STANDISH, Mich. – Rail corridors have long been a target for airbone and other lidar service providers. “With rail being such a huge industry,” said Brian Bailey, geospatial services director at SurveyingSolutions, “of course it’s been targeted by everyone in the past.”

But maybe not in quite this way.

Surveying Solutions recently debuted RaLi, a purpose-built vehicle that can travel along railway lines, on the tracks, and provide mobile laser scanning. It’s what’s known as a “hi-rail” vehicle, which means it can travel on both normal roadways and train tracks (it’s a modified Ford F-350, actually), and Surveying Solutions has equipped it with a specially manufactured frame that allows the company to quickly and easily attach the same Riegl VMX-250-based mobile scanning solution it uses for normal roadway scanning.

“The beauty of the system,” Bailey said, “is that SSI was in Hawaii last week, rented a vehicle, attached the system and completed a project with mobile laser scanning. Then SSI turned around and shipped the system back out to Michigan, and it was on RaLi the next day.” Because of the purpose-built frame, it was a simple matter of unpacking, attaching, and quickly testing for any issues that might have been created by the shipping process (there weren’t any).

However, Bailey said, just because you’ve got a solution designed for rail doesn’t mean the business is there. “It’s hard to just go out there and talk theory,” he said. “You have to really have some substance behind your efforts.”

However, Bailey said, just because you’ve got a solution designed for rail doesn’t mean the business is there. “It’s hard to just go out there and talk theory,” he said. “You have to really have some substance behind your efforts.”

Sometimes, even that isn’t enough.

“We looked at this project we’re doing now,” Bailey said by way of example, “and the project team demonstrated to the rail company that it would take about 1,100 man hours to survey this conventionally, and we’re only asking for 16 hours of track time for RaLi. They said, ‘Can you do it in 12?’”

Bailey laughed. “We’re taking it from 1,100 man hours to 16 track hours and about 180 man hours total, and they still want it faster … It’s night and day, the advantages, but even that is not a shoe in. Track time is so precious that even when you show them it’s more efficient they still hem and haw. They really don’t want you on the track at all. It’s a constant battle. ”

That’s because track time is so valuable. And because track time is so valuable, you can’t do things the same way you do them on a highway. Think you missed something? Well, there’s no turning around to make sure.

“On the highway,” said Bailey, “if you lose GPS for more than a minute, you can just pull over. When you’re on a live track, there’s no stopping. You’re at the mercy of the dispatcher of the train company. That’s the world you live in.” Surveying Solutions had to develop a workflow full of redundancies and best practices that ensures the highest quality data is captured the first time through.

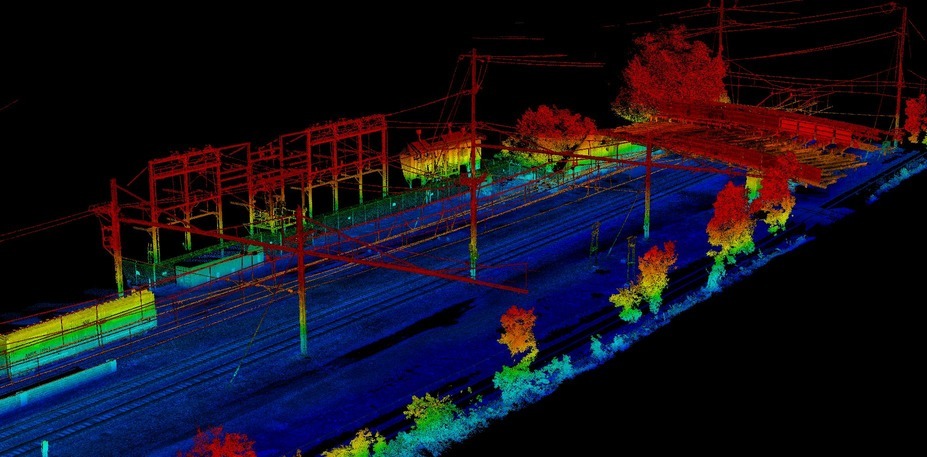

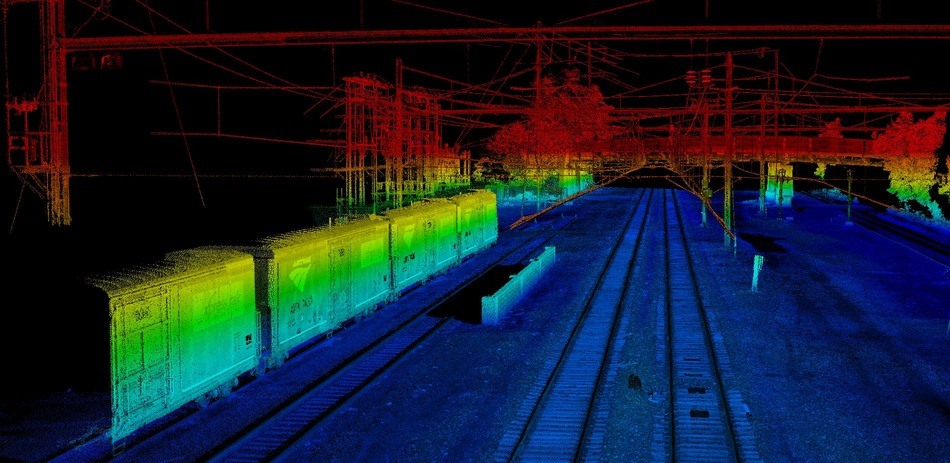

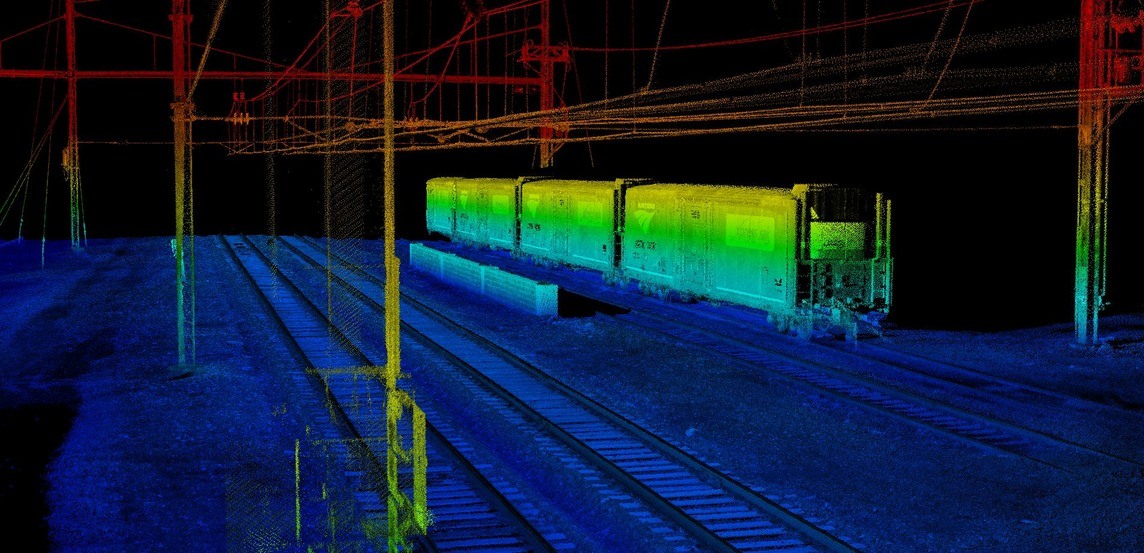

Here are some examples of the resultant data:

All of that said, fundamentally the system is set up the same way as the highway system, in terms of calibration and how the data is processed. Bailey said there’s about a 1:2 ratio between field time and back office time, just to get the data prepared to the point where you can extract the information the client’s looking for.

Say there’s a day of scanning. The first day in the office is for data crunching into an LAS file. Day two is for clean up. “Then we start extraction,” he said. Typical deliverables include digital terrain models, which might go pretty quickly, and the mapping of individual assets, which is more manual and time intensive.

Cracking the market in the first place took major effort, Bailey said, but now that he has an understanding of the marketplace, he’s seeing real potential for growth there. Down the line, it may even be that there’s enough business to dedicate the Riegl system to RaLi full time. “Traditional transportation work seems to be drying up a little bit,” he said of the necessity to explore new markets like rail. “Several states lost up to 40 percent of their survey budget, so we felt forced to look at different avenues. We can’t have a million dollar piece of equipment sitting in the garage.”

Sometimes, however, necessity is the mother of invention, and Bailey believes the techniques his team is developing will help to move the industry forward and lay groundwork for the rail industry to see value in laser scanning. Unfortunately, he said, he’s found some people in the business have had bad experiences with lidar projects in the past, and that makes the sales job that much harder.

“There have been people who have oversold and couldn’t deliver,” he said. As Surveying Solutions pushes into the industry with RaLi, that’s something of which Bailey is particularly cognizant.