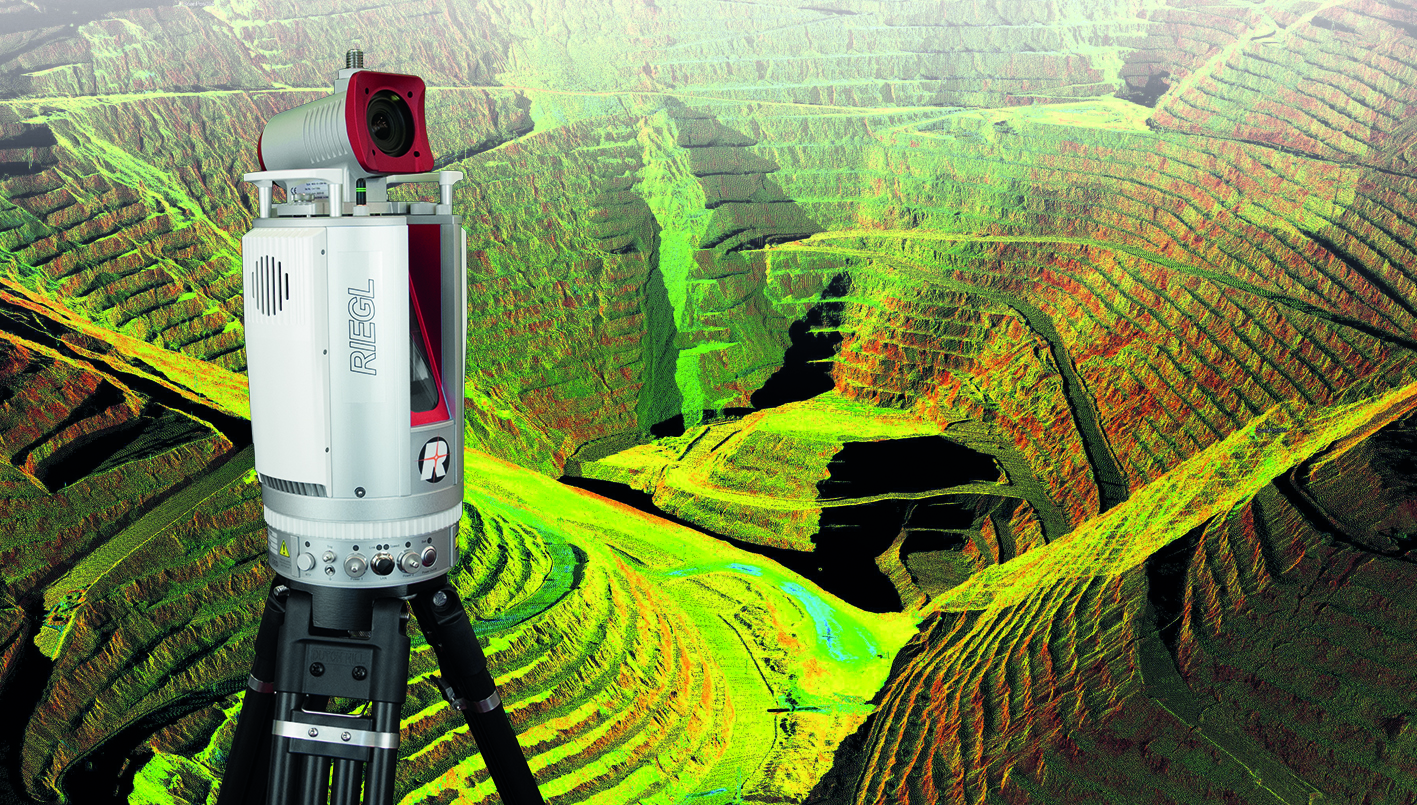

RIEGL’s 3D terrestrial laser scanners can already be integrated easily in network infrastructures, which enables remote operation of the scanners. With three new apps, real-time scanning data is provided to the user without any form of user interaction, enabling faster and better business decisions onsite. By sharing information quickly onsite with different stakeholders, they can quickly visualize important 3D data in the field, while being away from the scanner.

These apps provide local slope angle calculations and visualizations, undercut and overcut visualizations and differences to a reference data set. The 3D data visualizations of each app are made visible to the user via a web viewer, that has been optimized for Mozilla Firefox, Google Chrome and Microsoft Edge. The web viewer is available on the scanner via LAN, WLAN and mobile. In total, there following three new apps have been released, which are all targeted at RIEGL VZ-i series of 3D terrestrial laser scanners:

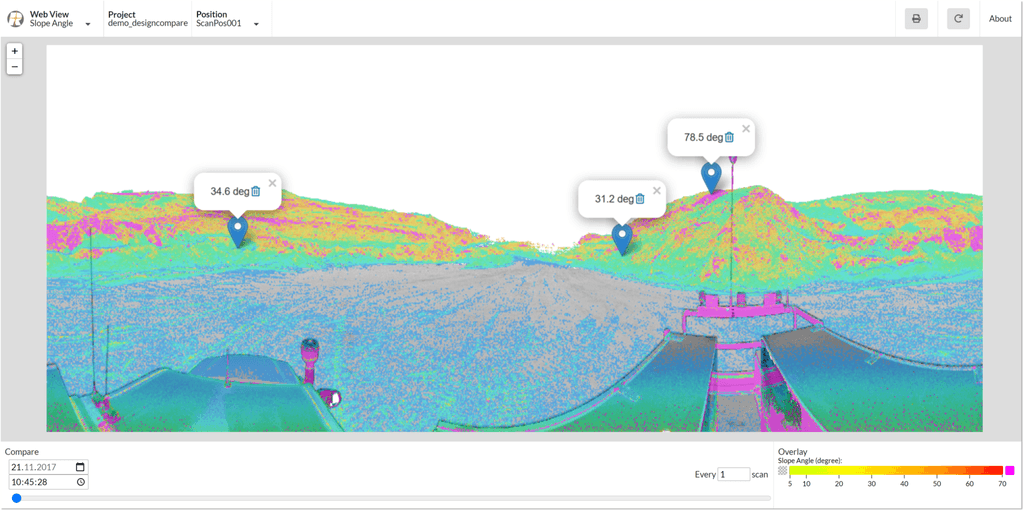

Slope Angle app

This app calculates slope angles automatically from scan data. Critical slope angles can be highlighted and sent to the user, such as the operator of loaders. The real-time information helps them to keep the slope angles of stockpiles and dump areas within the defined limits. They receive the information on a web browser on every device, which is connected to the mine network. No software installation or processing of the data is necessary: everything is processed automatically within the app on the scanner.

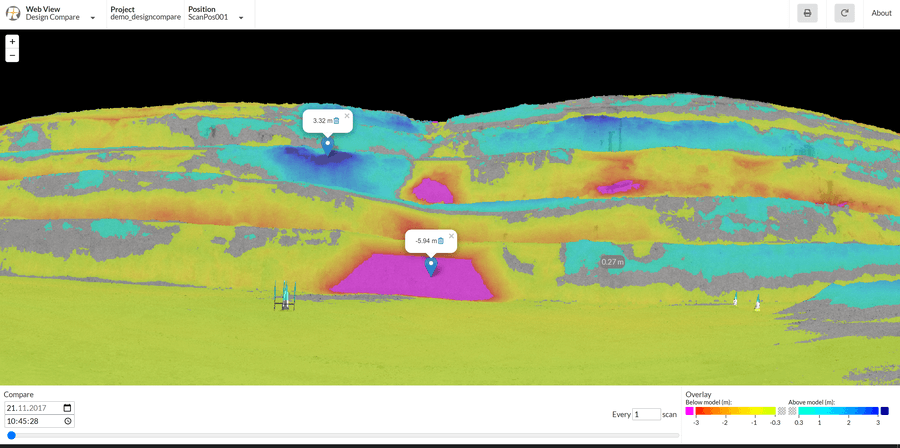

Design Compare app

This app creates a data comparison to a given 3D design model, visualization of undercut and overcut to support machine operation. While undercut is a waste of money, overcut can involves major safety risks. With the use of this app, the operation of heavy equipment such as digging machines can be optimized to streamline the mining process.

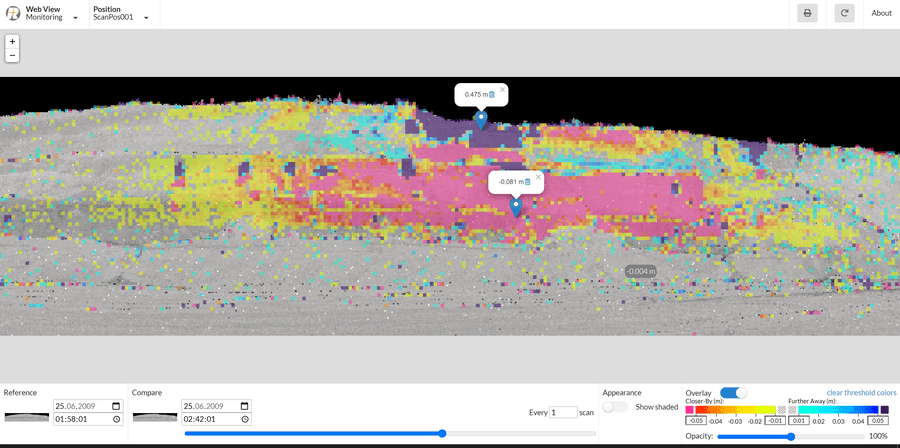

Monitoring app

This app calculates change detection to a given reference scan, which allows for example to detect movements of highwalls long before it is visible to the human eye. The interpretation of the movements through a time series of scans allows the prediction of a possible slope failure, which can truly save lives, ensuring that there’s enough time to evacuate people and remove machinery from the endangered areas.

Every app guides the user through all the relevant settings using a wizard, that lists the project settings using a project name and storage location. The monitoring app requires a definition of a proper scan pattern in the monitoring settings, as well as a definition of a proper data acquisition scheduling. The app’s change detection settings require a definition of proper threshold, and here the user can define proper tables and colors. The DesignCompare app requires the user to define a set of design compare settings, including the reference design model, a coordinate reference system and proper threshold values. Finally, the SlopeAngle app adds Slope Coloring settings, defining a proper threshold and colors.

In addition to the release of these three apps, RIEGL has further optimized their software packages RiSCAN PRO and RiMINING. The new LIS GeoTec Plugin enables geotechnical analysis of scan data by providing statistical tools within an easy-to-use graphical interface. Besides the calculation of dip-direction and dip-angle of rock faces, it allows for the analysis of discontinuities by creating pole-plots and colorizing the scan-data by clusters of similar orientation. This gives specialists a better understanding of stability, joints, and faults of the analyzed rock faces.