FLORENCE, S.C. – As a new laser scanning service provider just starting out, Clarity Scanning could use something to set them apart from the crowd. How does a lidar-to-print service grab you?

Thad Wester, Clarity’s founder, is giving it a go. “The only real advantage we bring,” Wester said, “is that I’ve got a unique background having played with scanners for the last four or five years, just messing around with them to learn their ins and outs.” As both an undergrad and graduate student in Geography at East Carolina University, Wester had plenty of time to explore possibilities, and that led him to an artist in Michigan who wanted to print out digital elevation models.

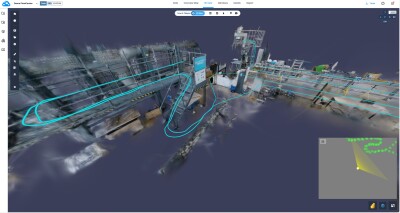

His investigation there – getting the workflow down took him three or four months – led to Clarity’s current business offering. Have you got a point cloud? Webster can print it out. Doesn’t matter what format it’s in.

Which is harder than it sounds. “The devil is in the details,” Wester said. “We’re meshing the points, but when you print something it has to have a thickness, that’s the crucial thing. So, we’re taking any kind of point cloud, adding a thickness, and then it’s printable.”

Currently, it can take three or four pieces of software to get from point A to point B, but Webster has some hope that recent developments like 3D Systems’ purchase of Rapidform and Geomagic might make things easier on that front. “Maybe a ‘print’ button in Geomagic,” he offers. Nor are those sub-$2,000 printers quite the solution.

Wester currently uses Shapeways for his print fulfillment. “The first time I got the 3D print back, I was fascinated, just blown away, like, this is the coolest thing ever,” he said, “and I was going to buy a 3D printer, but the artist I was working with said, ‘I already tried that, you can’t print the meshes on the cheap low-end printers; you need one of the million dollar jobs for that.’ It looks like the low-end ones aren’t quite there yet for processing these huge files.”

Some of the software is lagging, too, he said. “On one side, you have all the scanning software, like Cyclone can handle million of points, but when you want to put it into 3D printing software that’s used to hundreds of points, things fall apart,” he said. “Especially when you get into an organic structure, like trees and bushes, it becomes difficult to print.”

As for the target market, Wester is working on that. There could be interest from site planners or architects who’d like a print out of a site location as it stands before design begins. And then there is the forensic marketplace. “When you print from the point cloud, you get the dirty features,” he said. “You don’t get the same print you get from a model. No one made it pretty, so you get all the dirty details … If you can print out the scene and hand it to the jurors, it might really make an impact.”