How widespread is the use of laser scanning currently?

There are many factors influencing a continued rise in the demand for laser scanning. Its global value is estimated to double between 2013 and 2018, from $2.06 billion to $4.08 billion, according to this report by Market & Markets. The report description goes on to list the following sectors and their most commonly used devices:

- Aerospace and Defense: laser scanners and optical scanners

- Entertainment and Media: laser scanners and portable 3D scanners

- Medical and Healthcare: laser scanners and optical scanners

- Architecture and Engineering: structured light scanners and optical scanners

- Oil and Gas: laser scanners and optical scanners

- Energy and Power: portable 3D scanners and laser scanners

- Automotive and Transportation: short-range scanners and portable 3D scanners

- Manufacturing: portable 3D scanners and optical scanners

For the purpose of this article, it is architecture and engineering that I shall focus on because it is this sector that will arguably use BIM, my area of interest, the most. I would add 3D scanners to the devices used by architecture and engineering, as I rarely see anything except tripod-based terrestrial laser scanning used on buildings.

Many of us in the AEC arena know the great catalyst that BIM could be (and has been) for further laser scanning uptake. If you were working on scheme designs for a new building or retrofitting an existing building, then the norm would be to have a measured survey carried out to start.

If the design is to be carried out using BIM (especially to Level 2 as defined by the UK Government), then this should be based on a survey in 3D. What is currently the best way to capture a survey for BIM in 3D? Laser scanning, of course.

So now we have seen that BIM will drive an increase in laser scanning use in architecture and engineering, let’s take a closer look at the growth of BIM.

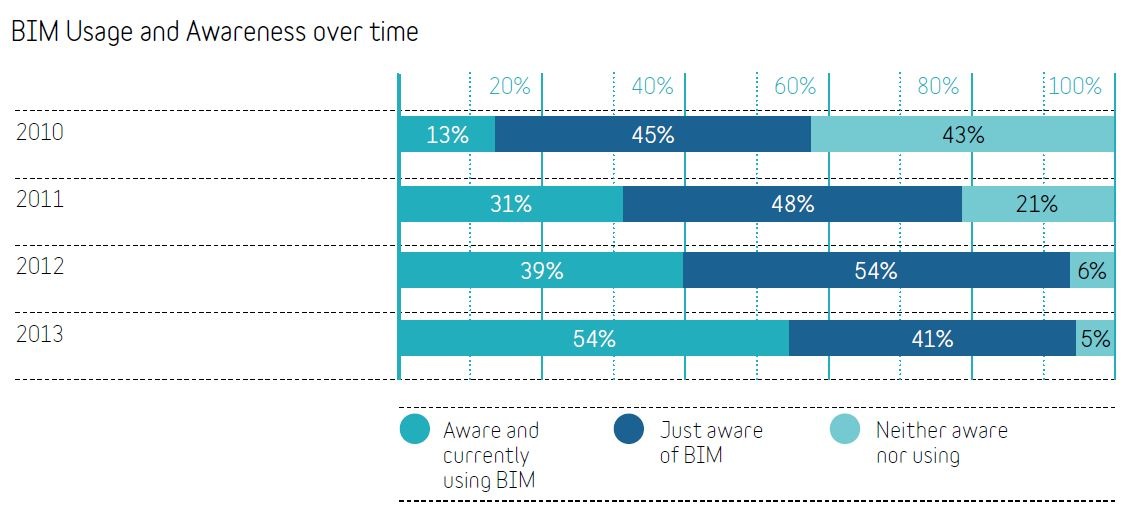

In the NBS National BIM Report (UK) 2014 , it can be seen that use of BIM has risen from 13% of respondents in 2010 to 54% in 2013.

Even with the number already using BIM in 2013, a massive 81% felt they would be using BIM in one year’s time, that number rising to 93% thinking they will be using it in 3 years’ time and 95% in 5 years’ time. Even if these survey results were treated with caution, it is clear that there is going to be a sharp increase in the use of BIM in the short to medium term.

With an increase in the use of BIM, this will have a knock-on effect and generate more requests for 3D surveys, resulting in more laser scanner use with point cloud deliverables. We can see that BIM, as it grows, will play a big part in the adoption of point clouds across non-survey disciplines.

As I sit at my desk writing this, I have just seen a timely tweet that perfectly demonstrates how BIM can help drive the adoption of laser scanning: New York-based BIM consultants Case Inc have just bought their first laser scanner.

If a leading BIM consultant such as Case Inc sees they can gain value and offer their clients a better service by purchasing a laser scanner and using point clouds, it’s highly likely that others will follow.

In a similar vein, every single session that I attended over four days at Autodesk University 2013 featured a point cloud. (It’s worth clarifying that I didn’t only choose classes about scanning or point clouds!) Simply, there appears to be an acceptance of scanning across the industry. I would go as far as to say that point clouds are expected even on projects completed by those outside of the 3D imaging and data capture profession.

This greater acceptance of point clouds in the AEC space is also leading to a greater use of the point cloud itself instead of a model derived from it. More and more design work is taking place straight against the point cloud instead of using a survey model or drawing. It’s becoming, simply, the way that people work. With such adoption, how long will “scan to BIM” survive? If it’s more efficient to design against a point cloud than against a survey-generated model, no savvy designer or client would go against the ethos of BIM and be wasteful in their process.

But what about after the design and delivery process?

As BIM will offer far greater information about a building/asset when it is handed over, clients will start to think in a different way as well.

Having an “as constructed” model with all appropriate information will enable a fantastic, data-rich starting point for the owner or operator. The smart operators/maintainers will use this as a basis to manage their assets in a way never before possible. With the right processes, people, and technology in place, laser scanning could offer great benefits.

Keeping an up-to-date Asset Information Model (AIM) is no small task. Though laser scanning is obvious as a tool for major works projects, it is the smaller, minor everyday maintenance tasks that will be key to reducing operation costs and helping to reduce carbon consumption in the future. I have no doubt that processes and scanning technologies capable of achieving this task seamlessly will be developed very soon, but there are not yet any that are efficient enough.

To try to put the enormity of keeping an up-to-date AIM into context, let’s imagine that London Underground has a full geospatial and information model of all of its infrastructure and assets. Every night there are hundreds or thousands of people working on maintenance tasks. How can every one of these be added to the AIM so that it is up to date and current? Recording what is new is the easy part, removing the old information and graphic elements and replacing them seamlessly with the new information is the hard part. This is our long-term ambition though, and through BIM and wider collaborative working I have no doubt we will get there.

.jpg.small.400x400.jpg)