Offshore process facilities pose dimensional control challenges from cradle to grave. New construction requires managing tolerances between topsides and hull structures, often fabricated in different parts of the world under widely varying environmental conditions. After hurricane damage, leaners are hazardous workplaces but have to be documented quickly and accurately for repair; downers need to be studied for decommissioning. Meanwhile subsea installations have intricate geometries that often are not well documented – accurate fabrication of new tie-ins can require going back down to take acoustic measurements, eating money and schedule.

Fortunately offshore dimensional control has made great strides over the last decade. After Hurricanes Ivan and Katrina in 2005, damage repair efforts in the Gulf of Mexico spurred the oil and gas industry to still wider acceptance of 3D laser scanning and other advanced DC tools. At SPAR 2007, March 26-27, Sugar Land (Houston), TX, presenters in a Process, Power, Offshore/Marine track will document how advanced dimensional control is shortening schedules, reducing cost and improving safety for the offshore oil and gas industry. The track will also look at coming advances and what remains to be done.

Subsea metrology and deepwater digital fit-up

How digital fit-up can cut time and cost from new deepwater installations will be described by Brett Morry, survey specialist with the BP Atlantis Development Team, and Jan Garmulewicz, president of UTEC Survey, Inc. The BP Atlantis field, located 150 miles south of New Orleans in 6,760 fsw, is the third-largest field discovered in the Gulf of Mexico. Traditional deepwater DC often involves going subsea and using acoustics to measure distances between installed components. Morry and Garmulewicz will show how laser scanning and dimensional control techniques applied to manifolds and other equipment on land prior to subsea installation, combined with acoustically acquired position data about the pile or other target installation point, can eliminate much deepwater measurement while still providing high-confidence fabrication and accurate first-time fit.

Using photogrammetry as a subsea metrology tool will be the subject of a Technical Seminar by Frank Prytz, photogrammetry section leader with Blom Maritime AS, a world expert in subsea DC services.

Reducing TIC

Offshore dimensional control goes well beyond laser scanning, sonar, photogrammetry and other data capture tools – that’s what Stan Wiggins, corporate planning and scheduling manager with Frontier Drilling, will discuss at the conference. Frontier provides offshore drilling and production services, and specializes in operating and managing offshore drilling rigs and floating production vessels. Presenting with Wiggins will be Dave Penman, director of offshore DC service provider Hi-Cad Ltd. Penman notes that oil and gas owner/operators are now using DC from cradle to grave, and after the 2005 hurricane season the industry became well acquainted with the advantages of collecting needed information more quickly and accurately than with older methods – all while reducing total installed cost (TIC) through reduced hours spent offshore, POB (personnel on board) and travel costs. Wiggins and Penman will illustrate with several projects and examples.

Decommissioning challenges

Decommissioning is another big concern for the oil and gas industry. Producers take their environmental responsibilities seriously and understand the need to plan facility end-of-life activities. Clearly this is something the public is sensitive to as well – witness some high-profile incidents such as the Brent Spar case. At SPAR 2007 we’ll look at current and emerging technologies that promise help for these efforts.

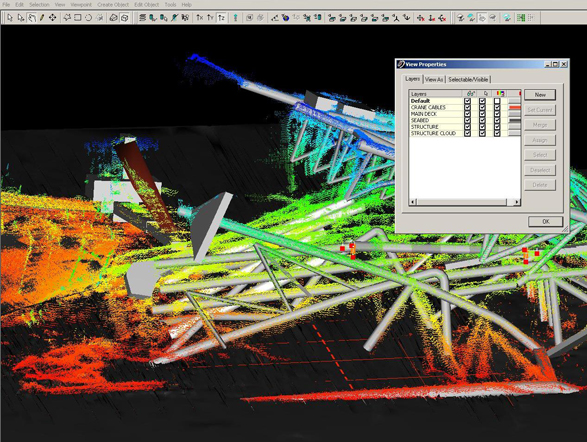

What’s new are initiatives to take 3D modeling and visualization techniques first developed for surface applications, and apply them to decommissioning. These look to be valuable tools for interpreting sonar and other data used to document downed platforms – the difficulties are clear as well. Subsea acoustic returns are sparser data sets than laser scan point clouds taken above water. Seabed geometry is usually obscured by slime and encrustation; it’s almost certainly broken and deformed as well. Given all this, generating reliable 3D models of seabed geometry remains very much an art – it requires the ability to understand and interpret sonar data, plus drawings or models from the project’s design phase, plus advice from structural engineers on likely failure modes. The challenge is to knowledgeably combine these inputs, clean them up, produce a 3D model – and accurately characterize the degree of uncertainty in the model, no matter how photorealistic it may look.

These issues will be the subject of a case study by John Dooman, project manager at EDG Consulting Engineers, and Win Thornton, president of WINMAR Services, Inc. After the hurricane damage in the Gulf of Mexico in recent years, some platforms now sit on the sea floor and are scheduled to be either abandoned as reefs, or completely disassembled and returned to shore. Dooman and Thornton will describe their work with a major oil company to model sonar data from downed platforms to raise efficiency and safety margins in the decommissioning efforts. This session will be the focus for a vigorous discussion of current best practices, what’s feasible with today’s technologies, and what further advances may be on the way.

Data management

How to manage 3D dimensional control and related data will be the topic of a Technical Seminar by Jason Matsumoto, president of offshore-focused DC service provider Grenland AsIs North America, Inc. The industry has a growing need to store and classify huge amounts of 3D and other data, then make it readily available to a worldwide user base. Matsumoto will look at how currently available information technology can address the problem.