Alberta Transportation retained Stewart, Weir & Co. Ltd. in the summer of 2002 to provide engineering and surveying services for the realignment of a portion of Highway 627. The highway runs through the site of the Highvale Coal Mine, an open-pit mine owned and operated by TransAltaEnergy Corporation.

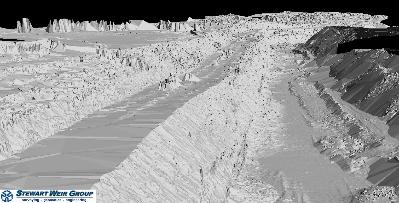

According to Garry Bondarevich, manager of 3D laser scanning with Stewart, Weir, “The problem that was facing our firm was how to safely and accurately survey a large ditch that was over 1.3 kilometers in length, is close to 150 meters in width, and contains severe terrain restrictions.”

Bondarevich reports that the need for his firm’s services arose because the highway had been built over a rich bed of coal, and was hampering mining operations. To remedy this, the project was undertaken to realign the east-west highway to the north in an area that had been previously

mined. This would allow expansion of the mine to the south, and mining of the coal under the existing highway right-of-way.

Technical and safety considerations made traditional survey methods unattractive

In the area of the mine planned for the new highway alignment, the coal had been removed, and a large ditch was left behind. More than 40 meters deep, the ditch consisted of cliffs and steep slopes of loose

native material. To perform a detailed engineering design of the highway realignment and calculate earthwork quantities, a survey was required after loose material was removed and before the start of construction.

Both technical and safety considerations made traditional surveying methods unattractive. “To perform the survey manually would require personnel trained in the proper use of climbing equipment to rappel

down the cliffs with ropes and perform the survey of the ditch,” according to Bondarevich. “Reflectorless total stations were considered, but due to the available equipment setup locations, the large scale of the project, and construction activities, it was not considered safe or feasible.”With laser scanning, a two-person crew completed the topographic survey in one day

The solution chosen by Stewart, Weir was to use the ILRIS-3D laser scanner from Optech Incorporated to collect point-cloud information on the entire survey area. A two-man crew was used for targeting and operation of the laser scanner as it was positioned at prime locations along the ditch and overlapping scans were obtained.

Survey control coordinates were supplied by GPS and total station equipment, which was operated by a survey crew that was on site for the overall construction of the highway. In just one day, Stewart, Weir reports, the laser scanning survey crew was able to execute an accurate and complete topographic survey of the area without endangering personnel.

After the survey was complete, scan information was processed using the PolyWorks software from InnovMetric Software Inc. to align (register) multiple scans into one overall dataset, and to georeference the survey information to the project coordinate system. Once this was complete, a

grid that accurately represented the surface of the ground was generated from the complete laser scan dataset.Work process issues: survey control, accuracy and detail

A critical issue in projects of this kind is survey control, according to Bondarevich. “You have to make sure you have good survey control, so the information you collect on the ground is accurate.” To ensure that all scan setups are correct, he reports, “Proper survey practices are crucial. Use of proper survey discipline in the field is important, even with laser scanning.”

Another work process issue is the need to consider the project’s requirements in advance of scanning, “and plan your survey accordingly.” In particular, Bondarevich advises, the data captured in

scanning “has to be something that has the accuracy and level of detail you need.” How the data will be used has to be “thought out in advance. Proper planning of the survey is essential to getting the required results.”

After scanning is complete, processing the data can also pose some challenges. “If the scene includes bushes or other features that you don’t want to capture, they have to be stripped out in the data processing phase,” Bondarevich notes. “We were fortunate in this case not to have vegetation, but in some jobs we had to remove it.” However, in this job, he notes, “there were vehicles in the way, which we removed during processing.” This was done prior to the process of creating the digital terrain model of the site. “You can have the DTM application span across those open areas, by setting criteria in the DTM software appropriately,” he explains. Alternately, “you can fill in the gaps using PolyWorks.”

Scan data was georeferenced and used to generate a ground-surface grid

Laser scan data was aligned (registered) and then georeferenced to the project coordinate system using the PolyWorks software from InnovMetric, which Optech offers with the ILRIS-3D scanner.

Next, PolyWorks was used to generate a grid representation of the ground surface from the scan data. Stewart, Weir explains that this is done to reduce the number of data points to a size acceptable and

manageable by downstream engineering software, while maintaining the required level of detail in the ground surface data.

The grid representation was exported from PolyWorks to an ASCII file containing xyz coordinates. The resulting file was then imported into CAiCE, from the CAiCE Transportation Group of Autodesk, Inc., to do the earthworks calculations.

Data completeness, accuracy, and worker safety were key business values of laser scanning

Completeness and accuracy of the data generated in laser scanning were key business values for Stewart, Weir. “The results were outstanding,” Bondarevich reports, “and provided our highway engineering department with complete and reliable survey data for their engineering computations.”

An equally important benefit for the firm is safety. In Bondarevich’s view, the project “has also shown others in the industry that the correct application of laser scanning technology on even the most difficult

projects can obtain survey information quickly, accurately, and above all, safely.”