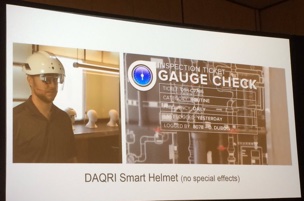

An unaltered feed from the DAQRI Smart Helmet

During Autodesk’s Construction Launchpad event this morning, company execs discussed the different ways that technology is disrupting the construction industry—and what conversation about disruption would be complete without touching on augmented reality? As part of the proceedings Brian Mullins, CEO of DAQRI, took the stage to discuss how the technology is moving forward from being a toy to being a real tool.

Mullins started by explaining DAQRI’s maine product, the Smart Helmet, which is a hard hat with a visor that doubles as a view screen and projects digital information onto the wearer’s view of the real world. Our own Sam Billingsley wrote about it earlier this year.

Mullins said that he sees this kind of augmented reality technology as a “really exciting way to empower workers.” It does this because it connects people to the information around them and helps to redefine what day-to-day work can look like in an industrial or construction working environment. He then answered the question on everyone’s mind: “What does this look like?”

This might involve, for instance, projecting digital work instructions on top of materials or equipment that a worker is using for a particular job. The technology allows you can present complicated information to a user to teach them how to do something very complex that they didn’t know how to do before. It teaches the user on the spot. The helmets can also include other sensors, depending on the applications they’re used for, like a thermal camera to help detect leaks in pipes.

But that’s just the start of it. Mullins showed a video (below) of a steel mill in Kazakhstan that is testing DAQRI’s smart helmet. This is already helping them to solve business problems by curating the data that it presents to the user. In other words, it gives them actionable information by winnowing all the available data down so that the user only sees what’s necessary to make the decision at hand and get their job done more efficiently. According to Mullins, workers using DAQRI’s solution are seeing up to a 40% increase in efficiency.

What Makes DAQRI’s Helmet a Real Tool?

This is all fine and good, but there are other augmented reality technologies that might be able to do the same thing, like Microsoft’s HoloLens. So what sets DAQRI apart? Mullins emphasizes that DAQRI’s main focus is on the construction, oil & gas, and industrial facilities verticals, as well as other high-risk, critical workspaces.

They’ve elevate the Smart Helmet from “distraction” to “tool” by focusing on the needs of this space, he says, including meeting OSHA requirements, and incorporating the technology into a piece of equipment that workers already wear every day: a hard helmet. A HoloLens might be very useful in the office, but you can’t wear it at the same time as a hard helmet. They’ve also focused on making it comfortable, and ensuring that the battery lasts for the full 12-hour work day.

DAQRI, he says, has also paid attention to the workflows proper to these spaces. This means that their technology works with your existing BIM software without you having to hire any outside developers to stitch the two together. Where the success of a technology often relies on your ability to slip it into your workflow seamlessly, this is a big deal.

Mullins closed by offering a view of DAQRI’s next steps. In 2015, they shipped off developer’s kits, and started using them in real work environments like that steel mill in Kazakhstan. With the feedback they’ve been getting, the company is looking to release a new version of the Smart Helmet in the next three months.

If you’ve been keeping your eye on augmented reality technology, your time is almost here.