Digital twins are virtual representations of physical systems that integrate real-world data to provide a real-time copy of a facility, with new changes updated as conditions change. Digital twins can be powerful tools for managing real-world assets, but they can also be challenging, complex, and time-consuming to create.

At AWS Summit San Francisco, Amazon Web Services (AWS) announced that they are releasing a new digital twin creation tool - AWS IoT Twin Maker - generally available for public use. The new service is aimed at facilitating the development of digital twins for buildings, industrial equipment, and other production facilities.

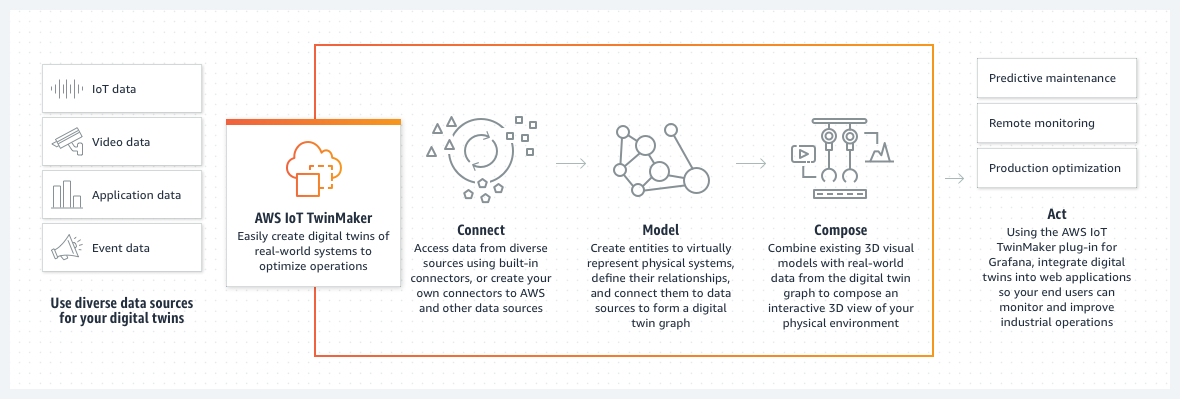

Many industrial companies are already collecting and processing data about their facilities, but collecting separate streams of data is not the same as integrating them into a single stream of information (e.g., the digital twin). With sources as varied as equipment sensors, video cameras and other records, this can present a daunting task. To build digital twins, customers typically manually connect different types of data from diverse sources, then create a knowledge graph that provides common access to all the connected data and maps the relationships between the data sources to the physical environment.

To complete the digital twin, this information is then paired with a 3D virtual representation of their physical systems (e.g., buildings, factories, equipment, production lines, etc.). By adding the real-world data to the 3D visualization, only then is the digital twin kept up to date as conditions change. Customers can import existing 3D models (e.g., CAD and BIM files, point cloud scans) directly into AWS IoT TwinMaker to create 3D visualizations of the physical system and overlay the data from the knowledge graph onto the 3D visualizations to create the digital twin.

Once a company has a virtual representation of its real-world systems with real-time data, they can build applications for operators and maintenance engineers, or leverage machine learning and analytics to extract insights about the real-time operational performance of their systems. Because the work required to get to this level is complex, the vast majority of organizations are unable to fully leverage digital twins to improve their operations.

The goal of AWS IoT TwinMaker to make it significantly faster and easier to create digital twins of real-world systems, and actually getting its customers to a place where they can get to actionable information.

AWS joins several competitors in the digital twin platform space, including some major players like Microsoft Azure, General Electric, Siemens, IBM, Cisco, Oracle, Dassault Systems and Bentley Systems iTwin platform.

AWS IoT TwinMaker is likely looking to stand out in this crowd by streamlining this complex process, by letting developers start by integrating the varying data sources through built-in connectors that are designed to draw in different types of data from disparate sources.

AWS IoT TwinMaker contains built-in connectors for Amazon Simple Storage Service (Amazon S3), AWS IoT SiteWise, and Amazon Kinesis Video Streams (or customers can add their own connectors for data sources like Amazon Timestream, Snowflake, and Siemens MindSphere) making it possible to gather data from a variety of sources. AWS IoT TwinMaker also automatically creates a knowledge graph that combines and understands the relationships of the connected data sources, so it can update the digital twin with real-time information from the system being modeled.

Once the digital twin has been created, developers can use an AWS IoT TwinMaker plugin for Amazon Managed Grafana to create a web-based application that displays the digital twin on the devices plant operators and maintenance engineers use to monitor and inspect facilities and industrial systems, for example:

Developers can create a virtual representation of a metals processing plant by associating data from the plant’s equipment sensors with real-time video of the various machines in operation and the maintenance history of those machines. Developers can then set up rules to alert plant operators when anomalies in the plant’s furnace are detected (e.g., temperature threshold has been breached) and display those anomalies on a 3D representation of the plant with real-time video from the furnaces, which can help operators make quick decisions on predictive maintenance before a furnace fails.

The service is generally available now in Amazon’s US East (N. Virginia), US West (Oregon), Asia Pacific (Singapore), Asia Pacific (Sydney), Europe (Frankfurt) and Europe (Ireland) regions, with availability in additional AWS Regions coming soon.

With AWS IoT TwinMaker, the pricing is usage-based. There are no upfront fees, no required minimum commitments, and no long-term contracts. Customers are charged at the end of the month for their usage. More information on the pricing (including a calculator to estimate costs for different scenarios) are available on the AWS website.