.jpg)

Surfaced barely scratched on 4D BIM safety applications for construction firms

North American construction companies are reporting higher project ROI, less injuries and faster production after implementing safety programs such as building information modeling (BIM), according to a new survey by McGraw Hill Construction.

When McGraw-Hill Construction began researching BIM in 2007 it was still an emerging trend with industry-wide adoption at 28 percent. A report by the company earlier this year found that number is now 71 percent.

The increased efficiency of BIM is credited with cutting labor expenses and material costs for engineers and contractors as well as providing off-site fabrication capabilities and better schedule compression.

In fact, contractors are now leading all construction firm types in the adoption of BIM. And, 49 percent of BIM users report positive ROI compared to 30 percent of non-users, McGraw-Hill’s new Safety Management in the Construction Industry SmartMarket Report shows.

The report is based on responses from 263 general contractors, specialty contractors and engineering firms.

BIM linked to safety management

The new report reveals the use of BIM is linked with strong safety practices with 43 percent of respondents report BIM having a positive impact on project safety.

Model-driven prefabrication is one example of a BIM-enabled process that has strong safety implications. The report said construction companies using BIM have much higher adoption levels of nearly all the safety practices measured in the survey.

“New technologies such as BIM have enabled projects to become more complex, therefore it is essential for contractors to have a fully integrated extensive safety program that can respond to evolving industry needs and allow them to stay competitive,” the report said.

Top BIM functions for improving safety

For 47 percent of construction companies using BIM, the ability to identify site hazards before construction begins is the most effective BIM function for improving safety. The statistic mirrors previous findings showing safety practices directly related to the jobsite are the most highly valued by contractors.

The second leading BIM function for improving safety, according to the survey’s results, is clash detection. Almost a quarter of respondents (23 percent) said finding clashes in advance rather than onsite prevents potentially dangerous situations with workers from different trades in one area.

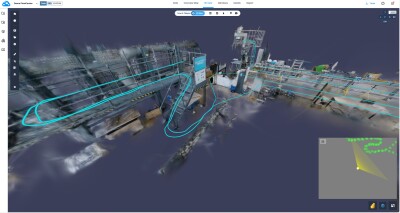

3D and 4D modeling

Just 12 percent said the ability to create 3D images is the most important BIM function for improving safety, according to the report, and only 6 percent consider understanding the designer’s intent as a critical way to promote safety.

Meanwhile, 4D models – which link 3D models to a project schedule – are also proving to be a valuable construction tool, but they are still perceived as difficult to implement, keeping their use limited, according to the report.

Still, their potential to save costs, lives and time for contractors is becoming clearer. Architecture, engineering and construction firms around the globe are looking at innovative ways to leverage 4D modeling in BIM to visualize construction sequences and processes at a high level of detail with the goal of improving construction safety.

“It seems that the safety applications for 4D BIM are as varied as the span of activities related to construction projects,” the report said.

Georgia Tech shows off 4D BIM

At Georgia Tech, professors Jochen Teizer and Chuck Eastman are developing rule-checking software that applies OSHA requirements to 4D BIM models to identify temporary conditions such as stairs without railings and pour breaks in slabs.

“We catch slab edges without wall barriers, openings in walls that have a non-safe sill and holes in slabs that people or things can fall through,” Eastman said in the report.

In a second step, the application will identify the corrective action and inserts it into the schedule for implementation.

As a testament to its potential, their technology won the first BIM & Safety Competition, sponsored by the International Council for Research and Innovation in Building and Construction.

“The more complex the task, the more powerful the effect BIM models can have,” said Charlie Bird, loss prevention director for Balfour Beatty, said in the report. “So far, we’ve used these models to explain safer methods for site excavations, trenching, benching and access, but the applications are nearly endless.”

Check out Balfour’s video explaining the use of BIM to improve safety.

BIM software

BIM software is used by 42 percent of large firms (500 employees or more). But a significantly larger percentage of big firms report using not just BIM software but project management sharing software, a 37 percent increase over the previous report.

Mobile devices on the jobsite

Mobile devices integrated in the workflow of a project are nearly ubiquitous on jobsites with 88 percent of respondents reporting using mobile tools on their projects, up from 76 percent in 2011.

However, the report said the number of firms saying they intend to use mobile devices onsite in the future falls to 84 percent, suggesting adoption has reached a saturation point for current devices. Devices believed by respondents to have the greatest impact on safety are:

- 82 percent – smartphones (other than iPhone)

- 81 percent – iPad

- 78 percent – iPhone

- 68 percent – GPS device

BIM users are also using mobile devices on jobsites at about the same level as non-BIM users, but BIM users take advantage of more tools on mobile devices than non-users.

Tools used on mobile devices on job sites:

- Cameras – 89 percent

- Project Document Sharing – 54 percent

- GPS – 51 percent

- Scheduling – 41 percent

- Project Management Apps/Software – 38 percent

Just 16 percent of respondents reported using 3D CAD tools on mobile devices and just 12 percent of respondents were using BIM tools on their devices.

To download a copy of the report, click here.