Over the years 3D Scanning has become one massive collection of data, of every type, with the focus on capturing higher detail and larger areas of space. However the visualization of this data has been mostly left on a computer screen. Now, full-color 3D printers offer the ability to create physical objects from this data, which has opened up a powerful communication tool to the scanning industry. Since we already capture photo-realistic models of complex data and geometry, this makes it easy to create these color 3D models. Such models help in communications with individuals or groups who may not be able to visualize the data on a screen, making a tactile model more relatable.

The SPAR International conference & exhibition in Houston this year focused on end-to-end business and technology considerations for 3D measurement and imaging for industrial facilities; building, architecture and construction; forensic and security. This focus allowed the industry to see a way to use their data for 3D modeling and 3D printing.

Challenges

Historically, making scan data printable hasn’t been very easy. Issues with conversion of massive point clouds to triangulated data made it difficult to use 3D information for 3D printing. Software programs have matured, and now handle this data in a way that makes it much easier. There are now several industry specific software packages that take point data and make useable surface models that can be leveraged by 3D printers.

The creation of 3D models from scan data has become easy enough that it will help drive the growth of 3D printing in the not too distant future. People are realizing the advantages of 3D printed models, and 3D printing is a very fast growing sector of the 3D industry. One of last year’s fastest selling 3D products was the “personal 3D scanner”.

Still, many think that when you 3D scan something you can just “print it”. This misinformation has been facilitated by news reports and YouTube videos from groups such (even National Geographic) that just gloss over the concept of scanning and data conversion.

One notable example in a major publication showed a scan of a wrench, and then showed it printing seconds later. What was not shown was the hours of CAD clean up on the file to make it a functional 3D model that was “water tight” and had the details that a line of sight scanner would have not been able to capture.

One notable example in a major publication showed a scan of a wrench, and then showed it printing seconds later. What was not shown was the hours of CAD clean up on the file to make it a functional 3D model that was “water tight” and had the details that a line of sight scanner would have not been able to capture.

An even a bigger problem with mass data capture is from land base or as-built scans. These scans will need to be processed through one of many programs to create a printable model that is healed and has mass. This conversion has been done with many types of data sets with great success, as long as the scaled 3D printed model is in line with the physical capabilities of the 3D printer being used. Making sure you understand what is possible from the 3D data collected will insure a good outcome with 3D printing. You need to use the right scan, software, and 3D printer to get the most from your data.

Despite the challenges, taking data to a 3D printed model can be done in just about any industry. Here are just a few examples:

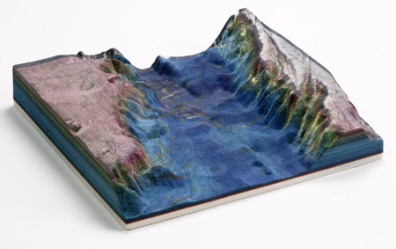

- Landbase models – Meetings planning, community information sessions, archival of data

- Geological models – Permitting, visualization of underground features, analysis of layer porosity

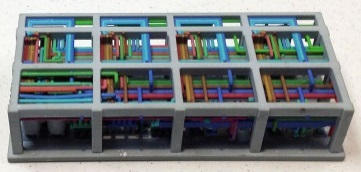

- Construction / architectural – Competitive bid process, Customer / municipality design approvals, visualize clash detections

- Forensic / accident investigation – Litigation models, courtroom re-enactments, scaled forensic analysis, preservation of fragile scene details

- Antiquity preservation – Museum archival, teaching models, world heritage, scaled models of large objects

- Entertainment – Sound stage design, prop mockups, busts for prosthetic modeling, camera path planning, talent reproduction models,