Author: Maureen Gallagher, Solution Marketing Manager, Utilities, Bentley Systems

Committed to Renewable, Reliable Energy

As part of India’s commitment to economic development in the northeast region, and to renewable energy targets aimed at quickly reducing carbon emissions, the government initiated the NER-II Transmission Limited Project. The INR 1.95 billion renewable energy initiative will serve a population of over 30 million residents in India’s most remote areas, aiming to improve the reliability of the power supply, reduce intermittency, and accelerate the penetration of renewables in the northeast region. The Ministry of Power awarded the project to Sterlite Power Transmission, a leading global developer of India’s energy transmission infrastructure projects, to remove infrastructure bottlenecks and create a conducive environment for sustainable power supply.

The scope of the project includes developing transmission lines that span 448 kilometers, as well as design and construct a 400-kilovolt/132 kilovolt substation in the state of Tripura to evacuate gas-generated power across the region from the national grid. “Since gas is a natural balancer for renewable energy, connecting NER to the national grid is critical,” commented Sudanshu Tripathi, head of marketing at Sterlite Power. As the only substation delivering much-needed power to Tripura, it was crucial that construction be completed quickly. Considering the importance of the project for the local region, Sterlite Power had to avoid delays in delivering the substation. Additionally, situated at the foothills of the Himalayas amid dense forest subject to heavy rains and flooding, the project presented complex geographical and environmental conditions, compounded by a tight timeline and an indigenous population resistant to change.

Challenging Terrain; Tight Timeline; Inefficient Processes

To overcome these challenges, Sterlite Power needed to implement efficient design and construction, accurate information flow among stakeholders, prompt and informed decision-making, and rigorous project monitoring. So, they searched for an accurate modeling solution that would deliver right-first-time design. They required an integrated visual modeling environment where they could easily share information and detect and resolve clashes early in the design process to meet the short schedule.

However, their traditional 2D design methods for substation planning had minimal data-sharing potential and did not support the design team’s needs for detecting potential clearance problems between electrical components and support structures. Their current conventional software had limited capability in terms of managing interdependencies and linking design, planning, and construction works. Additionally, it limited their ability to provide real-time visualization of construction progress and facilitate efficient stakeholder communication and resource planning. Sterlite Power recognized that these inefficiencies posed enormous risks in the substation timeline, prolonging inspection, stakeholder approval, and handovers. “We realize the conventional approach has limitations in terms of design optimization, which ultimately leads to delay during project execution,” stated Mayank Srivastava, manager of Sterlite BIM program.

Bentley Applications Digitalize Workflows

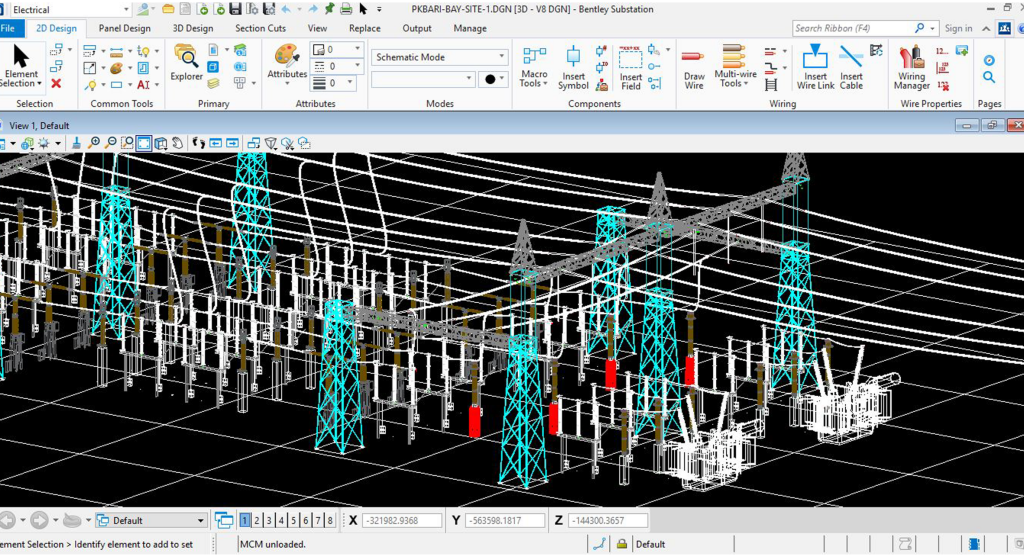

To effectively coordinate design and construction, gain approval from state authorities to lay the transmission lines, and meet the project deadline, Sterlite Power chose to adopt digital twin technology and establish an open, connected data environment. They switched to OpenUtilities Substation and ProjectWise to overcome the inefficiencies of conventional design, establishing a 3D collaborative modeling environment to streamline design workflows, facilitate accurate information sharing, and enable early clash detection among structures and equipment. Using Bentley technology, they developed a digital component library that provided traceability and accountability for design, exporting these component models as symbols to develop the entire substation model layout and ensure proper connection among the equipment. Working in a visually connected data environment with digitalized workflows provided seamless and accurate information sharing among the team and stakeholders to overcome the design challenges and achieve right-of-way clearance, securing permission from local authorities to lay the transmission lines.

To further refine design and enhance construction planning, Sterlite Power adopted 4D BIM technology using SYNCHRO, performing real-time, virtual construction monitoring and simulation. Using the software allowed for robust planning, linking design and scheduling processes and then mapping all project activities to the 3D model for greater visibility into the project plan. The digital model helped visualize the impact of design changes, facilitating accurate, data-driven decisions and avoiding construction errors on site. “Building this model enabled us to maintain interdependencies in an effective manner. It also provides greater visibility of the construction plan in a 3D environment with the project team, which helped them make important decisions quickly,” explained Srivastava. The team also generated a detailed reality model from drone-captured images, which helped them further optimize substation layout and increase design and planning efficiencies.

Setting New Benchmarks for Sustainable Energy Solutions

Using Bentley technology to digitalize workflows and establish a connected data platform based on ProjectWise, Sterlite Power saved a total of INR 1.1 million in resource hours and reduced the project schedule by more than one month. Working in an integrated modeling environment using

OpenUtilities Substation enabled data-driven decisions and early clash detection that reduced rework and saved nearly INR 2.3 million. Through real-time virtual construction monitoring with SYNCHRO, they achieved a 15% return on investment. The integrated 3D and 4D BIM and digital twin solution resulted in paperless workflows, established traceability, minimized information loss, and enhanced collaboration among all stakeholders. By engaging with the community and local state authorities, they gained approval to lay the transmission lines, a breakthrough for the team as prior development projects failed to do so.

Through innovative use of Bentley’s cutting-edge technology solutions, Sterlite Power has set new industry benchmarks for sustainable energy solutions. They plan to extend BIM workflows to asset management and utilize the models for more efficient substation operations and maintenance. Upon completion, the new substation and transmission lines will bring reliable power to 30 million residents of the northeast region while taking India closer to its goal of reducing carbon emissions through reliance on renewables, balancing the intermittency though gas-based power injected from Tripura’s gas power plant.