Renovating, rebuilding and refurbishing nearly 800,000 square feet of building space on Brussels’ Rue Royale is the goal of the $140 million Kanselarij Cluster Restructuring project – part of a master plan by financial services provider Fortis Bank to optimize and upgrade its portfolio of corporate buildings in Brussels. At the heart of the Kanselarij Cluster will be a new multifunction atrium connecting five technically and functionally independent buildings, all with demanding sustainability and environmental requirements. Many structures in this historic district abutting Brussels’ Parc Royale date to the 17th century, and strict rules govern how they may be modified. Integrating the site’s existing classical buildings into the new 21st-century cluster posed challenges for both designers and engineers. Early in the project, Fortis decided to survey 100% of the site using 3D laser scanning.

According to Fortis’s Philippe Monserez, Division Manager, Corporate Real Estate Projects Brussels, the combination of schedule pressure, large project scope, need for accurate data, near-impossible access to site rooftops, concern for surveyors’ safety, and highly detailed architectural façades made laser scanning the obvious choice.

Service provider Globe Zenit NV, Zandhoven, Belgium, reports it used three different laser scanners to capture data – Leica HDS3000, Leica ScanStation and Trimble GX – from 35 different scan locations. Fortis’s Monserez says he asked Globe to use multiple scanners in order to compare setup times, accuracy, speed and other attributes. More than 45 million points were collected in all; the registered scan dataset exceeded 3Gb.

To capture and manage the scan data, then produce MicroStation DGN files conforming to the client’s CAD conventions (Fortis CAD Charter v.8.3), several software applications were used: Trimble PointScape, Trimble Realworks, Leica Cyclone, Bentley CloudWorx, MicroStation V8 and MicroStation Triforma.

Continued

3D data key to communicating with stakeholders

3D laser scan data has been used to inform effectively all project phases to date. Monserez notes that from project inception, the most critical challenge has been communication among project team members, Fortis Steering Group members, and stakeholders from the City of Brussels, the Region, and the Administration of Monuments and Sites. To address this challenge, the project manager and the program director decided to carry out both pre-design and design in 3D. Total data volume in the pre-design phase for architectural and construction work in MicroStation XM was about 1Gb. Detail designs for HVAC and other disciplines are currently being developed in Bentley Mechanical and Bentley Electrical.

To streamline and facilitate communication with stakeholders inside Fortis (Management, Steering Group, and Merchant Banking), the project team implemented a dual strategy using both Google Earth and 3D PDF. Due to project scope and size of datasets, this posed some challenges for the Bentley software as well, Monserez notes.

To improve collaboration and communication among project team members (architects, electrical engineers and mechanical engineers) about conceptual and technical issues, the project team explored the use of Bentley Navigator. Improved display of large models in Bentley Navigator 8.9.4 made handling of interior views ten times faster than with previous versions, with fairly good navigation, Monserez reports.

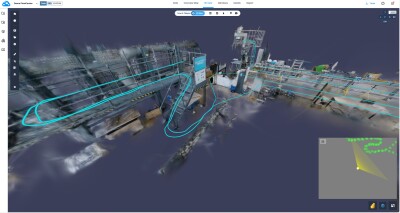

For assessment and communication with the authorities of the City of Brussels, the Region, and the Administration of Monuments and Sites, the project team focused on data integration. To virtually integrate the Kanselarij Cluster Project into the surrounding environment, Fortis asked VRcontext to convert a series of datasets into its Walkinside Viewer for real-time review: MicroStation files of 220,000 simplified buildings representing the City of Brussels, covering 400km²; MicroStation DTMs extracted from aerial stereophotographs from Aerodata, which provides Google Earth data for this area; 8-inch-resolution aerial photography textures draped onto the MicroStation DTM covering 400km²; and 3D MicroStation model of the Kanselarij Cluster Project created entirely with feature modeling.

The project team has also been in contact with Materialise to produce 3D printing output of the global project and the interior design and layout.

The project began in the first quarter of 2006. Two major milestones have been achieved to date: submission of the building permit to the authorities of the City of Brussels (December 22, 2006) and start of heavy site preparation work. Fortis expects to have detailed designs ready to initiate the tender process this summer. Demolition and structural work is expected to start at the beginning of 2008, with the goal of delivering a fully equipped complex by June 2010.

Project participants include the Fortis project team, Storme-Van Ranst Architects, Boydens Engineering, Cauberg-Huyghen Environmental Consultants, ELD Partnership Structural Engineering, Globe Survey Services, 4D Select, VRcontext, Aerodata, Cad-Phil, Bentley Belgium and Bentley worldwide.

The Kanselarij Cluster Restructuring project was recognized with a BE Award of Excellence in Los Angeles two weeks ago. A feature of Bentley’s annual BE Conference, the BE Awards showcase customers’ civil, plant, building and geospatial projects. This project won in the category of “BIM for Sustainable Design.” Other projects that used 3D laser scanning will be covered in future issues.