The adoption of 3D scanning for industrial, infrastructure, mining, and construction is rapidly growing. While the tools and sensors used for scanning have improved, the processing workflows have not kept pace, and manual classification has become a significant bottleneck for time and staff resources. By leveraging data, ScanX aims to provide better and faster data analytics and solutions specific to the job at hand.

ScanX utilizes machine learning and artificial intelligence to automatically classify 3D point cloud data via a web-based application. Their software is designed with a clear-cut but customizable purpose: to ingest scans from whatever devices used to collect them, to process the point cloud, and visualize it on the web. By adding intelligent processing to the point clouds, ScanX helps its customers move away from traditional desktop software, using advanced cloud computing to go beyond simple classification.

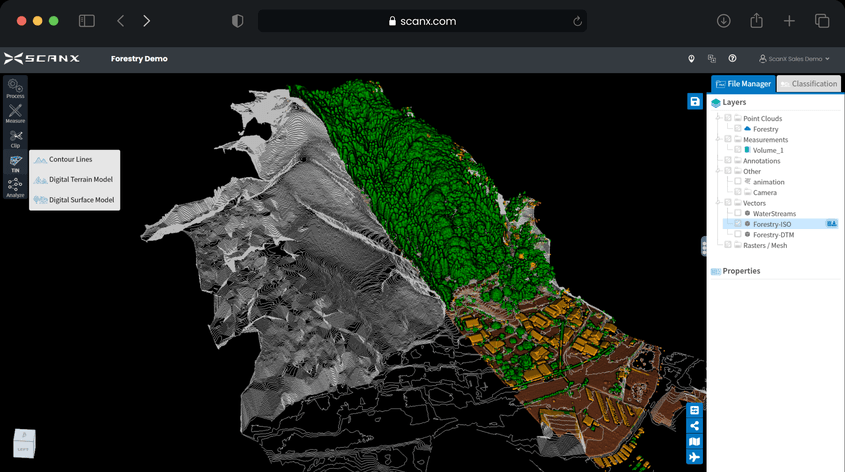

Classified data and compiled ground contours.

Handing over the hard work to AI

ScanX was founded by a pair of engineers who have years of experience doing field scanning and processing work, spending hours painting, slicing, moving contours, and making their scans clean enough to use for their intended purpose. This experience has been directly folded into the backend processing that ScanX provides. Since they know the process from experience, they found they could design a system from the inside out that does the same things, but more quickly and without manual help, says Hong Tran, CTO of ScanX.

“It’s kind of like we’ve done all the hard work for you. We do the onsite filtering and cleaning, and we handle all the cloud processing, so we batch process everything. We’ve handled all that.”

The backend processing and analytics assisted by AI and machine learning are designed to free up time for the engineers and experts to use the resulting data to make decisions – something they are experts in.

Teams can then use these insights to track, monitor, and measure projects on and off-site and share the results of the analytics with stakeholders in a secure environment.

The portal itself is also designed to be user-friendly. You enter the platform, choose the type of scanner, and then you have some options for choosing resolution and defining what will be cleaned up— including the removal of duplicate points. The scan file is then dragged and dropped into the interface and processed in the cloud.

The power of collecting and organizing data

By providing a central, web-based platform, ScanX can also assist with integrating data from multiple sources – for example, indoor scans performed with a SLAM backpack, Terrestrial laser scanner and UAV surveys of a building’s exterior. By centralizing, organizing, and making the scans readily available when needed, the critical information can be pulled up by multiple stakeholders from varied locations and won’t be stuck on the computer of a particular surveyor.

While several companies are competing for the AI cloud processing software space, it seems that ScanX has taken a slightly different approach. Rather than looking at a workflow and trying to see where AI could fit, they translated their own experience to automating tasks they were extremely familiar with – but spent way too much time on.

Solving real-world problems

ScanX has focused its work on creating a platform designed to address real-world problems and use cases in civil engineering, mining, road and earthworks, forestry and more. By adding layers of analytics, visual indicators (like height mapping, heat maps, etc.) on top of reality capture scans can provide critical information that is easy to interpret and take action on.

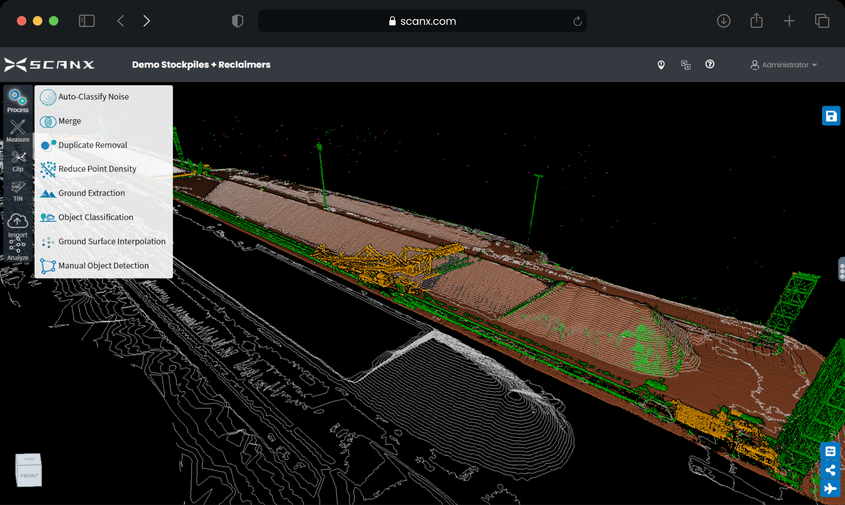

Ground can be automated and quickly extracted from noisy scan data.

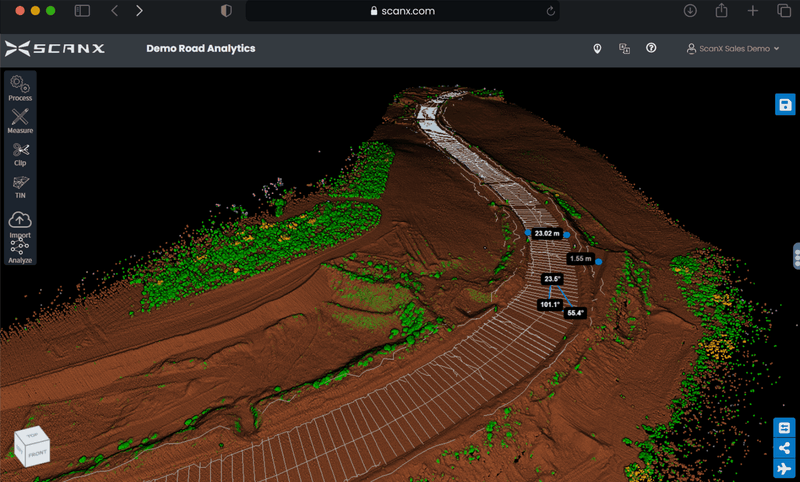

One particularly compelling example involves vehicles that are utilized in large-scale earthworks operations. For safety, roads on job sites are created to adhere to precise width requirements to allow heavy equipment to pass on a single road safely, and berms of material are laid in place at the edges of hazardous areas to prevent trucks from going off course. These standards have their specific requirements but can take hours of manual checking to ensure they are correct, and even then cannot be constantly monitored to ensure that they are still safe. With repeated reality capture scans, the data can be uploaded into ScanX’s platform and have analytics overlaid – in this case, a heat map demonstrating areas where the road has been constructed at too narrow of a width.

Scan of a quarry road with measurements displayed.

ScanX has processed over 3,000 projects, is developing patent-pending solutions for even more industries, and is currently looking for more companies searching for better workflows for their projects. Interested users can learn more about trialing ScanX for free here.