In 2019, GeoCue Corporation announced the industry’s first drone lidar/imagery fusion sensor, True View 410, to enable surveyors to produce 3D colorized point clouds, oblique imagery and orthophotos in a single flight. Six months later, Lewis Graham, President and Chief Technical Officer of GeoCue, says the use cases for the True View 410 continue to multiply. “We are extremely pleased with the way this system is being deployed, often in situations we did not envision during its design.”

Assessing Earthquake and Severe Road Damage

Following the 2019 earthquakes in Puerto Rico, GeoCue’s business partner Innovative Imaging and Research (I2R) used the True View 410 sensor to help the Civil Air Patrol assess the damage by flying an area and immediately processing the data before the next flight. However, a photogrammetry solution would take a long time to process, and skim over the first surface of complex topologies, such as debris fields with no penetration into nooks and crannies. On the other hand, GeoCue’s sensor provided high fidelity colorized point clouds with processing taking a bit less time than that of the collection itself.

Recently, the Alabama Department of Transportation (AL DOT) asked GeoCue to assist with imaging an area of severe road damage on a major roadway, Alabama 231, caused by heavy rain. With True View 410, the data was collected and processed in one evening. Additionally, GeoCue’s True View Evo, the software bundled with a True View 410 sensor, helped to deliver a ground model as well as derivative products, such as a gridded DEM and topographic contours.

Stockpile Volumetric Analysis

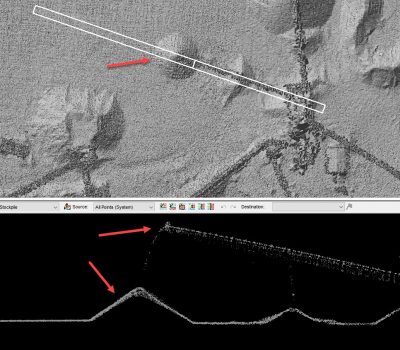

Stockpile in plan view (top) and profile view (bottom)

Wiregrass Construction, an asphalt pavement mix producer, aggregate and construction company, uses photogrammetry to calculate stockpile volumes for quarries, asphalt plants, and construction projects. However, when stockpiles become overgrown with vegetation, lidar works best, and that is where the True View 410 makes a difference.

By providing fused, concurrently collected point cloud data and imagery in a single flight, the True View 410 helps Wiregrass Construction to collect volumetric data faster and more efficiently. Together with the True View Evo software’s automatic ground classification tool, automatic stockpile toe tool, and volumetric analysis tools, the visual cues of imagery and the vegetation penetration of lidar easily separate vegetation from the stockpile surface to get an accurate volume.

The future of GeoCue’s True View Ecosystem

The True View 410 is available under two different business models, a standard system purchase or as a subscription service. Due to the pandemic, GeoCue will be running training sessions aimed at users who will be deploying a True View system within the next month, and in-depth, 3-hour seminars for current users.

In the future, GeoCue plans to release the True View 250, a dual camera direct geopositioning system designed for the DJI M200/M210 series drones. Also, as part of RIEGL’s partnership, GeoCue will launch the Riegl-based 3D Imaging Systems in Q2 or Q3, featuring dual cameras and the Riegl miniVUX2.

“As you can see, the True View Ecosystem is a large and ongoing development area for our company,” Graham wrote. “We see a bright future in drone mapping where rapid response and processing is the norm. Look for more innovative products to roll out from us over the next several years.”