At last week’s American Council of Engineering Companies (ACEC) fall conference in Maui, I saw a compelling demonstration of a process that Utah DOT is using to radically reduce road closure times in bridge replacement projects. Rukshana Lindsey, director of bridge operations and research at UDOT, showed how an Accelerated Bridge Construction or “ABC” process is being implemented by her department in a project in Salt Lake City to replace the 4500 South bridge over I-215. [3D laser scanning played a role – see animation below and “Enabling Technologies” on next page.] Traditional methods would have meant closing both roads for six to nine months, she says – using the ABC process, I-215, a major artery, will be closed for just two days, and 4500 South for ten days.

Click here to play 4500 South/I-215 bridge replacement project animation (45.8Mb MPG file). Courtesy Utah DOT

How does it work? Lindsey played an animated visualization [click link above] that UDOT is using to show the public and media how self-propelled modular transporters (SPMTs) will be used to lift the old bridge off its supports in one piece, and carry it to a staging area where it can be demolished. The SPMTs will then pick up the new span, already fabricated adjacent to the installation site. The old span is scheduled to be removed on Saturday, October 27, and the new span moved into place on Sunday, October 28. I-215 is scheduled to reopen Monday – only two days of closure – and 4500 South will reopen after ten days during which landscaping and striping will be completed.

The economic benefit of minimizing traffic disruption is substantial. Lindsey tells us UDOT estimates the economic impact of road closure in such areas at $33,500 per day – about $1 million per month. “Thus, compared with a six- to nine-month road closure, and given the costs incurred by the ABC process,” Lindsey says, “we are saving the public at least $4 million in this project.”

What are the costs? “Total value of this bridge replacement project is $7.7 million,” Lindsey reports. “Of that, construction cost is $6.7 million.” Using the ABC process in this project “cost $780,000 more than traditional methods,” according to Lindsey; this is included in the construction cost. Of the $780,000, $350,000 is the cost of using SPMTs; the remainder goes to construct ramps to aid SPMT movement, and to fabricate temporary abutments to hold the new bridge while permanent abutments are installed. “But the temporary abutments will be reused in future projects, recovering some of that cost.”

Given the number of bridges facing replacement, the potential savings are vast. Nationwide, there exist 590,750 state bridges, according to Lindsey, of which 27% are structurally deficient. “In Utah, we have 1,813 state bridges,” she tells us. “Of those, 5% are structurally deficient” – better than the national average, but still a significant number. “Taking state and local bridges together, in Utah there are 2,846 bridges. Of those, 8% are structurally deficient.”

Continued

Enabling technologies and business processes

“Key elements of the ABC concept,” Lindsey explained, “are SPMTs, InteliSum‘s LD3, and construction management/general contractor (CM/GC), an approach where we all – designer, contractor and UDOT – are partners in developing the project.”

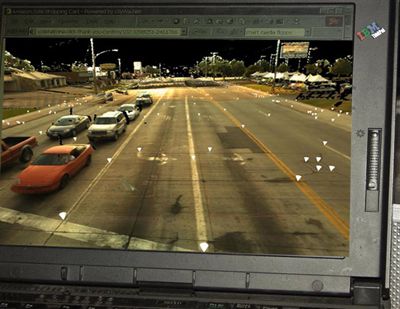

In the 4500 South/I-215 project, InteliSum prepared the animated visualization using existing-conditions data captured with its LD3 technology, which fuses point clouds, RGB and GPS data. “We wanted to use InteliSum for design as well,” Lindsey notes, “but we did not get them into this project early enough to use their data for design.” In other projects UDOT has used LD3 data to inform engineering – “InteliSum has done a survey for an intersection project, and we designed off that data,” Lindsey told us. “They’ve also done a railroad project for us.” UDOT uses LD3 “for survey, public hearings for projects, and media visualizations and demonstrations,” Lindsey continues. “Traditionally we would go out and collect survey points – the survey crew would probably go out two or three times before they got all the data we need. With the LD3 file, you pull it up and get all the data you want.”

The third enabler of Accelerated Bridge Construction is the construction management/general contractor (CM/GC) approach to contracting. With this, Lindsey explains, “We are not going for the low bid, but instead the most economic proposal – which will get the job done faster, at the highest quality.”

UDOT won a $1 million “Highways for Life” award from the Federal Highway Administration to help implement the ABC process, Lindsey reports. “For the last 50 years we’ve been using the same business model to build bridges. This is the only industry using same business model as 50 years ago. Why? We need to move forward.”