Participating for the first time at the AWE 2021 12th Auggie Awards in Santa Clara, CA, 3i Inc.'s Beamo recently beat 83 other XR solution nominees, including finalists such as Arthur by Arthur Technologies, XR Guru by HoloPundits, Librestream Onsight Connect by Librestream, experienceCloud by room AG, and HP Reverb Omnicept Solution by HP, to win the trophy for Best Enterprise Solution. So, what is it that the company offers?

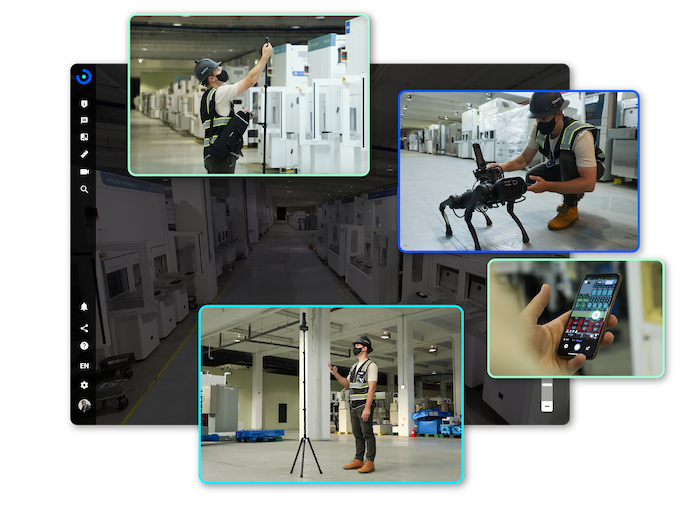

As an enterprise-grade digital twin solution for mission-critical facilities and a member of Born2Global Centre, Beamo launched in April 2021 to help connect people and places by virtually teleporting them to hard-to-reach places and providing an accurate, contextual, and immersive digital replica of work sites. By using a smartphone and an off-the-shelf 360° camera only, the idea is to provide a simple of way of capturing a 360° view of work facilities and create an immersive digital twin in minutes, unifying remote teams under one intuitive platform to support their whole lifecycle.

Designed for Inspections, Documentation, Maintenance, Project Management, and Training, Beamo promises to make site surveys 30% faster by replacing traditional photo reports that can take up to a week to create. After capturing the 2D panorama images with a smartphone or 360° camera, the Beamo Portal processes, indexes, and rebuilds the images into a 3D digital twin using Beamo’s proprietary machine learning visual cortex called Beamo.ai, forming 360° spheres. To understand how far and to which direction a user has traveled so that the 360º spheres are correctly positioned, the company takes advantage of the smartphone’s gyro sensor and accelerometer and uses SLAM (Simultaneous localization and mapping) technology to pick up the unique features of the surroundings, understanding how things are moving through space. All of this is happening locally from the smartphone device which greatly reduces the computing process necessary for creating a digital twin. The video below demonstrates how this process goes when using Beamo to capture a digital twin.

To replace the different smartphone sensors and expand digital twin creation capabilities for industrial clients, the company developed Beamo Pathfinder, a more flexible and robust solution for indoor mapping that can be held in a pocket and uses Intel Realsense technology. The Beamo Pathfinder features a VSLAM tracker, a tracker with dual camera, a wide FOV, and a high sensitivity IMU, providing greater awareness and endurance regarding sudden movement within all axes, vision change, and movement speed over the smartphone-only solution. It also provides improved accuracy, lower power consumption, and better 2D panoramas storage capacity, and enables users to skip a couple steps (alignment, import time), and can also utilize the full functions of Beamo App at the same time (like tagging while capturing).

Furthermore, the Beamo App lets users attach additional pictures, videos, and other files on the floor plan to document observations and environmental conditions, allowing surveyors to get the job done faster and focus on capturing while someone else tags. Tagging, measuring, commenting digital twins, virtual meetings, and side-to-side comparison of work progress over time, are some of the app’s features available. According to the company, reporting times are cut by 90% and results are easier to share and to retrieve or leverage with the passing of time.

Beamo already has various case studies to demonstrate the various advantages it provides against traditional methods. For example, a major telecommunication company used Beamo to improve efficiency over traditional field survey processes, and ended up saving $10,000 per engineer per year in travel costs, reducing 30% of the time needed to conduct a site survey. Together with collaboration, quality and workflow improvements on 150 Data Centers and telecommunication buildings, the company will end up saving $300,000 per site by the end of 2025.

In a different industry, a major manufacturer of electronic components used Beamo to avoid stopping manufacturing processes and freezing assembly lines, paper-based documentation, and unnecessary on-site travel. It also resulted in better collaboration within teams with a very high degree of customization for the group management, better maintenance record and continuity between shifts, improved information segmentation and security, depending on member access levels and task, as well as better onboarding of new recruits.

Finally, a major Japanese Airline company is exploring the creation of digital twins of its hangars and warehouses with Beamo for remote inspections, information sharing and remote collaboration, and to capture the outside of each aircraft, for visual inspection to provide general well-being of the exterior, and progress of maintenance work. By visually inspecting aircraft cabins remotely using Beamo, the airline has reduced maintenance costs and errors, and improved MTTR by 30%. In addition, since their specialist technicians only need to travel to sites where they are most needed, the airline has reduced their travel costs by 30%, improving their morale.

Regarding how the pandemic changed the demand for digital twins, Dr. Pyeon, Associate Director and Associate Professor, San Jose State University said in an interview that “now more than ever, it’s difficult to find experts and send them to remote locations, for site inspections and maintenance. You have their health at risk. You have to deal with quarantine restrictions across different locations. These only increase risks and costs.”

“For the longest time, we could never imagine that there’d actually be a way to manage facilities and NOT have your teams be onsite. But now, managers are realizing that digitization for facility management is possible and is actually vital to adapt to current times and be competitive in the market. Your teams, one way or another, may still need to visit the site, but their visits can be significantly reduced, optimizing the amount of work they can do with just a few visits. Managers are now realizing the benefits digital twins can bring to companies, like cost savings, improved collaboration, and optimized human resources.”

With the global 360° camera market set to outgrow the 3D scanner market with a projected USD 2,993.6 million (forecast period) against USD 1,324 million by 2026, respectively, Beamo strongly believes 3D Scanners are a thing of the past. Having completed an investment of $24M in late September 2021, Beamo’s parent company, 3i Inc., plans to invest significantly in scaling out the company with multiple open roles in recruiting, marketing, customer success, design and engineering, as well as key investments in the 3i brand experience in the market over the next year. Let’s see what the future holds for Beamo and its 3D-scanner-free solution.