ClearEdge takes a ‘pretty major leap forward’ with EdgeWise Plant 2.0

HERNDON, Va. – In the realm of automated feature extraction from point clouds, software maker ClearEdge thinks it has the jump on the competition with the brand-new EdgeWise Plant 2.0, released today for trial download. Among the improvements over 1.0: Users can move from processing a dozen or so scans at once to processing thousands of scans at once; a marked improvement in number of pipes recognized; plug-ins with AutoCAD and Microstation; and a streamlined user interface that ought to make the software more useable for more people.

“It’s a pretty major leap forward in terms of processing and the amount of pipes it can extract,” said Chris Scotton, ClearEdge president and CEO.

Founded in 2006 by CTO Kevin Williams, after his time working for the Department of Defense, ClearEdge released its first product, EdgeWise Building in 2009, then released its Plant product in March 2011.

While Plant 1.0 was well received for the amount of busy-work it could eliminate, said Williams, “when working with oil and gas guys, for example, some of them had thousands and thousands of scans. But the 1.0 version could process up to five or 10 scans at once; it was very limited in the size of project. And that was a stumbling block. They loved the technology, but they needed to deal with larger data sets. So that’s where the bulk of the effort was for 2.0 – being able to work with unlimited amounts of points in each scan, and then virtually unlimited numbers of scans.”

“It’s now applicable to really large projects,” he said. Thousands of laser scans can be batch-loaded and left to process overnight or over the weekend, with periodic saves of the processing completed automatically, so that work won’t be lost even if there’s a loss of power or some other disturbance.

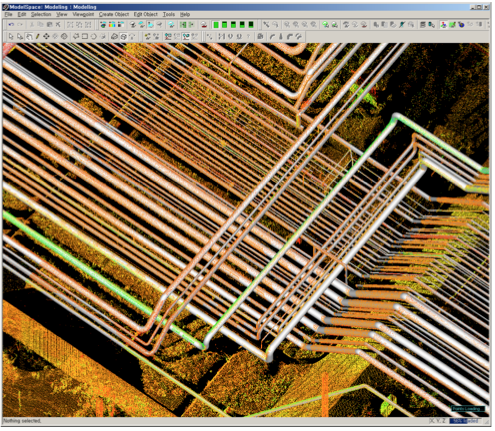

In a demonstration provided to this reporter, EdgeWise Plant 2.0 stood out for its simple user interface layout, very quick workflow from uploading scans to actual modeling, and for an impressive refresh rate and display of large point clouds (even via WebX).

With 2.0, ClearEdge also unveils a new pricing structure that allows companies to pay for the software by the number of scans processed. While the “Unlimited” price will be $7,995, firms will be able to purchase 25 scans for the lowest price of $995. The price-per-scan decreases with bulk purchase, until “the price per scan comes down to four or five bucks per scan,” Scotton said. Further, everyone with licenses for 1.0 will automatically get a free upgrade to 2.0.

At the heart of all the improvements is efficiency, helping survey and engineering firms increase their margins and lower their costs as they tackle scanning-intensive jobs.

“The time savings are just so dramatic,” said Williams, and ClearEdge has gathered impressive quotes from the 2.0 beta testers. Kevin Grover at Stantec said the company was able to “reduce 3D modeling time by 50 percent.” Nick Bobbit at 3D Imaging Services was able to complete a project “in only 55 percent of our original process time.” Jody Lounsbury, HDS manager at Clough Harbour & Associates, talked about a four-hour piece of work being reduced to 10 minutes.

These are significant time savings.

“Computer vision is only for the simplest of features,” Williams said, frankly. “There’s still plenty of room for them to apply their brain power and figure out the nuances and where there’s insulation on the pipes and things like that where the software has no idea. Computers are never going to replace human intelligence. They’re just not.

“But there’s some stuff that’s just grunt work, and that stuff should be automated,” he continued. “People have better things to do than just find simple, easy, repetitive things. We’re taking the tedium out of the modeling process.”

Hopefully, ClearEdge is taking some of the frustration out of the process as well, not only by offering plug ins to Microstation and AutoCAD, which will allow people to pull modeling data directly into those programs so that they can continue work, but also exporting (either directly or through the Model Import Utility) in a wide range of data formats, including DWG, DXF, ACIS, SAT, and COE, as well as taking data from laser scanners from FARO, Leica, Reigl, Surphaser, Topcon, Trimble (the FX), and Z+F.

As middleware, said Williams, “our strategy is that we want to do automated feature extraction really, really well, and that should be a button click.” ClearEdge knows that “automated stuff is never going to get 100 percent of the way to the finished product,” and “other people do the additional work extremely well,” like Microstation and Open Plant and AutoCAD,” so the company wants to be a plug in and a complement to those larger and more complicated packages.

Even a companies like kubit or LFM, they said, are more partner than competitor, despite their advances recently in automated feature extraction. Both packages, they said, offer far more features than EdgeWise Plant 2.0. “They do a lot more than we do,” said Scotton. “And that’s good, we’re not trying to do what they’re doing.”

That ought to be good news to scanning service providers, engineering firms, and asset owners with internal scanning departments who have been struggling with the man-hour-intensive task of creating as-built models from scan data. The kind of time-efficiencies the beta testers are espousing, and that become quickly obvious upon demonstration, are likely to help grow the overall market as more value can be extracted from scan data at less cost. It should mean that more scanners are in use more often, more firms are willing to make the leap into scanning, and that there will be less project cost eaten up by back-office expense.