AVEVA software helps keep construction on budget, on schedule for commissioning by end of 2013

When Brazil-based engineering contractor Promon Engenharia was hired to produce engineering designs and construction management for the country’s first vanadium pentoxide plant, it needed a strategy to boost project efficiency by shortening schedules, lowering costs and improving the quality of deliverables.

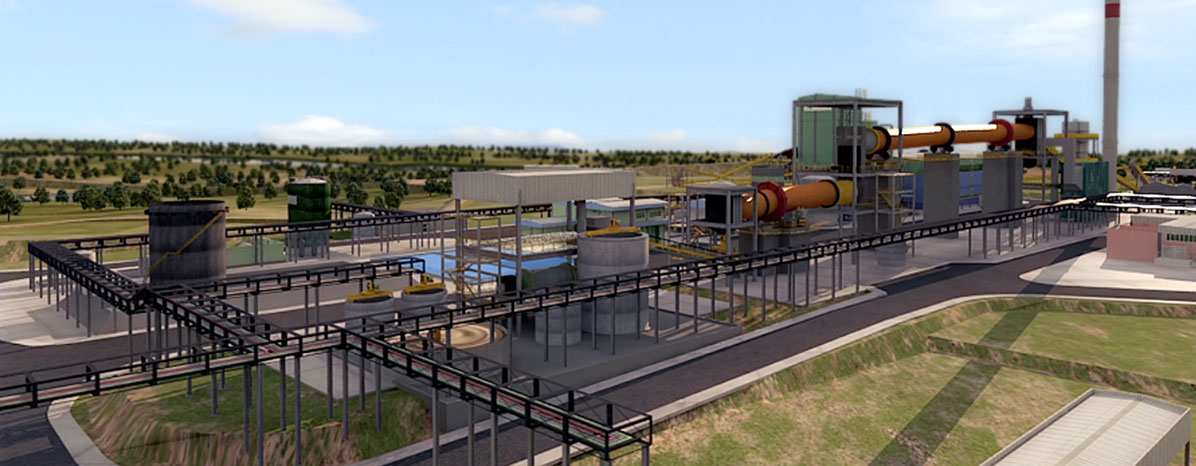

Called Project Vanadio, the vanadium pentoxide (V2O5) mining project in Maracas, Bahia state, about 500 miles northeast of the capital of Brasilia, yields over 10,000 metric tons a year of raw material mined from deposits that extend for 70 kilometers averaging about 1.2 kilometers in width.

Vanadium is an important alloying element in high-strength steel and has many applications as a catalyst in chemical processes. Due to its high coefficient of thermal resistance, vanadium is also being used as a detector material for thermal imaging.

Largo Resources, a Canada-based mining company with vanadium and tungsten projects in Brazil and Canada, owns the project and recently reported construction continues to progress rapidly, on budget and on schedule for commissioning at the end of the year.

Promon contacted AVEVA Group plc, a provider of 3D engineering, design, and information management software to the process plant, power and marine industries, to ask about its design and engineering software – AVEVA NET and AVEVA PDMS – and adoption of AVEVA’s Integrated Project Execution strategy.

“This is a key project for Promon Engenharia and hugely important in the mining sector,” said Fabio Montrezor, systems engineer at Promon. “During this greenfield project, we are supplying both basic and detailed 3D engineering designs through the use of AVEVA PDMS. We are then able to share all file formats across the web in a secure way via AVEVA NET. All people working on the project have access to the appropriate data at each stage of design and construction. Thanks to the adoption of AVEVA’s Integrated Project Execution strategy using AVEVA software we can organize all elements of procurement, construction, inspection and management, ensuring that all project data is up to date.”

.jpg.small.400x400.jpg)