The business has moved forward as much as the technology

CALGARY, Alberta – Technology is advancing so rapidly in 3D data acquisition that many assume it’s primarily performance advancement that leads a company to invest in an expensive piece of new equipment like Riegl’s VMX-450 Mobile Laser Scanning System. But SarPoint Engineering, which was last month the first company to take delivery of a VMX-450, said it’s the fertility of the business environment that was the key factor in their decision.

“I think the business is ready to accept [mobile laser scanning],” said SarPoint president Chris Tucker. “We’re seeing these monumental changes in the software side of laser scanning, and that’s nothing but evidence to me that the wider market is ready to take point clouds into everything that they do.”

Why else, he wondered, would Hexagon have picked up Leica and Intergraph? Autodesk bought Alice Labs? Bentley bought Pointools? AVEVA bought LFM?

It’s the same growth in the market that led Tucker to merge his firm, Point Geomatics, with that of now SarPoint CEO Robert Radovanovic’s SARPI Ltd on May 1 of last year.

“We worked together on some fairly large projects when we had our individual companies,” Tucker said, “and if I ever needed advanced support in deformation analysis or high-quality dimensional control, I would always just subcontract Rob. And whenever there was laser scanning he needed to do, he’d contact me.”

At the end of 2010 and into early 2011, the volume of work saw the phone calls back and forth increase until a merger only made sense. How did that work out? “We merged with six employees,” Tucker said. “Now we have 17. Things are going very well.”

Those employees are largely geomatics technicians and engineers, along with some environmental staff that deal more with conventional oil and gas surveys. SarPoint stays away from modeling as much as possible, said Tucker: “When it stops being a geomatics product, that’s where we stop.”

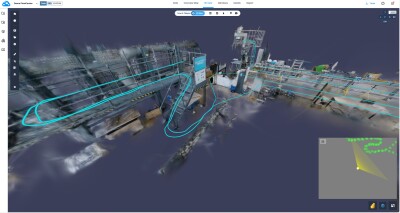

Now they’ve got a new system with which to deliver data. With two Riegl VQ-450 scanners on a mounted platform accompanied by a GPS-INS, the mobile scanning system can deliver more than 1.1 million measurements a second, making highway-speed scanning feasible.

In the short term, Tucker said the low-hanging fruit is in the mining sector, along with selling data to firms that have up till now mostly dealt in airborne lidar data, but that want to move into terrestrial work, providing information to engineering firms and municipalities.

SarPoint will also be partnering with the University of Calgary’s Department of Geomatics, from which the company has hired at least five employees in the past, in developing workflows and working to understand the best ways to acquire good data with the mobile scanning system. “The learning curve will be steep,” Tucker allowed, “but because of our knowledge [in terrestrial scanning]and ties with the University of Calgary, I’m not expecting monumental problems that can’t be overcome.”