At SPAR 2009 in March, Ford Motor Company’s Don Deming and Pointools’ Faraz Ravi impressed audience members with examples of segmented 3D laser scan point clouds for improving Powertrain manufacturing engineering processes. Virtual manufacturing efforts began at Ford Motor Company about eight years ago. Then, the philosophy was that CAD data would streamline product development. It helped, but not to the level management had hoped for, and design still required up to two to three years’ lead time, Deming said. Now the leading U.S.-based auto maker is achieving more than it imagined with simultaneous engineering, design and process development using 3D data. Deming told our SPAR 2009 audience that “Virtual engineering brings everyone together, and we get signoff before we even cut or assemble the first piece of metal.” Ford has been engaged with laser scanning products for 15 years; its current solutions include those from FARO, Romer, Pointools and Geomagic.

Deming shared examples of a complex GT 500 engine block casting that was readied in about three months. A CT scan of the engine block helped engineers to view flow, porosity and more. For virtual machining tasks, scans help to set up cutter pad tools and identify forces generated on the parts.

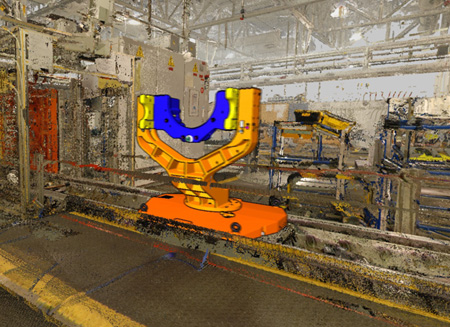

Ford uses Siemen’s Tecnomatix software suite for new programs as well as existing products that need to be studied. This allows process and component engineers to pull things apart, conduct simulations and view a product in the same room at the same time, quashing the old linear method of development, which was disjointed and time consuming. In addition to efficiency, the Ford division is also saving time and money in the process. Deming told of a CT scan performed on a pallet used for transmissions. A “gap analysis” of the transmission showed engineers where the clamps were on the transmission itself and discovered some clearance issues. The part was re-engineered and re-analyzed within about two weeks, and Ford saved the cost of purchasing the original order for 160 new pallets at $19,000 each.

In the past, Ford remastered and remodeled AutoCAD 2D details, but the process was very expensive. Now, the company is cooperating with Pointools and FARO on hybrid models that mix CAD models with 3D meshes. The color capability of the FARO scanner allows Ford to use points by themselves. “The human eye can put together a realistic view of points if it’s displayed correctly,” Deming said. Using the hybrid approach of using whatever is needed—points, meshes, etc.—has allowed Deming and his team to do about 80-90% of the work they need to do. And Deming says it takes very little processing time.

Pointools continues to prototype the solution that supports a hybrid approach of 3D data use, where models can be of different types but still have the ability to move them around and produce a simulation to test out scenarios. Faraz Ravi, founder of Pointools, says his company has built technology that enables visual mockup of manufacturing scenarios but not to the point of taking the points to final engineering. “It’s really allowing feasibility checks that are cheaper because you don’t have to model assets—and it’s a fairly quick process,” Ravi said.

Ravi showed the point cloud example of the pallet Deming spoke of that was segmented to identify interferences, stating that users can drop in STL and CAD models as well as raw point clouds. Users can then duplicate items and reconfigure the direction of lines. “The ability to do that practically in real time at an engineering meeting is what we’ve been working on,” Ravi said. “What we really require is 3D platforms to adopt point clouds on a much wider basis, and we are focused on providing the software components to enable this to happen.” He said 15 years ago, several CAD programs took in 3D models, and in the same way, he wants to see the “democratizing” of point clouds and the ability to manipulate them in the same way as CAD data. He says one obstacle is the survey industry, which views point clouds as immutable (absolute) objects that shouldn’t be played with in this way. We are, however, seeing an uptick in vendors who support point clouds directly.