Just what is the ‘Smart Scanning’ method?

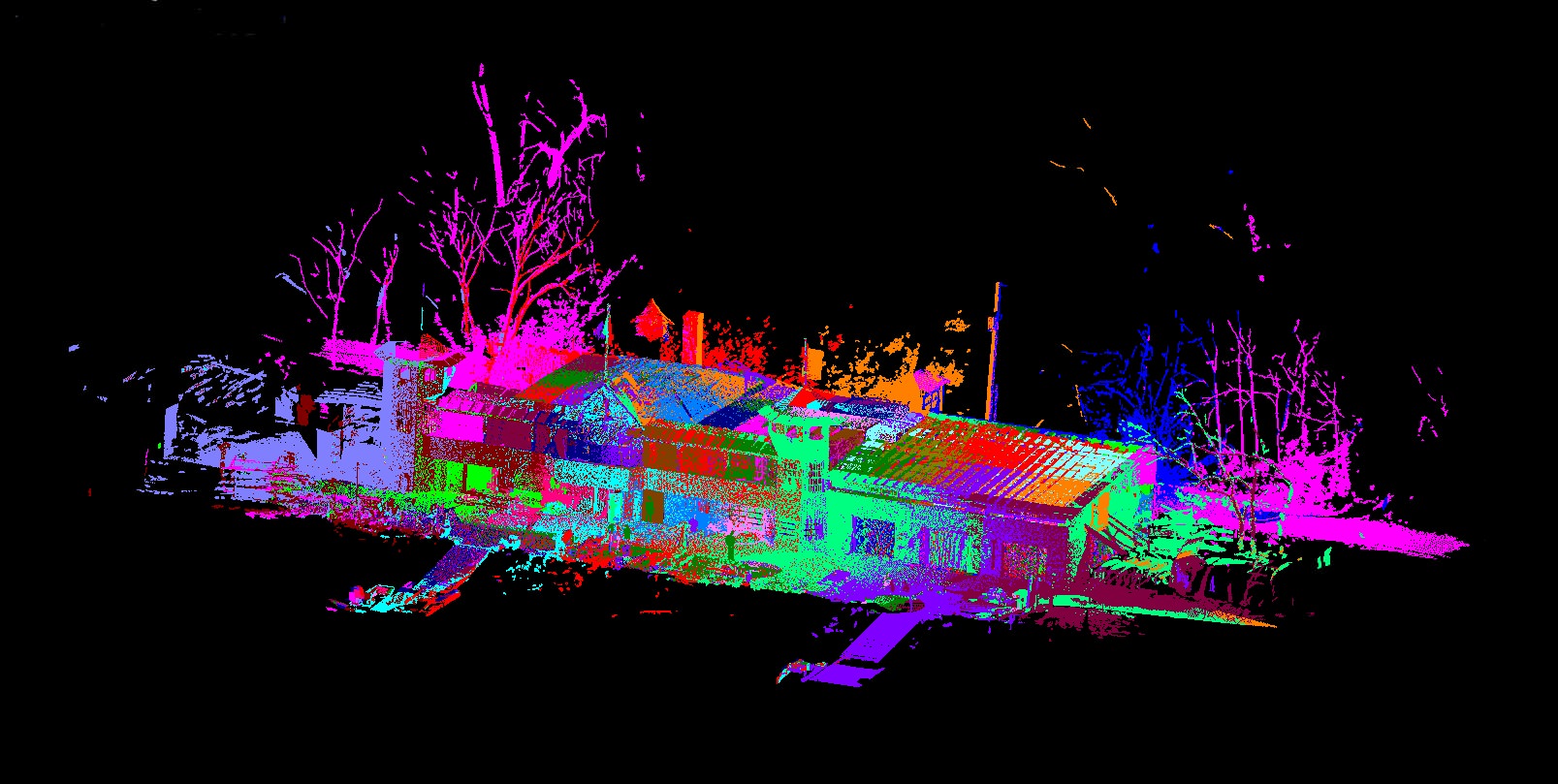

NEWPORT NEWS, Va. – Just a few months after parent firm Automated Precision, Inc., inked an OEM deal with Surphaser-maker Basis Software, API Services is already putting the machine to work with a new scanning workflow it’s calling “Smart Scanning” and using to approach the terrestrial scanning marketplace with a message of accuracy and speed.

API has other scanners in its arsenal as well, said Brent Collier, API Services marketing manager, but the Surphaser is at the heart of a new combination of software and laser trackers that allows API Services to register their scans in real time, doing field validation with similar methods to those recently unveiled by Allpoint Systems, and therefore leave a job site with a complete picture of the entire captured point cloud. Further, “there are no targets,” said Collier. “We don’t have to put up targets because using the laser tracker we can shoot the scanner, and know exactly where the scanner is … Then, when we move the scanner, with the laser tracker in the same position, we can then know where exactly the scanner head is, so the scans come in exactly where they are. We always know where it is in space.”

This also allows them to jump from room to room, using the scanner as a monument and the tracker to understand location. And here’s how they tout the tracker in the literature: “We use interferometers (IFM)—a NIST-authenticated first-level artifact—in our trackers. Nothing is more precise or more trusted than an interferometer. No other scanning method uses an IFM-based laser tracker in its process. All of our tools are integrated in a patent pending process that virtually eliminates targeting and operator-induced errors.”

This is the kind of language that shouldn’t be surprising coming from a company with roots in the metrology space rather than traditional survey. “We’re used to working in accuracies of microns,” joked Collier, “so if we’re ten thousandths off, we’re, like ooh, something’s wrong.” However, he’s quick to note that no workflow is going to overcome the inherent inaccuracies in any measuring device. They’re not claiming to make the actual Surphaser (or any other scanner) more accurate than the specs indicate, just that they’re getting everything possible out of the instrument.

“With this scanning process,” said Collier, “we’re trying to come up with ways that are quicker than traditional methods, and we know in the field that we’ve gotten everything. There’s no getting home and realizing that you need to go back and reshoot. It takes the guesswork out of it. We can see it.”

In fact, API Services are using SpatialAnalyzer, a software coming from the metrology space, as a lynchpin in the workflow (it was also notably just purchased by Hexagon; API are right down the road, good colleagues of New River Kinematics, and Collier said all signs point to very little Hexagon meddling). However, “I’m sure we cold use other programs,” Collier said. And other scanners work, too. It’s the workflow and laser trackers that are unique, and it’s a process that works with metrology instruments like laser arms as well.

Early success has come with the nuclear industry, where getting in and out quickly is paramount and where they know a thing or two about precise measurement, but API plans to approach the rest of the plant and process industry, AEC jobs of all kinds, and, really, any other area where they think they can provide value with laser scanning.

“We aim to save time and headache,” said Collier. “We don’t have to say, ‘give us a week.’ We can do it right there and hand it over.”