At last year’s Geospatial Content Solutions User Group, Leica Geosystems, part of Hexagon, introduced the Leica DMC-4 airborne imaging sensor. This upgrade to its imaging instruments delivers maximum image fidelity by leveraging mechanical forward motion compensation (FMC) as one of its capabilities. To give us some more information about what’s going on “under the hood” and how their systems are evolving, Geo Week News spoke to Layton Hobbs, Product Line Director for Airborne Solutions at Hexagon.

Can you provide us with some background on what drove the DMC-4’s development?

to reduce blur and enhance image quality

We have been working with new technology that has already been embedded in the Leica CityMapper for several years and more recently in the Leica ContentMapper. The core technology is a sensor module called MFC150. At 150 megapixels, the MFC150 can be configured in different way depending on the application. For example, the CityMapper-2 includes four oblique cameras for city modeling, while the DMC-4 cameras face downward for photogrammetric and orthoimagery applications. The MFC150 creates high-quality imagery, which is important in and of itself, but it also provides a stable calibration and is very accurate for photogrammetry.

We wanted to leverage what we learned with the MFC150 technology and other sensors by applying it to the large-format camera market. With the DMC-4, we ported the MFC150’s proven technology over to replace our existing large-format solution, the DMC III.

Compared to the previous model, DMC III, do you see the DMC-4 as an incremental improvement or more of a rethinking of the technology?

Maybe a little bit of both. From an incremental standpoint, the DMC III is still a very popular system and we have happy customers out there using the system. In the DMC-4, we’ve kept a lot of the subsystems’ technologies that already worked really well: the flight management systems, the path technology, the gyro-stabilized mount technology. From that perspective, the innovation is incremental.

However, by implementing the MFC150s and the configurations around them, we’re improving the technology and significantly enhancing efficiencies. The new DMC-4 cross-track pixel count is about 20% more than the DMC III, that equates directly to a 20% efficiency gain in terms of the number of flights that are needed to collect a given area at the same resolution. Additionally, the MFC150s also enable a faster frame rate, more than two times faster: as you’re flying along, the DMC-4 can take twice as many photos. Or, you can fly twice as fast and collect the same number of photos.

According to feedback from customers, they are seeing productivity gains of 25-30% and more compared to the DMC III by combining the DMC-4’s cross-track pixel count efficiency gains with its faster frame rates.

One of the obvious benefits for our existing customers is that the workflow will be the same as what they’ve already used. In fact, we have customers who might be flying LiDAR or city mapping projects with our CityMapper-2 or TerrainMapper-2 systems. The DMC-4 will be an easy transition for them because Leica HxMap is a one-stop software solution for all our sensors. So HxMap brings some benefits in terms of investment around training and licensing. New customers who have not yet been exposed to HxMap will appreciate how easily scalable our solution is in terms of high-performance computing. HxMap utilizes a distributed processing environment, so depending on the amount of data you need to process, you can scale up or down in hardware or the number of CPUs that you need, and adjust the software to match your network. The goal is to provide an end-to-end solution, and we are constantly adding new capabilities to HxMap which customers can already leverage.

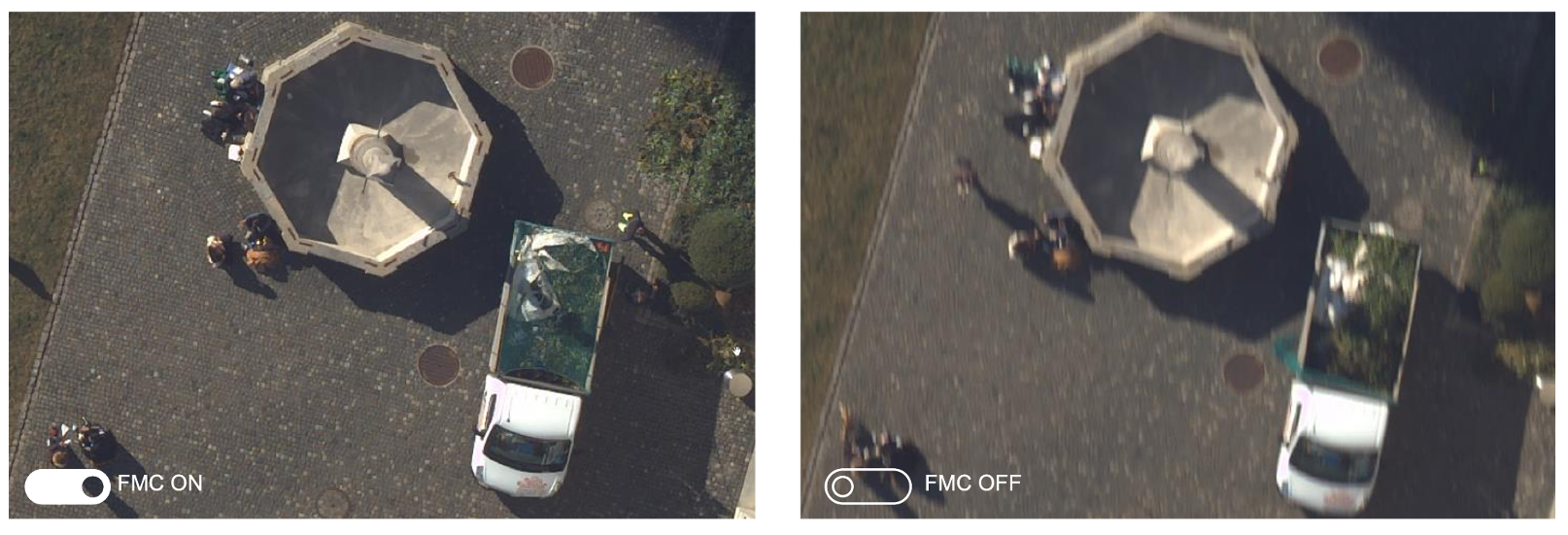

The new sensor is equipped with mechanical forward-motion-compensation (FMC) — can you explain the benefits of FMC?

Forward motion is typically a large contributor to blur in an uncompensated system. There are other movements, such as the aircraft moving through the air, but our gyro-stabilized mount removes most of that.

Forward motion compensation is somewhat what it sounds like: it’s compensating for the forward motion of the aircraft whenever the image is taken. So, at the time the camera shutter opens, it allows a certain amount of light in and then closes back up. In the amount of time that the shutter is open, especially in an aircraft, it can translate to several pixels of movement. So, depending on lighting conditions and speed, you might have 10 or so pixels of motion that occurred during the time the shutter was open. For us, the most sensible way to address this is to move the camera during the time the shutter is open. We mechanically compensate the forward motion by moving the backplane of the camera to match the speed of the aircraft in order to eliminate that pixel movement.

Another approach to solving the forward motion blur is to only open the shutter for a very short amount of time. However, modern CMOS sensors are designed to operate optimally with adequate exposure time. They do a great job of collecting great radiometry, rich color details and feature information on the ground. By limiting the sensor with very fast shutter speeds, you're not taking full advantage of all the technology within the camera system. The FMC gives us the benefit of allowing the shutter to stay open for the optimal amount of time, rather than having to shorten it to correct for forward motion. It's also allowing the camera to operate at its maximum performance level, which gives us all kinds of other benefits, such as good color saturation and low noise data.

What types of users do you think will benefit the most from the DMC-4’s capabilities?

There’s a wide range of uses for large-format cameras. It’s a versatile technology: you can do traditional photogrammetry, ortho imagery, high-resolution feature mapping or other GIS applications. Our typical DMC-4 customers are photogrammetry companies who do traditional map extraction, 3D terrain mapping, ortho imagery or GIS. These customers may also be operating a LiDAR system depending on their project requirements.

What can users expect to be able to do now with the DMC-4 that they might not have been able to do previously?

The DMC-4 offers the additional pixel count and frame rate. Because the DMC-4 is a modular system and we’re also using modular imaging components with the MFC150, it is to a certain extent future-proof. The DMC III system is almost 10 years old and we continually try to evolve its technology. Because the DMC-4 is modular, we can create a new module or upgrade the existing module if better technology, say for imaging, comes along. The DMC-4 can be adapted if other applications which require a completely different type of sensor emerge in the coming years. The modular approach is probably the key benefit of the DMC-4, that makes it different from where we were in the past.

What excites you most about this release?

For me, the one thing that’s really exciting is the positive response we are getting from not only our customers, but also the broader industry about this release. We understand that our foundation as a company was around camera systems, and around the best performing aerial imaging systems, and we’re still at the forefront of this market because we understand what our customers need. I think it is a really exciting time for this technology, especially for new customers that haven’t yet felt the benefit of our technology, and we’re thrilled to be on this journey with them.