.png)

Recent project involved five bridges for the Massachusetts DOT

BOSTON—Ten months after the purchase of a Leica Scan Station 2, Nitsch Engineering is deriving somewhere between five and 10 percent of surveying revenue from laser scanning, reports Paul LeBaron, senior project manager.

“We use it mostly to supplement current on the ground efforts,” he said. “We don’t try to spin it off into a separate piece of equipment.”

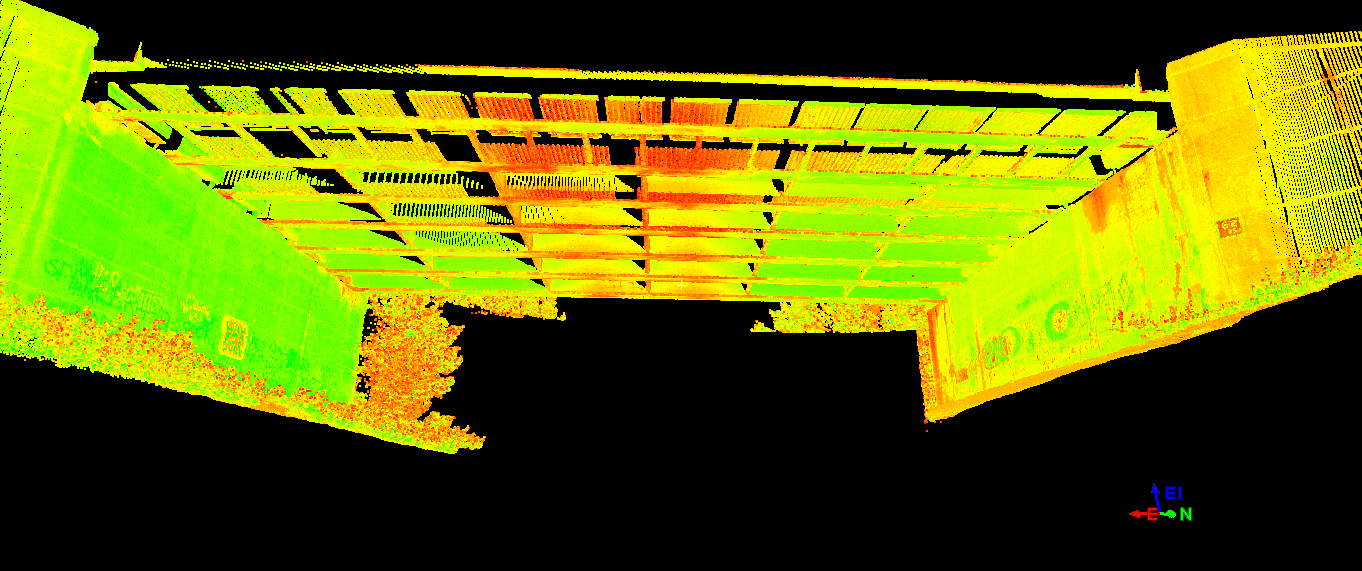

Laser scanning is definitely making the firm more efficient, however. Recently, Nitsch completed a job for the Massachusetts Department of Transportation, scanning five bridges in five different communities as part of a project to improve bridge crossings over CSX railways.

“It allowed us very safe access to the underside of the bridge,” LeBaron said of the laser scanner and how it was an improvement over traditional methods. “We didn’t have to send a crew member up on a ladder to pick up critical information. It allowed for very quick acquisition of the data that we were there to obtain.” Speed was important in this case as the large amoung of rail work being done at the time made it hard to acquire flag personnel to protect the surveyors.

LeBaron said each bridge took no more than two hours to scan, and the process resulted in far more information than was actually requested from the DOT. He estimated it would have taken as many as six hours per bridge just to collect the necessary information by traditional means.

Thus far, Nitsch Engineering has completed the laser scanning, processed the data, and prepared AutoCAD drawings for each bridge to show beam locations, bridge seats, batter of abutments and elevations on the underside of the structures. As the project moves forward, Nitsch Engineering will provide full support for project control, prepare easement and right-of-way alteration plans, and – upon completion of the bridge reconstruction – provide as-builts of the bridge structure, which will also include laser scanning.

While Nitsch could also provide some nice animation with all the data they’ve collected, LeBaron said he’s not interested right now in the wow factor that scanning can provide: “We try not to use the scanner as a gimmick. It’s just another piece of instrumentation that we have and pull out when it’s most appropriate.”

LeBaron called this a “smaller” job in the grand scheme of the scanner’s use so far. On the bigger end of things, for example, Nitsch scanned the interior and exterior of a million-square-foot building not long ago. He said Nitsch had completed roughly a dozen projects with the scanner, plus some quick gathering of points here and there on other jobs.

Currently, the 66-person firm has three people trained to operate the scanner, including LeBaron, but he said it’s the survey theory that’s important in learning to use the scanner properly, not the actual technical operation. “It’s still just survey,” he said. “You have to take the proper approaches, rather than just set up the laptop and hit the button … We do a lot of planning as to where we want our points, where to cut back and where to intensify shots, and that’s why we want senior people planning it out with our field scan technicians. I’ve told some of the guys on the field crews, ‘I can teach you how to functionally use it in about four hours, but you’re not going to get the information that I really want.’”