Last month, Maptek I-SiTE announced its entrance into the Indian mining market with the sale of its I-Site 4400LR scanner to GULF OIL Corporation Ltd. of India. The IDLconsult division of the Hyderabad-based company bought the time-of-flight laser-scanning unit with its accompanying I-SiTE Studio software to mine coal, iron ore and limestone, and to monitor civil construction projects, including road and railway bridges. From an Internet-friendly grass hut, Jude Fernando of IDLconsult explained the motive behind the purchase: “In the process of scaling up our mining operations, we needed to enhance our operations planning and monitoring wing. We needed a quick way to visualize (through a bird’s-eye view of) our mining operations for better monitoring and control.”

Fernando says his group has undertaken scanning operations in its existing mining operation, which has enhanced operational plans by understanding the 3D topography. “The 3D surface rendering of the topography gives valuable information and pictures to understand operational and safety requirements.”

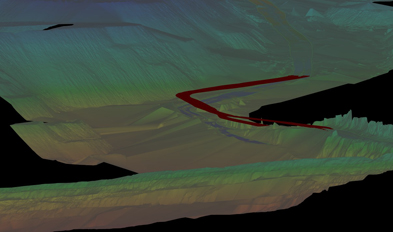

Fernando points out many specific advantages of the scanning unit, including its benefit in safety and team collaboration. “… as a corporate industry, we aim for the safety of our men [and]machines… The picture of the mine operations are continually before us to think about the betterment of the operations,” he says. “The optimization of the haul road profile in one of our mines [see Figure 1]will enhance productivity along with better safety for the operators and the equipment.”

He continues: “The laser scanner has made survey more interesting, fast and accurate. The additional facility is the software that helps the visualization. We are able to actively collaborate with operational staff. The references of discussions are becoming more focused, and as a result, we feel [that]the team bond between managers and the executioners has greatly grown.”

Steven Wong, Maptek’s global business development manager, says the unit will be less time-consuming than total station data collection and provide more accuracy in IDLconsult’s volumetric calculations of earth moved, filled and removed. Additionally, it will benefit high-wall mapping efforts. “[They’ll be able] to see clearly from our scanner that has a 37-megapixel camera built into it, which means they can render the digital imagery on top of the scan points,” Wong says. “In essence, it’s being able to measure a photograph in 3D. Geologists will love it because they can see the high wall clearly. They can then calculate the volume of the seam on the high wall.

“Before scanners, they used total stations only two or three or four feet away,” he continues. “Instead of collecting hundreds of points, they’re [now]collecting millions of points [and]have a variance factor of ten to fifteen percent of a pile of very expensive material down to less than two-percent variance. That’s big savings.”

Fernando adds, “The huge reduction in the number of manual readings is a sure candidate to expose the superiority of this technology. The visualization of the surfaces and the accurate sectioning of the mine area is a great advantage over manual data handling.”

IDLconsult handles about 5 million cubic meters of material per month in the mines it services. By mid-September, the group had scanned three of its major operations (more than 60 scans) with plans to scan the topography of another. According to Fernando, IDLconsult predicts that it will take in another scanning unit in the near future.