“The roots of NavVis and mobile mapping lie in robotic and AI research.” NavVis CTO and Co-founder Georg Schroth.

Our vision to bring the power of GPS and maps to buildings and sites root in 2009, when the idea of NavVis was first born at the robotic and AI research labs of Technische Universität München.

Here’s where a group of young scientists and engineers developed the core technologies that form part of our company’s products today. From the very beginning, we used our backgrounds in robotics, machine learning, and software to answer the core questions about spatial data of buildings and sites and how it could always be kept up to date.

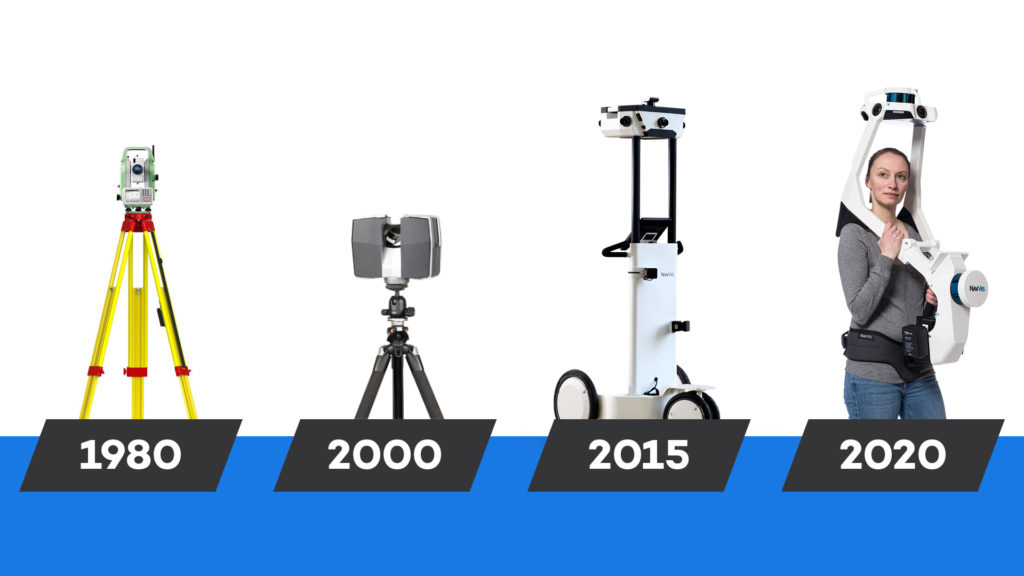

In contrast to existing products at the time, we were certain that Simultaneous Localization and Mapping (SLAM) – a foundational technology for any robotic system – would be vital to capturing the real world. The process of mapping and modeling would be made drastically simpler and faster.

Going back a little further, I saw SLAM’s potential first-hand in 2007 during my time at the GPS Lab at Stanford University. SLAM was the basis of Stanford’s entry to the DARPA Urban Challenge that year, succeeding with the autonomous car “Junior” – basically the starting point of all autonomous car developments ever since.

So where are we today, in the present moment? The reality capture industry is about to go through another major change, and once again SLAM-based mobile mapping will play a huge role. For quite some time already, mobile scanning solutions are much faster in capturing the built environment. But it took years of research and development to bring accuracy to the level of millimeters and make it a standard “tool in the belt” for industry professionals. While SLAM-based mapping can cut the time and effort to update a building or site’s spatial information by a factor of 10, some of our largest customers have pushed us even further.

Their applications range from construction site monitoring to managing the largest factories in the world. Our vision aligns with their needs; they require an almost real-time digital copy of their sites to plan, manage, and make decisions based on data and information they can trust and rely on fully. The equation in those industrial environments is simple: the older the information, the lower its value.

Our SLAM-based NavVis VLX mapping solution is a major leap forward in comparison to individual on-site visits and isolated collection of information together with outdated 2D drawings. Especially in times of COVID-19, it drastically reduces the time and cost to collect the required information and spatial data.

To get to an almost real-time copy of a building, however, sending people through sites and buildings is no longer enough – there is a need for full automation of the process. So, are autonomous robots the solution?

It seems like barely a week goes by without a video or press release showing a laser scanner, camera, or sensor mounted to a legged robot, usually featuring the Spot quadruped from Boston Dynamics. They look cool!

It might be tempting to dismiss them as publicity stunts that are meaningless to your actual business, but autonomous robots’ capabilities are fast approaching an inflection point. Where in the past, stairs, steps, doors, light switches, or any moving objects would have been a massive challenge for those systems, a lot has changed. One step after the other, those robots close the gap to become a reliable support for highly repeatable or too dangerous tasks for humans.

From an economic perspective, we must accept that today’s robots don’t scan faster than humans. They usually move slower due to safety constraints and short-range perception and may not yet anticipate blocked areas. The robot’s additional cost, installation, maintenance, and response to occasional errors also certainly don’t make a single scan cheaper.

The real benefit lies in the repetition, where you can lock-in all your costs and efforts independent of the number of scans. And the equation is simple again: the more frequent you scan, the cheaper per individual scan, but the more up-to-date and valuable your spatial data.

That’s why companies that need spatial data to be updated on an (almost) weekly basis or require data from areas that humans cannot enter should consider looking early into this emerging technology.

Together with research partners, including Technische Universität München and our customers, NavVis has iterated on this concept towards a full solution that goes beyond just mounting a scanner onto an autonomous robot or drone.

Embedding a compatible solution into a customers’ existing fleet of autonomous guided vehicles and infrastructure is the best way to address the challenge. An initial scan of the site is a prerequisite to plan new missions and to register new scans. A tight coupling of the SLAM based scanner and the robotic system is necessary to capture the highest quality of spatial data – an area where NavVis would naturally excel based on years of practical experience.

And ultimately, the spatial data must be made available within hours to as many stakeholders as possible in an easy to use and understandable format. That requires merging individual scans into one accessible digital copy of the facility in a completely automated way.

At NavVis, we see an integrated combination of wearable and robotic mapping systems as the next logical step towards always up-to-date spatial data that you can fully rely on to plan, manage, and decide.

Reach out to our team to discuss, explore and consider your use-case, and let’s take this next step together.

About the Author: Georg Schroth is the Co-Founder and CTO of NavVis. He co-founded the company based on his experience in positioning systems gained during his stay at the Stanford Global Positioning Laboratory and the Information Systems Laboratory as a graduate visiting researcher at Stanford University. He holds a Ph.D. in Electrical Engineering and Information Technology from Technische Universität München as well as an Honors Degree in the Master-level graduate program on Technology Management of the Center for Digital Technology and Management.