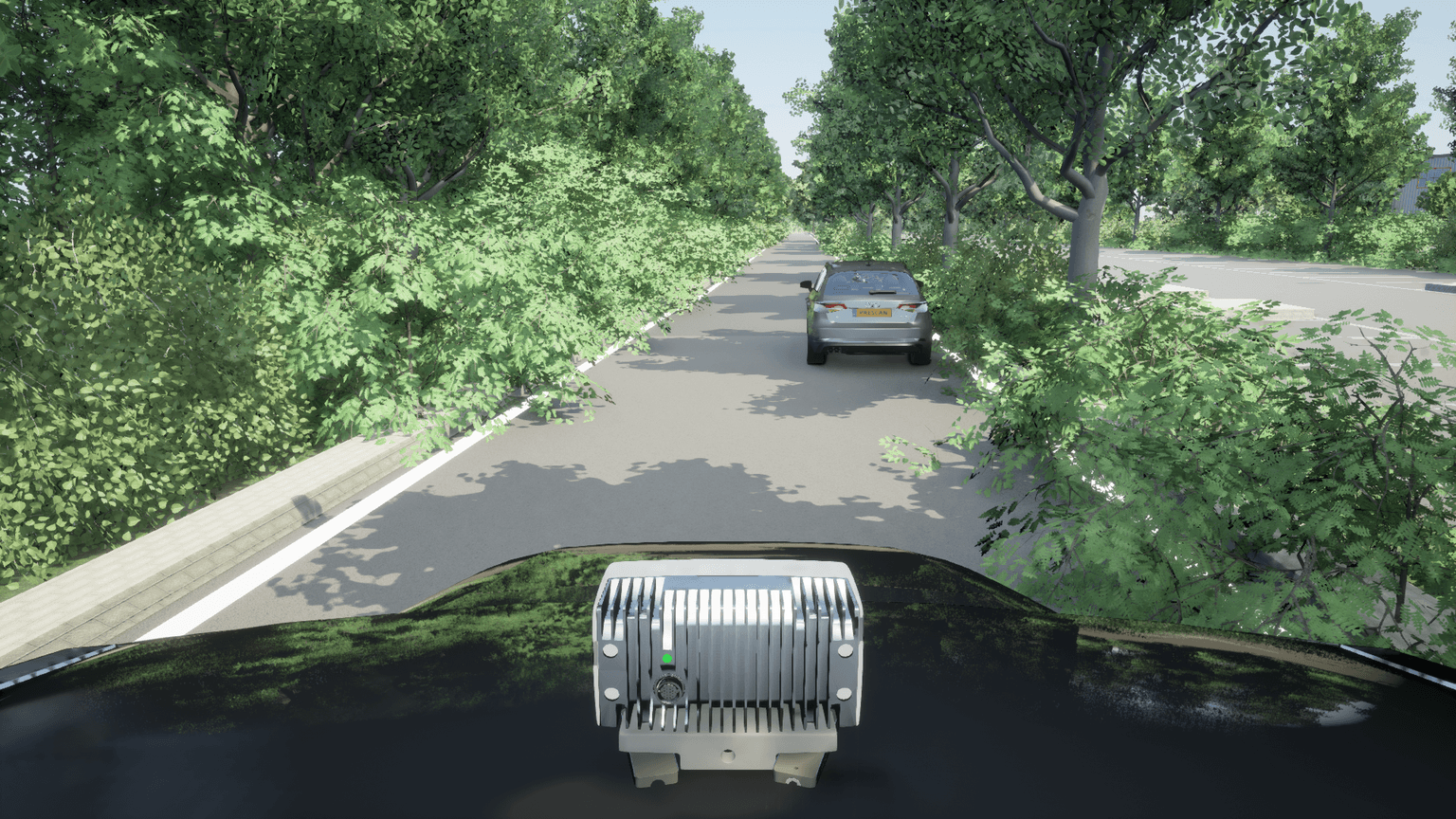

Siemens has used XenomatiX’ true solid-state lidar to validate its physics-based lidar simulation model. The Siemens Physics Based Lidar has been validated by comparing the simulator’s behavior with the behavior of XenomatiX’ physical XenoLidar unit in multiple circumstances. Without such validations, a simulation is useless for virtual design and prototyping because you cannot be sure the result represents the real world. By validating the physics-based lidar simulation model, customers know they can build on the solution of Siemens for development of XenomatiX-based ADAS and AD solutions.

Siemens has used XenomatiX’ true solid-state lidar to validate its physics-based lidar simulation model. The Siemens Physics Based Lidar has been validated by comparing the simulator’s behavior with the behavior of XenomatiX’ physical XenoLidar unit in multiple circumstances. Without such validations, a simulation is useless for virtual design and prototyping because you cannot be sure the result represents the real world. By validating the physics-based lidar simulation model, customers know they can build on the solution of Siemens for development of XenomatiX-based ADAS and AD solutions.

XenoLidar is built on a unique concept recognized by Siemens, as well as many of their customers and Tier Is. XenomatiX is also one of the first Lidar suppliers to implement a true solid-state unit that will make it to production vehicles, which gave Siemens confidence in their choice to validate the simulation using the XenoLidar product.

How the simulation model was validated using XenomatiX lidar technology and expertise

The physics-based lidar model in Siemens’ simulation package, Simcenter Prescan, was built on in-house Siemens knowledge. In the partnership project, XenomatiX added the lidar design and test experience from the XenomatiX team, who are specialized and fully focused on lidar technology, to make a first validation of the model. The combination of the optical knowledge and experience created further insights for Siemens on lidar and for XenomatiX on simulation technologies.

Next, multiple measurement tests, both indoor and outdoor, were performed on a multitude of objects, including objects with lab-measured, detailed optical characteristics which XenomatiX is using for automotive OEM test requests. As Siemens is a specialist in combining simulations with tests to allow accurate simulations and fast design, they acquired new lidar test experience in this partnership.

As a result of the partnership, OEMs, Tier Is and all lidar suppliers have access to a tool that allows them to accurately simulate lidar performance in different scenarios, whether purely in simulation or including HIL and SIL. In the quest for validating and certifying ADAS and AD functionality for a high number of scenarios, required but undefined by the automotive community, Siemens can now propose an additional multiplicator to enhance and augment scenario testing.

Validating the simulation model

The Siemens physics-based lidar simulation model has been validated by comparing the lidar model behavior with the behavior of physical XenoLidar in multiple circumstances.

Siemens Digital Industries Software is the reference expert and world leading partner in combining simulation and test environments in the domain of Noise, Vibration and Harshness (NVH). Siemens has a proven track record of validating and optimizing simulation models and processes with experimental test data. While this principle already applies for decades in the automotive design in order to accelerate the new-model releases faster and more reliably, in the past decade this became very actual also for ADAS and AD developments. XenomatiX is now becoming a reference in this world.

Simulation always includes hypotheses of the real world and can only approach reality to a certain ‘theoretical’ extent. By ‘correlating’ simulation models with the real world, whether FEA, MBD, NVH, durability or ADAS/AD modelling, the same approach applies, which is checking your simulation model with the real world to validate and prove if the simulation gives the same output as the physical tests. Output from a lidar means point clouds and detections and perceptions of objects, humans, and animals.

In this project, multiple lab and outdoor tests have been simulated and performed in the real world. Both results were compared, differences were investigated and translated to parameter settings in the model. Adapting these parameters in the model to become more accurate to the ‘real life’ conditions is the essence of ‘tuning’ a simulation model according to the correlation with the real world. Iteration in this process is standard practice to obtain fully reliable simulations of the real world. This gives further insights into the functioning of the lidar and perception software.