Now, finally, 3D printing might be useful for more than making a doll version of yourself. According to an announcement at the Consumer Electronics Show in Las Vegas, the company has partnered with Somerville, MA based Voxel8 to create what they are calling the world’s first 3D electronics printer.

In a blog post, Autodesk wrote that “We believe future electronic devices will be printed rather than assembled. Fabricated layer-by-layer as a single object, rather than assembled from separate parts. Although 3D printing is often associated with throw-away plastic ‘trinkets’, together with Voxel8 we are looking to make functional printed devices a reality. Today we are starting with electronics by enabling the design of 3D wires embedded in printed models.”

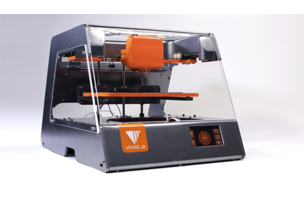

What will Voxel8 provide? Well, the printer itself. On top of that, it will contribute the expertise and innovations of co-founder (and Harvard professor) Jennifer A. Lewis, who has developed a printable conductive silver material for 3D printing that Voxel8 claims is “5000x times more conductive than conductive pasts and filaments currently used in 3D printing.” [http://www.voxel8.co/]

How about Autodesk? For their part, they will supply _Project Wire_, a new software tool they are developing. According to the company, the tool will allow designers and 3D printing enthusiasts to “place components, route 3D wires, and output multi-material print data for fabrication.”

Why 3D Print Electronics? Some benefits of using a 3D printer for printing electronics are obvious (the hope of printing a new remote control to replace the one you lost), and some are less so.

For one, the 3D printer enables designers to ditch the circuit board required by today’s manufacturing techniques because they can embed the circuits directly into the object itself. Autodesk also claims that the flexibility of the system, the ability it gives the designer to build circuits in 3D shapes, will allow designers to fabricate circuits that were not previously possible.

Whether this technology is scalable remains to be seen. After all, we know that a manufacturer wouldn’t want to use a battalion of 3D printers to fabricate their electronic devices. We also know that the average consumer won’t pony up the $8000 necessary to buy one of these things.

Either way, it looks like the start of something new and exciting for 3D printing.