After several successful fundraising rounds, it is clear that PreVu3D hopes to break into the digital twin space and encourage companies to create digital replicas of their in-person buildings and assets. Founded in 2017 by mechanical engineers looking to improve their own practices, the Montreal-based company has developed a software solution where users can create, edit and collaborate on 3D replicas of real-life environments.

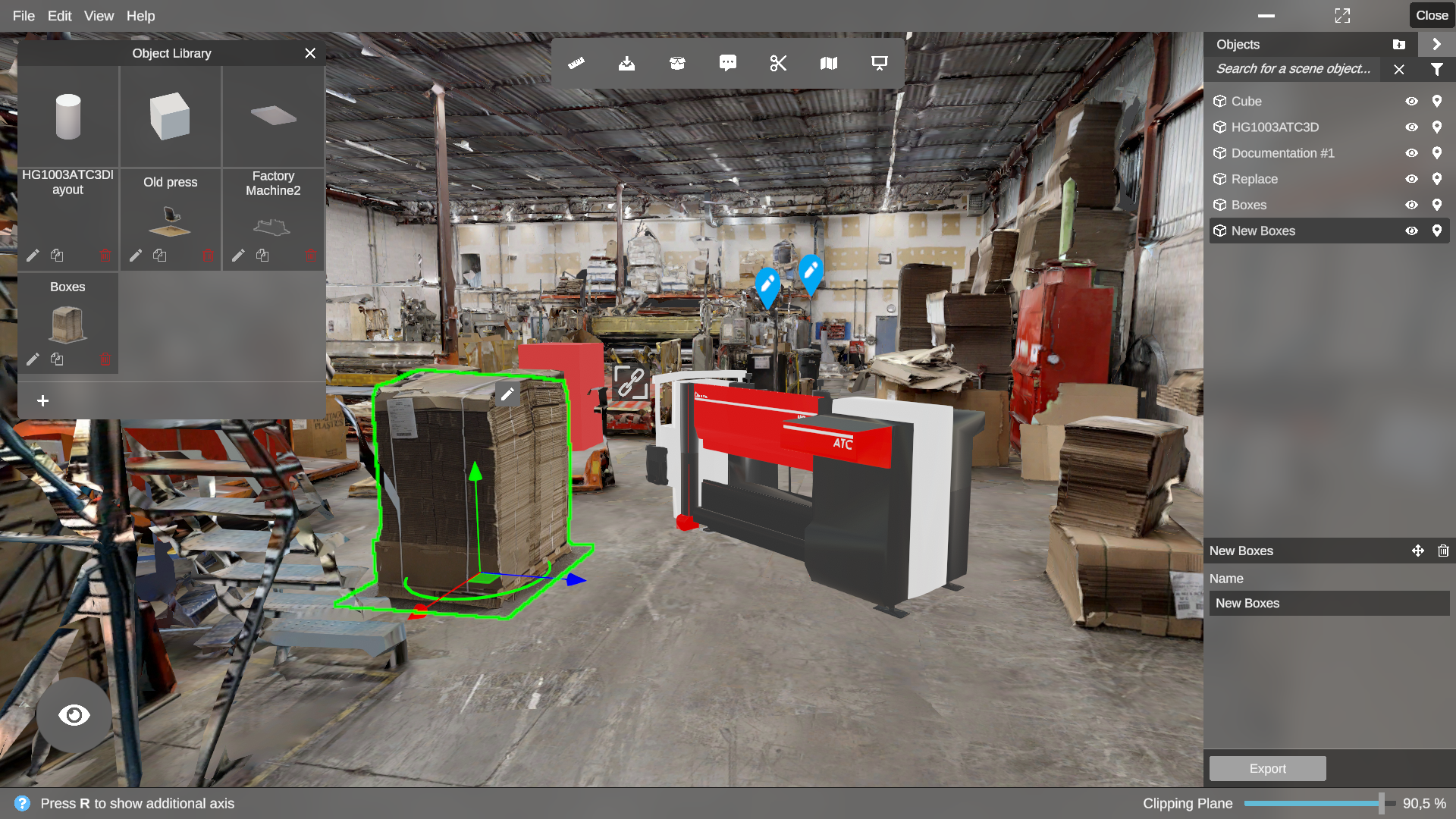

To date, nearly 40 million square feet of interior and exterior spaces have been processed and modeled on PreVu3D’s platform. The tool saw notable adoption in the manufacturing industry, for which it creates a precise and photorealistic 3D digital replica of a factory, allowing users to modify the space by adding, deleting or moving any element in just a few clicks. Built for ease-of-use, the software promises efficiency gains and cost savings in multiple use cases.

Last week, PreVu3D raised a seed round of $2.5M CAD ($1.8M USD) seed funding – bringing its total funding to $3.3M CAD. According to CEO Nicolas Morency, the financing couldn’t have come at a better time.

“COVID-19 is accelerating the need for businesses to interact with their physical spaces remotely or rethink their existing setups. The manufacturing industry is in the midst of a digital revolution (Industry 4.0) and this same phenomenon is happening across all sectors of the economy. Recent technological advances in 3D image capture now offer speed and quality, in addition to being affordable and available worldwide.”

PreVu3D has also announced a new ‘social distancing design tool’ that is intended to help companies to reconfigure their spaces to adhere to social distancing guidelines.

The base PreVu3D tool is set apart slightly from other similar tools in that it has been designed to be used to manipulate a combination of captured and modeled information – for example, allowing facility owners to model where new equipment might exist in real life by adding CAD or 3D models to a digital twin of a real environment. This type of modeling may enable easier planning for facility renovations and expansions.

In anticipation of the growth of the use of digital twins, Morency predicts that they will be leaders in getting people to adopt digital twins across many industries.

“PreVu3D is democratizing this type of solution by making interactive 3D spaces accessible to everyone via our automated platform – across all industries and devices. The market for digital twins will increase tenfold within five years. With this new funding, I believe we can be a major player spearheading this growth.”