.jpg) Project success in revamping facilities used to store, process or generate electrical power from nuclear material requires safe, accurate and fast capture of dimensional information. Laser scanning is proving

Project success in revamping facilities used to store, process or generate electrical power from nuclear material requires safe, accurate and fast capture of dimensional information. Laser scanning is proving

itself capable of delivering these values.One year ago the Department of Energy announced it awarded a $128 million, nine-year contract to Isotek Systems LLC, Oak Ridge, TN, to down-blend 1.5 tons (metric) of its stores of enriched uranium-233 and render isotopes such as thorium-229 from which can be extracted isotopes useful for treating cancer. (Isotek is a limited liability company owned by Duratek Federal Services, Inc., Nuclear Fuel Services, Inc., andBurns and Roe Enterprises, Inc.) For safety and security reasons, uranium-233 is expensive for the Department of Energy to store – down-blending results in products that are not only useful medically, they’re also of little value on the nuclear black market.

On Friday last, we interviewed some members of the team from Burns and Roe that used laser scanning to capture the existing conditions for Building 3019A at Oak Ridge National Laboratory, Oak Ridge, TN, the facility that will be revamped for the down-blending.

Motivation for laser scanning: accuracy, minimizing exposure, security, controlling scope changes

Burns and Roe was motivated to use laser scanning to document the existing conditions of the facility where the material is stored for several reasons. Foremost was the requirement for accuracy. Building 3019A was used as long ago as the Manhattan Project in the 1940s; after years of modifications – some documented, others incompletely or not at all – the paper drawings of the facility were judged to be inadequate. For example, in one area the team discovered an undocumented six-inch slab, which is scheduled for removal as part of the demolition to allow subsequent equipment installation. Another room was found to be off by 2 feet in one direction and 1 foot in the other. Laser scanning brings the

benefit of being able to quickly locate such errors from the safety of the office desktop.

Some of the rooms in Building 3019A contain high levels of radioactive contamination. The first principle of limiting radiation exposure is to maximize the distance from the source. Here laser scanning is superior to manual data acquisition because the data can be captured at a distance. Fast data acquisition is also possible using laser scanning, which also means less exposure to harmful radiation.

According to project manager Norm Lacy, security concerns also drove the decision to use laser scanning on this project. The data could be captured with fewer people in fewer shifts, which meant fewer security clearances to arrange.

Project managers from a variety of industries have pointed out to us that a collateral benefit of using laser scanning is being able to control scope changes and creep. Burns and Roe’s Robert Nicholas, who escorted the scanning team, notes that the team scanned more rooms than they originally had planned, that the information proved to be useful, and that it saved revisiting the site to capture the needed data.

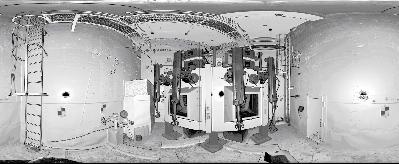

“Project-hardened” work process from BitWyse

Scanning of the 30,000-sq- ft facility, which took place over four days in March 2004, was executed by 3DS2, Inc., Elkhorn, NE, using a Z+Fscanner. Some twenty rooms of the facility as well as parts of the outside of the building and roof were scanned, resulting in 105, 360- x 270-degree, high-resolution scans, with 256 million points in each. The individual scans were registered inBitWyse’s SceneManager™ and then merged in BitWyse’s LASERGen design models. Bentley MicroStation models were produced using LASERGen to inform the revamp design. Intergraph’s PDS was used for the piping and equipment with the LASERGen models referenced in the background, providing the PDS user with all the existing conditions data for each cell. Burns and Roe was a beta site for BitWyse’s Project Notebook Lite, which it used to manage scan and model data for project review purposes, allowing all users, event those without 3D experience, access to the existing conditions data.

According to Burns and Roe PDS manager Vlad Savulian, BitWyse’s support personnel took an active role in the post-processing of the scan data, which contributed significantly to the project success. According to BitWyse CEO Mark Klusza, “Successful laser scanning requires a project-hardened work process: some of the elements are registration of the scan data – often hundreds of scans, verification of the data, integration with design models, interference detection and management, and viewing the data by non-CAD professionals.” Using a work process developed by BitWyse, the Burns and Roe team reports it was able to quickly implement its first project.

Project impact at DOE

This DOE project was the first time Burns and Roe used laser scanning. The company has a reputation for researching and carefully selecting new technologies that improve project performance. According to Wayne Uffleman, director of information technology at Burns and Roe, six years ago the company had used models based on photogrammetry, but was disappointed by the level of accuracy and completeness of the result. Design work for the DOE project is currently 60% complete – demolition

and construction are scheduled for the end of 2005. When we asked the team if they would use laser scanning again, the answer was a clear yes. For revamp work where it’s difficult or unsafe to capture the data with manual methods or where there is significant project complexity, then the case to use it is very clear.

According to Uffleman, the software leasing costs are also a consideration, and it has to make economic sense to justify the investment. The Burns and Roe team agrees that the biggest obstacle to

getting the technology more widely used is convincing the company’s project managers that it works and that it delivers cost and schedule savings. Project manager Norm Lacy, who’s been with Burns and Roe for thirty years, says he wishes he’d been able to use laser scanning on some of his previous nuclear decommissioning projects where accurate dimensional information was needed and where you’re “always trying to reduce exposure and put distance between you and something that’s not good for you.”

What’s needed going forward?

Burns and Roe project team members cautioned that more development work remains to be done to make the use of laser scanning collection work processes even more effective. Shadows, i.e., areas not seen by the laser scanner, can be difficult and pose interpretation problems. The tradeoff has to be made between capturing more scan data to reduce the shadowed volume and managing more data at the back end. Here’s where having a digital photograph to augment the scan can help. Color photos would be even better, as some of the piping is already color-coded.

Being able to clip the data with arbitrary clipping planes to help resolve ambiguities about which voxels are selected for measurements would also be useful. The issue here is that unlike ideal orthogonal CAD geometry, as-built conditions are rarely plumb and level. [We understand this capability has now been implemented in LASERGen – Editor.]

Savulian also observed that there is an up-front training burden to be absorbed to get CAD operators fully proficient with using laser scanning in a MicroStation environment to get unambiguous measurements. The team would also like to see more capability to print better-quality, higher-

resolution images of combined scan and CAD geometry