AVEVA says scan data of ‘as-operating’ vessel cuts costs, time out of service for refits, conversions

The global shipbuilding industry is reeling from the impacts of a sputtering economy and global overcapacity. New orders have virtually dried up and the persistent credit crunch is restricting access to loans, squeezing shipbuilders further.

Given the state of the industry, many expect a future surge of demand for ship repair, conversion and refit projects. One company following this trend is AVEVA Group plc, a 3D software developer for capital engineering projects in the process plant, power and marine industries.

The Cambridge, U.K.-based company just released a white paper describing how 3D laser scanning, design, and modeling generates big time and cost savings for shipyards and shipowners considering vessel repair, refit and modification projects.

“In a depressed, buyers’ market, shipowners are driving hard bargains and shipyard profitability is being squeezed,” said Gary Farrow, vice president of Aveva’s 3D Data Capture Business Management department. “Traditional manual surveying is costly, time-consuming and of limited accuracy. Dramatic increases in efficiency have been enabled through greater automation, rapid visualization and processing of laser data making the conversion of laser scans into 3D quicker and cheaper than ever before.”

The white paper, titled “On the Beam: How 3D laser scanning technology brings new opportunities in ship refitting and conversion,” said to cut drydock time, the “as-operating” vessel is laser scanned prior to arriving at the repair yard.

The scan data is captured directly into the 3D design environment. Once the scan data has been processed into an “as-operating” 3D model, the repair yard’s planners and designers can prepare accurate estimates of the work required.

When the vessel arrives, the refit design, materials procurement and fabrication work can already be completed, minimizing time out of service.

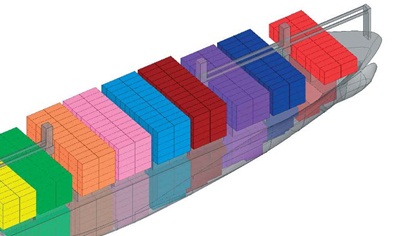

AVEVA’s shipbuilding design software AVEVA Marine allows users to visually compare 3D models of new equipment items and their associated pipe and cable routes through an engine room with an accurate 3D representation of the vessel’s existing structure and equipment in that room.

The software’s clash-detection functions detect any intersections of the new 3D models with the laser scanned model; for example, where a newly modeled pipe is being routed among existing pipes or bulkheads.

This allows for new steel structure, pipes, ventilation or cableways to be designed and fabricated before the vessel’s arrival in the repair yard.

One major refit project is called “jumboization,” which involves splitting the hull, separating the two halves and accurately inserting a newly manufactured hull block, usually with at least some of its outfitting items already installed.

AVEVA reports strong FY2013 results

In May, AVEVA reported record revenue for FY2013 of $344.5 million (£220.2 million), a 12 percent increase over the previous year, and profit for the year ended March 31 of $71.1 million (£45.5 million), a 13 percent increase over last year.

Total annual revenue from end-user markets included:

- Oil & Gas: 45-50 percent

- Marine: 20-25 percent

- Power: 15 percent

- Other (Mining, Petrochemical, Chemical and Paper and Pulp): 10-20 percent

AVEVA uses a subscription-based license business model, meaning EPC (engineering, procurement, and construction) customers pay a fee for ongoing access to its software.