It’s easy to forget that 3D sensors aren’t the only end of the 3D workflow growing by leaps and bounds. Case in point: GE, a company so large that every release refers to it as a “giant,” is offering $1.4 billion to purchase two different European makers of 3D metal-printing machines.

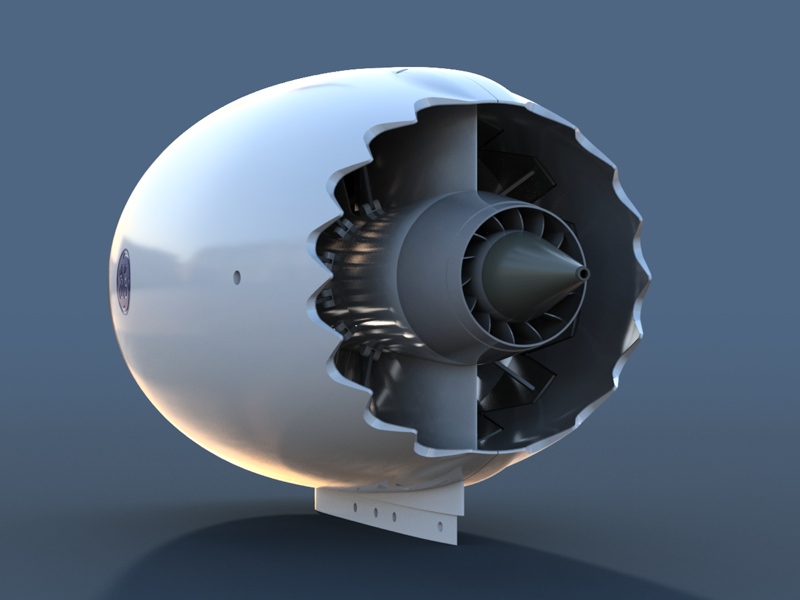

According to the Wall Street Journal, both of these companies manufacture machines that print metal components for use in aircrafts, such as turbines and nozzles.

Why are these two companies worth a combined $1.4 billion? Their 3D-printing technologies enable GE to use a method of inventory management called “just in time” (JIT) manufacturing. Using JIT, GE can produce a part if and when it’s needed, rather than generating extra inventory in advance and then keeping the extra parts on hand in case they’re needed. This reduces labor costs, unused item costs, as well as the cost of space to hold inventory.

The other benefit is the ability to produce parts that are too complex to manufacture using traditional subtractive methods. This includes the fuel nozzles the company is already 3D-printing for new planes manufactured by Boeing and Airbus. GE is also using the technology for parts in its power, oil & gas units.

GE is so bullish on these two companies because the acquisition is “expected to help GE realize $3 billion to $5 billion in efficiency gains across the company over the next 10 years,” according to the Wall Street Journal.

This investment follows the $1.5 billion GE has spent on manufacturing and additive technologies since 2010.