Photofly rebranded as 123d Catch

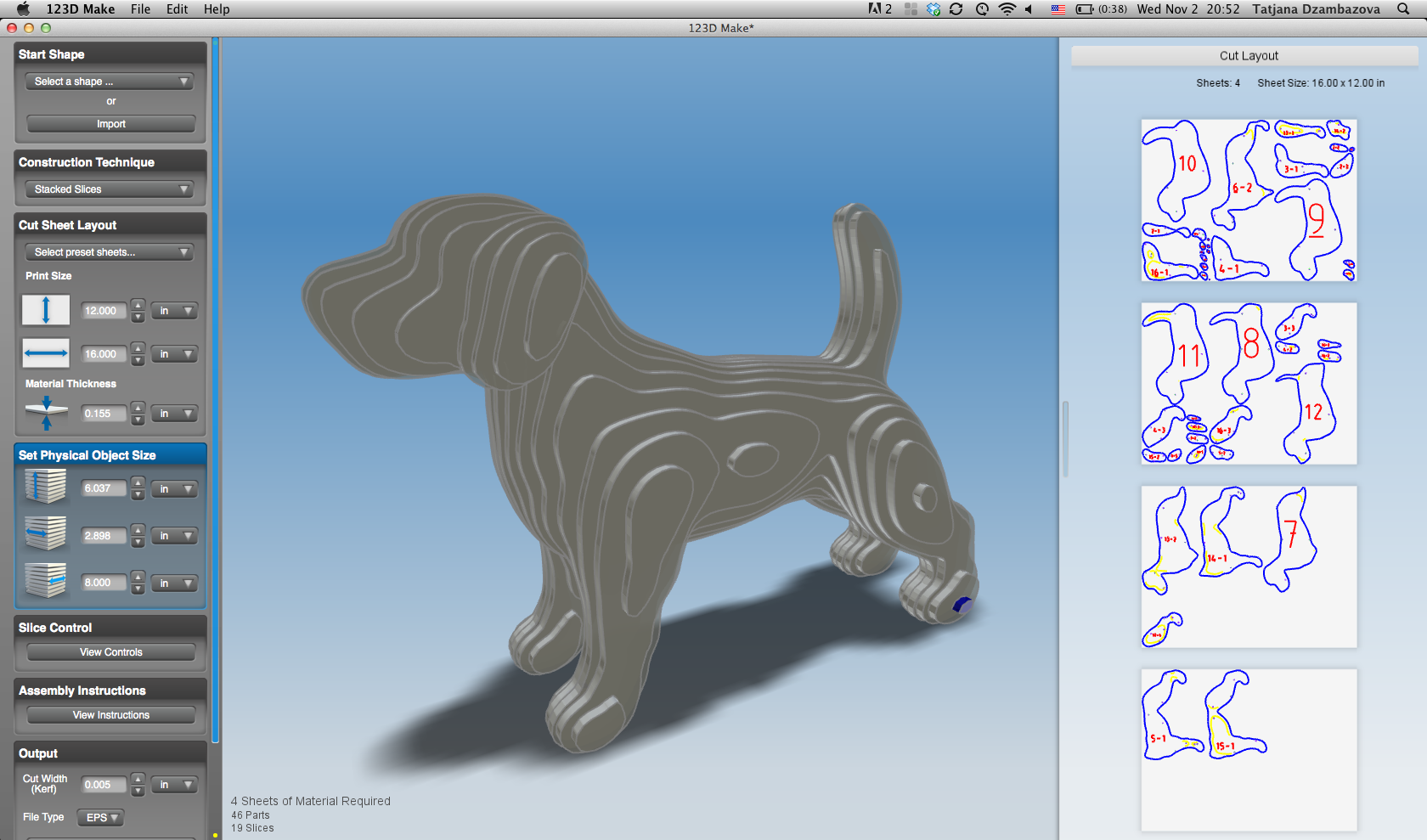

SAN RAFAEL, Calif. – Autodesk took the bold step last week of rebranding one of its most buzzed-about new technologies, the photogrammetry offering Photofly, as 123D Catch, part of an announcement that the 123D family is growing. Graduating from Autodesk Labs to a “Technology Preview” status, 123D Catch, which creates 3D models from collections of normal digital pictures, is accompanied by 123D Make, which takes 3D models and converts them “into a 2D cut pattern that can be easily assembled in low-cost materials like cardboard, wood, fabric, metal or plastic,” according to a press release.

These two new releases join the original 123D, which “enables makers to bring ideas to reality by designing highly precise and makeable objects,” and 123D Sculpt, an app for sculpting and painting 3D creations on the iPad.

All of these are available for free download here. Note, however, that for the time being Catch is PC-based and Make is Mac-based.

“Both technologies come from different development programs,” said Hendrik Bartel, Autodesk product manager, by way of explanation in an interview with SPAR 3D. “Our philosophy is that we want to be mobile and cloud-based. This early days and we’re not done.”

The question is, of course, for professionals eyeing these tools: Are they for us? Or are these just toys for the consumer space?

As an initial reaction, see this presentation Autodesk director of reality capture made at the recent SPAR Europe:

Bartel acknowledged that this is primarily a consumer play for now. “From a big-picture perspective, what we’re really trying to do is build tools that allow anyone to unleash their creativity, their ideation, their design,” he said. “We feel there’s a designer in everyone out there.”

By establishing Autodesk as a consumer brand, building the company’s name among the masses, it helps the company be the default when someone graduates from the consumer to the commercial and professional spheres.

There’s another element of priming the pump, too. “We’re very concerned about who the engineers of tomorrow will be,” Bartel said, “and will there be enough of them.” Autodesk hopes maker-focused products like 123D, along with other game-like apps, will “make mechanical engineering seem fun,” Bartel said. (Just this week, Florida announced it may reduce the price ofengineering degrees to encourage students to take that path at public universities.)

However, creative professionals will find useful tools in these releases as well. Those in manufacturing could find that Make helps with rapid prototyping. If you’re a start-up and can’t afford a 3D printer, Make will allow for models of products to be delivered to your door in quick, cardboard fashion. Those who might have a presentation and are looking to create a quick model of a working idea for display could do something similar.

“Yes, absolutely use this is for real product development,” Bartel said of Make. “The inherent difference in using cardboard vs. a 3D printer, there’s a massive difference in cost there. I could see using these rapid cardboard prototypes as an even earlier designer review stage, something you just want to visualize in a classroom setting, rather than with hundreds or thousands of dollars from a 3D printer.”

“Make is bringing a completely new deliverable into the b2b world,” he said. “Visualizing something for a board room meeting not only as a point cloud or a model, but all of a sudden you could bring a to-scale model into the clients for how a site layout will be.”

“And from the Catch world,” he continued, “it’s truly magic what we’re doing here. It’s so breathtaking to see how you can easily take 40 photographs of a statue and send the images to the cloud and within minutes you get a completely rendered wire frame model and it has such an intricate amount of detail.”

Is it up to accuracy standards with that of a laser scanner? No. But maybe all that means is “not yet.”

.jpg.small.400x400.jpg)