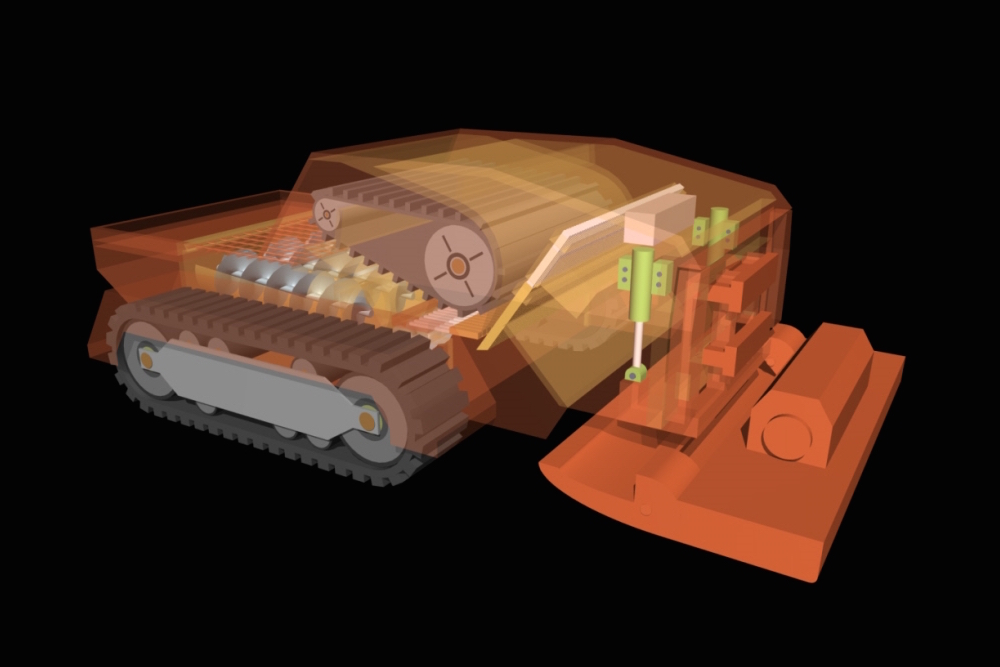

A rendering of Advanced Paving Technologies’ 3D-paving machine

We all understand that 3D technologies are great at solving problems. But, if we’re being honest with ourselves, we don’t always do the greatest job of communicating that fact.

Maybe we’re too enamored with the abilities of the technologies—level of accuracy, scan density, distance, etc. We in this industry have developed a nasty habit of selling our technology to each other rather than the asset owner, the manager, or the owner/operator. We sell the technology to other tech-heads like ourselves rather than the people who hold the purse strings to buy this stuff.

These people care less about specs and more about what problems the technology can solve for them. For the most part, we’ve been pretty bad at telling them.

If we want a model for how to do a better job, this project presentation from Advanced Paving Technologies is a place to start. The value proposition is clear in the way the website is designed: There is a section for “The Problem,” and one for “Our Solution.” If you read the two short, picture-heavy descriptions, you’ll have a full understanding of how 3D technology will save money, time, re-work, and frustration. It makes the technology feel like magic–a lot more than a description about spinning mirrors and wavelengths does, anyway.

The Problem With Paving

As the website describes, “Current 2-D asphalt paving machines, with their flat screeds, are only adequate when used on a flat surface. They have NO ability to adjust the amount of asphalt that is delivered across the width of the surface to be paved.”

This means that when we’re repaving an old road, every section gets the same amount of asphalt. Damaged sections, like an area that’s collapsed, get the same amount of asphalt as the flat sections. When we run a roller over the asphalt to flatten it, the asphalt in the damaged areas doesn’t get as compacted as the asphalt in the flat areas. It stays softer, so it cracks, breaks, and becomes a hazard. Again. We have to rework it continually to keep the roads safe, flat, and usable.

The Solution

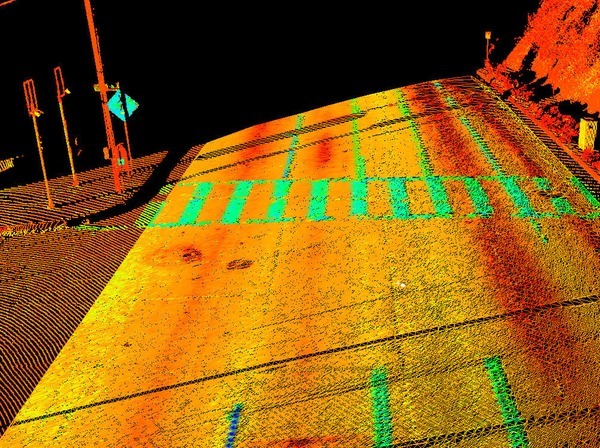

Advanced Paving Technologies breaks out the ol’ LiDAR and scans the road. From there, they build a model of a “3D asphalt mat” that will fill the dips and flatten the bumps. “This will not be a flat layer of asphalt like current 2D asphalt paving machines deliver, instead it will be shaped to inversely mimic the surface being paved providing more asphalt over depressions and less over bumps.”

The 3D asphalt mat model will be input into a special machine that can lay the mat in perfect alignment with the road. The result is a much better fit, and much flatter roads. “With the correct volume of material placed accurately over surface deformations,” the website explains, “we will be able to achieve a much better and more uniform level of compaction. Better compaction will result in extending the life of the road, saving on long term costs.”

This means you won’t have to re-pave it nearly as often. It extends the lifecycle of the road significantly because it makes the road much more resilient to nature and traffic.

Convincing?

I think it’s pretty convincing. If you don’t think so, the video has an even simpler description of the problem and APT’s proposed solution. I bet it would even convince a lot of people who have never heard of LiDAR before.

Maybe APT were forced to put the issue in such clear terms because they’re attempting to raise money on Kickstarter to perform necessary R&D. To survive, the company is entirely dependent not on the tech-heads, but on the largesse of the people holding the purse strings. Then again, I suppose we all are.