Earlier this month I had a long conversation with Certainty 3D CEO Ted Knaak about his company’s newest release of TopoDOT 4.2 . For the last two years Knaak has been on a mission to improve the quality of vector deliverables extracted from laser scan data and to shorten field collection times. TopoDOT 4.2 aims to deliver on the promise that laser scanning is more cost effective than conventional data collection, as much as 30% more cost effective. Of course the quality of the deliverable is better too.

Field Workflow is Key

What’s in the secret sauce? How can field collection times be reduced by 80% compared to conventional? The first step –no big surprise here- is to set up survey control in advance. Typically this takes two days to establish a control network for a mile of corridor in an urban environment and is completed before the scanning crew shows up. The next step is for the scanning crew to set up the initial reference targets for the first scan. These targets are used register the scans to each other which will in turn be tied to the control network. Then the scanning can begin. The reference targets for the subsequent scan position can be set up concurrently with scanning the current position. Knaak reports that checking the quality and alignment of the data before the scanner is moved to the next position is of utmost importance. Get collection right the first time and the back office savings are immense.

Today’s new scanners are very fast. The Riegl VZ400 collects data at 125,000 points per second which can drive scan times to a few minutes compared to nearly an hour per setup with older systems. Total time per setup can be driven to 10-12 minutes per position. This is a huge savings which translates directly into improved safety, reduced lane closures and less disruption to the traveling public.

Shifting the Burden to the Back Office

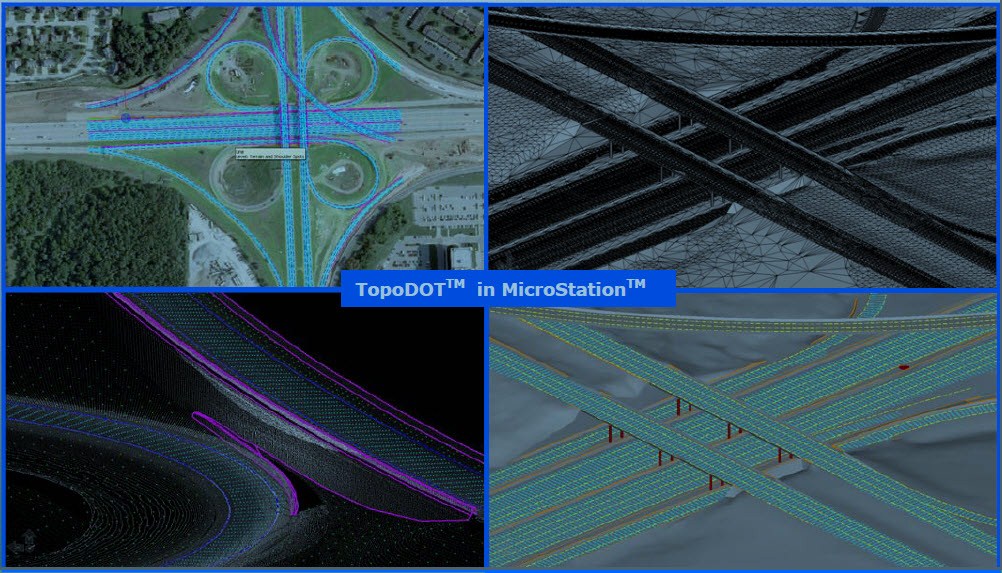

The magic of the TopoDOT-based workflow really happens back in the office. Today’s scanners produce huge data sets; the challenge is to extract useful deliverables in a timely way to match the requirements of DOT clients where the expectation is that they’ll get deliverables in less than a week. The solution according to Knaak is to partition the scan data and get the CAD operators working in parallel, a process that is only possible by starting with high quality data. TopoDOT enables multiple teams to extract breaklines, top-of-curb, back-of-curb, pavement centerlines and classify trees, canopies, manhole covers, fire hydrants and the like right inside MicroStation V8i. The Asset ID tool references MicroStation cell libraries for items such as height of tree and center of tree.

The TopoDOT engine maps CAD objects to point clouds to calibrated digital photographs in a perspective view which allows high operator throughput and accuracy. TopoDOT accepts data captured by static, mobile and airborne scanning systems and reads industry standard data formats such as LAS. Satellite imagery from Bing and Google can also be imported.

HNTB tested TopoDOT on a Kansas Highway Interchange I-435/SR69 project earlier this year and compared the results with their traditional Terrasolid method. According to Paul DiGiacobbe, Principal at HNTB, TopoDOT has the distinct advantage of not requiring the creation of an intermediate surface file, i.e. you can work directly with the LAS LIDAR file inside MicroStation. This saves time and disk space as the intermediate file can easily be as large as the original LIDAR file. DiGiacobbe also says that the software includes some great tools for automating the extraction of line work. The acid test — HNTB purchased an enterprise license.

Turning back office processing into a procedure executed by multiple operators in parallel gets the deliverable out the door on schedule. With this workflow, field collection times go way down, and back office processing effort increases. The net result is reduced total cost because field collection time is considerably more expensive than back office time. A top survey crew can keep as many as 3 or 4 CAD operators busy in the back office.

Licensing TopoDOT

Certainty 3D has a novel licensing model designed to maximize access to 3D data across all operations at a very reasonable cost. All licensing is web-based, thereby avoiding the cost and management issues associated with hardware keys. A single license costs a modest $2995 and is tied to a single workstation.

For larger organizations, Certainty 3D provides an enterprise license program which is a unique, flexible “user-day” account balance system. Load TopoDOT everywhere across the organization for the initial fee of $12,000. Certainty 3D monitors usage. Customers pay for useage at a rate of $12 per day to buy and $8 per day for maintenance and support after the first year.

Certainty 3D – the company

Ted Knaak, the founder of Certainty3D is a process guy. An electrical engineer by training, he’s driven to make scanning efficient for transportation engineering and construction organizations. Two years ago he founded Certainty 3D to develop software tools and work processes to improve field to finish productivity. You have to admire the approach: first, write code; then test code on real projects; then re-write code based on project experience; and iterate until efficiency targets are attained. He’s hired a team of young engineers and surveyors not bound by conventional thinking and driven them to find a better way. Growth in the laser scanning industry is propelled by the unflagging efforts of malcontents like Knaak.