Austria’s Johannes Kepler University announced a 3D scanning technology that may be even better suited for consumer mobile applications than solid-state lidar. Scientists in the Institute for Computer Graphics had developed a transparent plastic film that is 0.3 mm thick, flexible, and capable of capturing 3D depth information.

Professor Oliver Bimber, head of the institute, says the film “can take on any shape and size, making it easier to use on a daily basis.” He says the film will provide 3D scanning in a form factor well suited for tablets, smartphones, and other consumer devices. Currently, the 3D sensors used for mobile devices are mechanically complex and bulky.

How Does it Work?

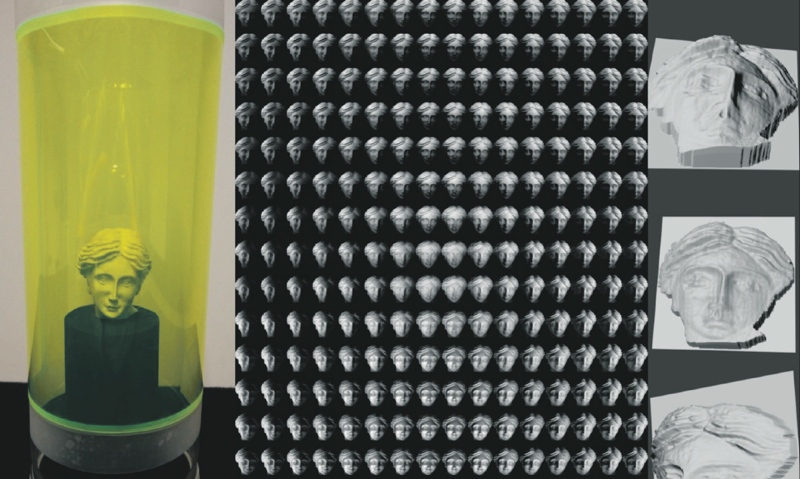

The sensor itself is passive, so it is accompanied by a small external pico projector that illuminates an object with “a series of random noise patterns.” The film then uses a special fluorescent dye that measures the “light signal” from the illuminated object. That means no optical elements (like lenses) are necessary.

To process that data into a 3D image, Bimber and his team are currently an approach from “a fairly new sampling theory known as compressive sensing,” in which the light measurements are used to generate 256 views of the object that “differ only in their shading.” Once those images are generated, the team applies a reconstruction process known as “shape from shading,” which can determine the geometry—and thus the depth information—of the object being scanned.

The researchers say the film they’ve presented is essentially a proof of concept at the moment, with more developments to come. “In the future,” says Bimber, “the random noise patterns required for scanning will no longer be generated by an external pico projector, but rather by a coded aperture located directly within the second layer of film.”

The result would be a 3D scanning sensor integrated completey into a film less than a millimeter thick.