At Bentley’s Year in Infrastructure 2018, the company announced a number of individual product updates. But the big news was Bentley’s new iTwin Services, a platform that combines a number of new and existing Bentley technologies to facilitate the creation of data-rich digital twins for your assets.

Some digital twin context

A digital twin, as you likely know, is a digital representation of a physical asset. Bentley specifies that a worthwhile digital twin must be more than a solo 3D model or BIM, it should be a reflection of both the asset’s physical reality (its current 3D-captured conditions) and its “virtuality,” or engineering data.

When a digital twin reflects both flavors of reality in perfect alignment, the company says, it enables users to visualize the historical and real-time conditions of a physical asset, apply analytics to gain insights into the asset’s operation, and even apply AI and machine learning algorithms to predict future states. All of this information can enable more efficient operation for the duration of the asset lifecycle.

How to make and use a digital twin with Bentley’s iTwin Services

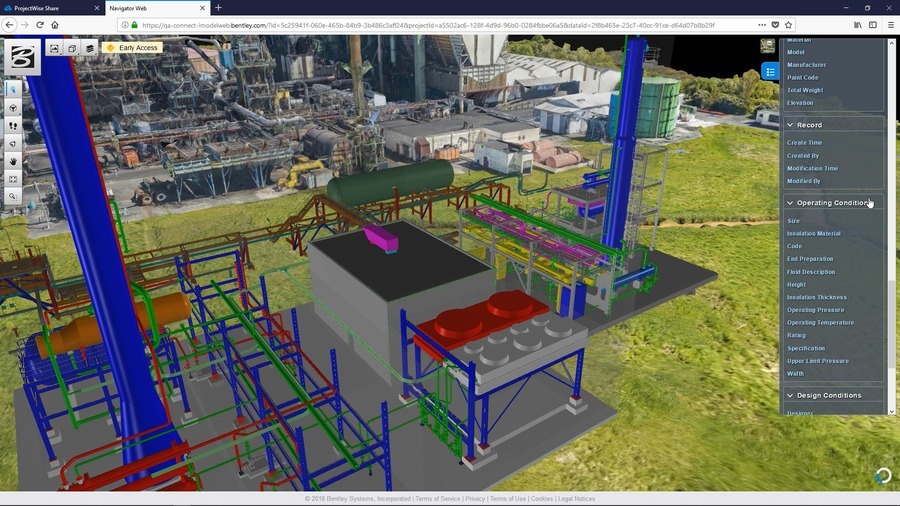

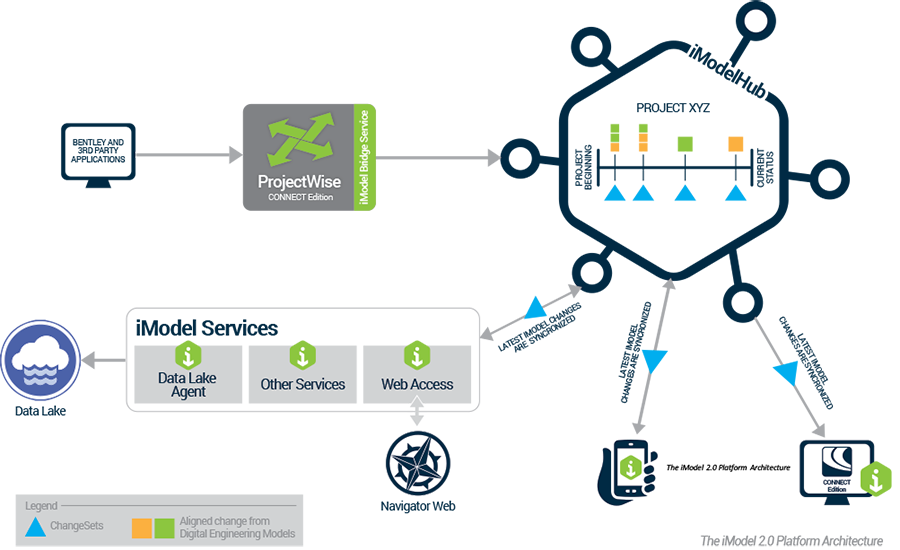

iTwin Services are available to any users of Bentley’s software ecosystem. “Instantiate” a digital twin (Bentley’s term) and the cloud-based service will create a comprehensive iModel for your project, combining available Context Capture 3D data and project engineering data using iModelHub.

The iTwin service will continue to keep both 3D data and engineering data up to date as new changes come in, recording each change to a ledger. This means Bentley’s iTwin Services offer a record of every change made throughout the project, enable project reviews for any stage of the project timeline, and offer visualization and analytics for any changes between different project states. The iTwin Services will also integrate with Bentley’s SYNCHRO 4D construction modeling application.

Bentley focused on aligning the engineering information to the 3D model in their presentations, but specified that this could be any number of data types. The company stressed that working with iModelHub allows you to align a variety of data types to your 3D model–including IoT connected sensors–making it a platform for building the digital twin that works for your purposes.

iTwin services will be available in early 2019, priced according to scale of data, and will include cloud provisioning and web accessibility.

Let Bentley and Atos make a digital twin for you

For those who lack the time, resources, or expertise to gather engineering data, perform 3D scans, and so on, Bentley has announced a strategic partnership that will enable them to create and operate digital twins on your behalf. In cooperation with Atos, Bentley is can supply you with full immersive visibility of assets using drone scanning, real-time monitoring, performance analysis, remote operation of assets, and operational training.

How Bentley tech works together to make it happen

As I’ve described it above, the process of making a digital twin sounds simple enough. However, there’s a lot going on underneath the hood. Here’s a quick breakdown.

The most obvious requirement for creating this digital twin is a good 3D model of the asset’s current physical conditions. Bentley fills this need with its Context Capture product. Though the company announced a number of upgrades to the technology (SPAR will cover these in depth next week), just know that Context Capture enables users to capture 3D models of their assets using handheld cameras, drones, laser scanners, and a variety of sensors.

The next requirement is the merging of that 3D data with whatever engineering data you want to include in your digital twin. This presents a challenge: This data tends to be “dark,” which is a term Bentley borrows from Gartner to describe information that can be accessed only from within the application that created the file. Data in the file format for application A is “dark,” for instance, because it cannot be accessed by applications B, C, and so on.

Bentley explains that engineering information is often dark because it is stored in “opaque engineering files or unintelligent document formats” that cannot be accessed from within the 3D reality model. As such, it tends to be underutilized throughout the asset’s lifecycle.

To solve this challenge, the company looked to its iModel format, which is designed to correlate data stored in different formats. As AEC Mag helpfully explained it last year, iModel processes each file type to line up units, thus ensuring that every one uses centigrade to indicate temperature, and radians, and meters, and so on. Once all your file types are aligned, they can be connected and used in programs across Bentley’s portfolio for a variety of tasks. This enables Bentley to align it to the 3D model for the creation of digital twin.

But there’s another challenge, of course: recording change. For a long time, a user would have to process a whole new version of their model each time a fundamental file was changed by another user on the project. The iModel solves this challenge by recording changes using a ledger that other models can read from, enabling these models to synchronize themselves to the latest state without a great deal of processing.

Admittedly, even the above description is a serious simplification. For those of you who want to know about each little process at work in the iModel, I recommend digging into AEC Mag’s great article here.

For the rest of you, just know that iModel makes it much easier (and faster) to process changes to a digital twin and keep the information—whether it be IoT sensor data, engineering data, 3D capture data—up to date. In other words, it makes the digital twin a worthwhile investment.

For more information about any of the above products, check out Bentley’s website here.